How Are Stamping Metal Parts Powering the Next Generation of Industrial Manufacturing?

2025.11.06

2025.11.06

Industry News

Industry News

In the rapidly evolving landscape of industrial production, efficiency, precision, and versatility have become the cornerstones of success. Among the many technologies driving this transformation, stamping metal parts have emerged as a critical component shaping industries from automotive and aerospace to electronics and construction. Once seen as a traditional manufacturing method, metal stamping has evolved into a sophisticated, high-tech process that enables mass production with unparalleled accuracy and cost efficiency.

What Are Stamping Metal Parts and Why Are They So Important?

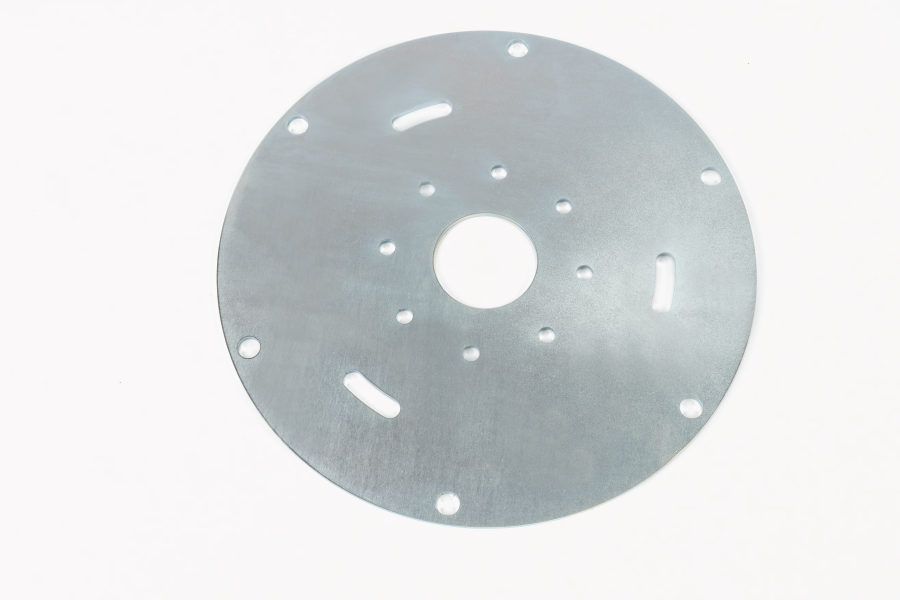

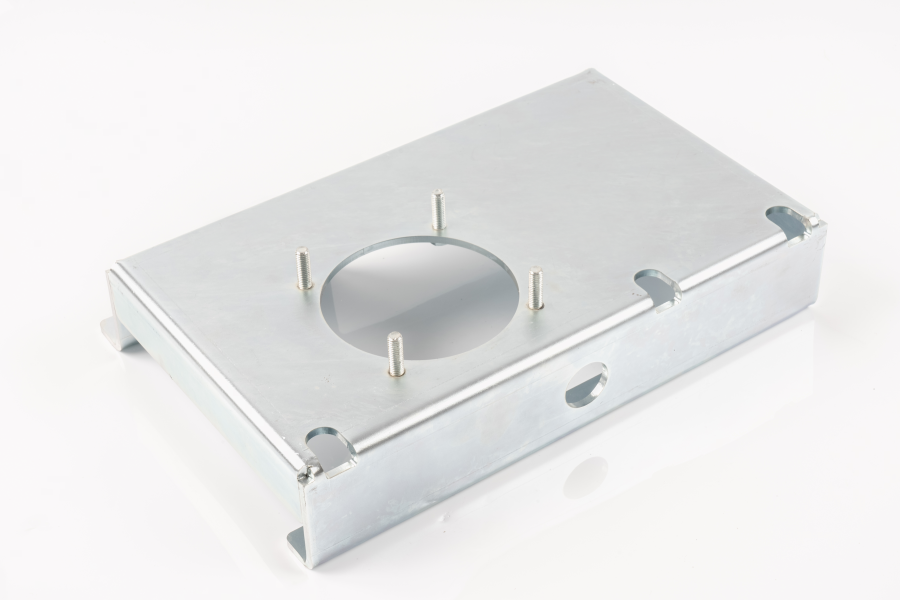

Stamping metal parts are components created through a process that involves pressing or forming sheet metal into desired shapes using a stamping press and custom dies. This manufacturing method allows for the production of complex shapes with high precision and repeatability. The versatility of stamping makes it suitable for producing everything from small electronic connectors to large automotive body panels.

The importance of stamping lies in its efficiency and scalability. It enables manufacturers to produce high volumes of parts quickly while maintaining consistent quality. As industries continue to demand lightweight, durable, and precisely engineered metal components, stamping remains one of the most cost-effective and reliable solutions.

The Evolution of Metal Stamping: From Manual to Intelligent

Traditional metal stamping once relied heavily on manual operations and mechanical presses. Today, however, the process has been revolutionized through automation, robotics, and digital control systems. Modern stamping facilities now use CNC-controlled presses and AI-driven monitoring systems to ensure consistency, reduce waste, and optimize material usage.

Intelligent stamping systems are capable of detecting micro-defects, adjusting pressure in real-time, and tracking production metrics automatically. This integration of smart manufacturing not only improves productivity but also enhances quality assurance—an essential requirement in industries like aerospace and automotive manufacturing.

The Materials Behind High-Quality Stamping Metal Parts

One of the key advantages of metal stamping is its compatibility with a wide range of materials. Commonly used metals include:

| Material | Characteristics | Applications |

|---|---|---|

| Stainless Steel | Corrosion-resistant, durable, and strong | Automotive exhaust systems, appliances, medical devices |

| Aluminum | Lightweight, good conductivity, easy to form | Aerospace, electronics, automotive panels |

| Copper | Excellent conductivity, ductile | Electrical connectors, terminals, motors |

| Brass | Corrosion-resistant, aesthetically appealing | Decorative hardware, valves, precision instruments |

| Carbon Steel | Strong, affordable, easy to process | Industrial machinery, structural parts |

The right choice of material depends on the product’s application and the required performance, whether it’s strength, conductivity, or corrosion resistance.

Why Precision Matters in Stamping

In modern manufacturing, precision is not optional—it’s mandatory. Every stamped part must meet exact specifications to ensure proper assembly and performance. Even the slightest deviation can lead to system inefficiencies or safety risks, especially in high-stakes sectors like aerospace or automotive engineering.

To achieve this, high-precision stamping machines are used, often equipped with laser-guided sensors and optical measurement systems. These technologies allow for dimensional accuracy within microns, guaranteeing that each stamped component meets the most demanding standards.

The Role of Automation and Robotics

Automation has completely redefined the stamping industry. Advanced robotic arms are now integrated into stamping lines for loading, unloading, sorting, and inspection tasks. This automation not only increases production speed but also minimizes human error and enhances workplace safety.

In addition, smart robots powered by machine learning can predict maintenance needs and detect defects in real time, drastically reducing downtime. The integration of robotics with data analytics and IoT (Internet of Things) technology is transforming stamping from a mechanical process into a fully connected, intelligent production system.

Sustainability and Energy Efficiency in Metal Stamping

With growing global awareness of environmental impact, manufacturers are increasingly adopting sustainable stamping practices. Modern stamping systems are designed to minimize material waste by optimizing die design and sheet layout. Additionally, the use of recyclable metals like aluminum and stainless steel supports circular economy principles.

Energy-efficient servo presses are replacing traditional hydraulic systems, reducing power consumption and improving operational control. By adopting green manufacturing methods, companies not only reduce environmental impact but also improve their competitiveness in markets that prioritize sustainability.

Applications Across Multiple Industries

The versatility of stamping metal parts has made them indispensable across numerous sectors:

Automotive: Used in car bodies, frames, exhaust systems, and braking components.

Aerospace: Provides lightweight yet strong components for aircraft structures.

Electronics: Produces connectors, terminals, and shielding components.

Construction: Creates metal brackets, beams, and fixtures with structural strength.

Medical Devices: Supplies precision components for surgical instruments and devices.

Each of these industries relies on stamping technology to deliver consistent, high-quality results that meet stringent performance and safety requirements.

The Economic Impact of Metal Stamping

Metal stamping plays a crucial role in the global manufacturing economy. Its ability to produce large quantities of parts at low cost helps manufacturers remain competitive in international markets. The reduced need for post-processing and the long lifespan of stamping dies further enhance cost efficiency.

Moreover, as global demand for electric vehicles, renewable energy equipment, and smart electronics grows, the need for high-precision stamped metal components continues to rise. The industry’s expansion is expected to contribute significantly to job creation and technological innovation worldwide.

Looking Ahead: The Future of Stamping Metal Parts

The future of stamping metal parts lies in digital transformation and material innovation. As lightweight composite metals and advanced alloys become more prevalent, stamping processes will continue to evolve to handle these new materials efficiently.

Emerging technologies like 3D-printed dies, AI-based predictive maintenance, and real-time data monitoring are further enhancing the flexibility and responsiveness of stamping operations. Manufacturers are also exploring hybrid production models that combine stamping with laser cutting or additive manufacturing for greater customization.

Eng

Eng  中文简体

中文简体