How can high-precision stamping technology reshape the new standard of modern metal manufacturing?

2025.08.06

2025.08.06

Industry News

Industry News

High Precision Stamping technology has achieved a qualitative leap from traditional stamping to precision manufacturing through innovative mold systems, advanced pressure equipment, and intelligent control technology. This article will delve into how high-precision stamping technology can achieve an astonishing production capacity of 100000 pieces per day through multi station progressive dies, deep drawing, and other processes, while ensuring perfect consistency from the first piece to the last piece, providing more precise and economical metal component solutions for various industries.

How can multi station progressive die technology achieve a dual breakthrough in efficiency and accuracy?

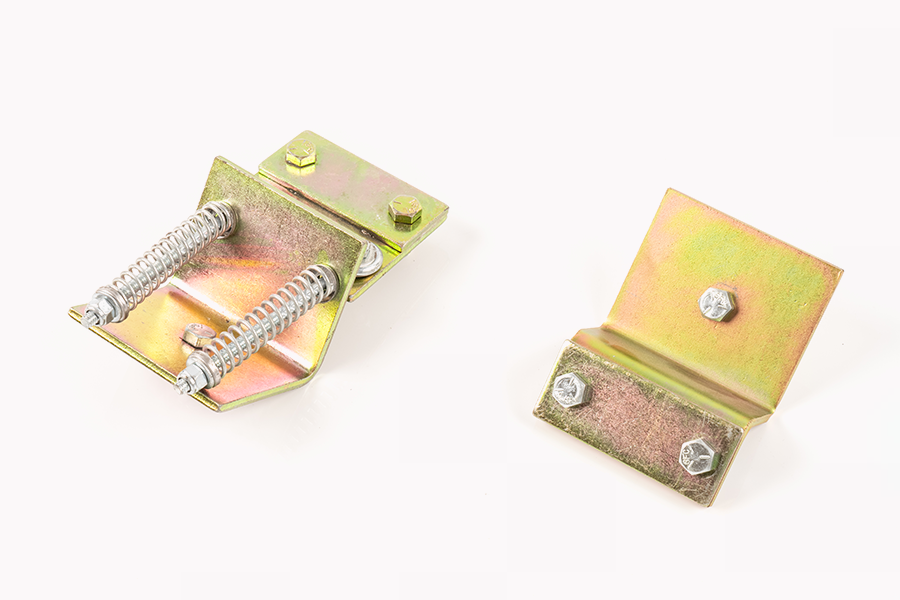

The core of high-precision stamping technology lies in its innovative mold system design. Multi station progressive die technology integrates traditional processing that requires multiple steps into a continuous flow, where materials gradually move within the mold and each station completes a specific forming process. This integrated design not only greatly improves production efficiency, but also significantly improves product accuracy by reducing positioning errors caused by workpiece handling.

In terms of precision control, modern progressive dies adopt micrometer level guidance systems and temperature compensation technology. The precision guide column and guide sleeve are matched with a clearance controlled within 0.005mm, and coupled with a real-time temperature monitoring system, ensure that the mold can maintain stable forming accuracy even in continuous working conditions. This technology is particularly suitable for producing micro parts with complex geometric features, such as precision connectors, micro motor housings, etc.

The improvement in production efficiency is also remarkable. By optimizing the feeding system and process layout, the modern advanced stamping cycle can reach over 100 times per minute, coupled with an automated material collection system, achieving 24-hour uninterrupted production. This efficient production mode enables a daily production capacity of 100000 pieces, while reducing unit costs by over 40%.

How can deep drawing and complex forming break through the technological limits of metal forming?

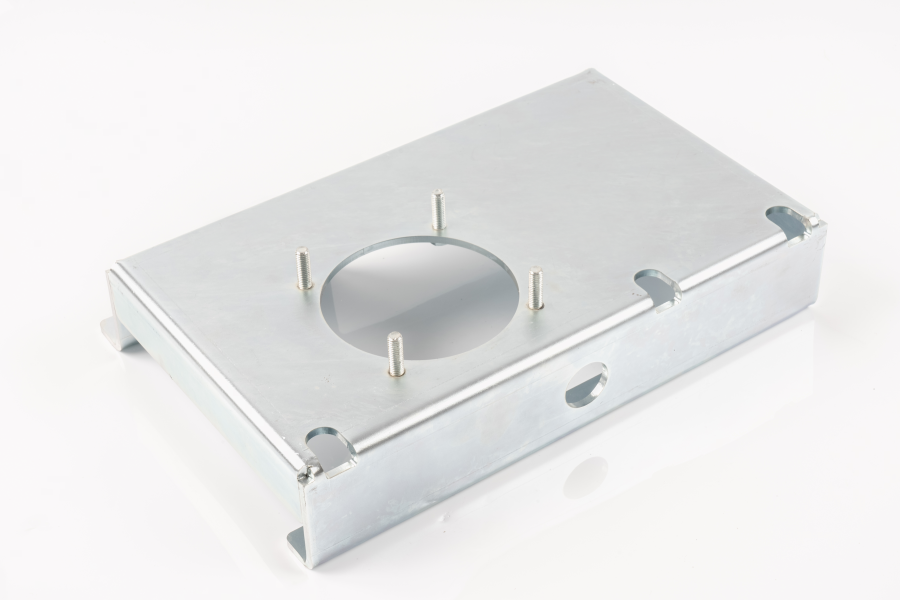

Deep drawing technology is another key process in high-precision stamping, which causes plastic deformation of metal sheets under the action of molds, forming various complex three-dimensional structures. Modern deep drawing technology can form precise features such as multi curved structures and microporous arrays by precisely controlling material flow, meeting the needs of high-end fields such as aerospace and medical equipment.

In terms of process control, the latest hydraulic mechanical composite press is equipped with an intelligent control system that can adjust speed and pressure in real-time throughout the entire forming process. Advanced sensor networks monitor the flow status of materials and dynamically adjust process parameters through closed-loop control algorithms, effectively solving common defects such as wrinkling and cracking in traditional deep drawing. This intelligent process control enables the ultimate stretch ratio of deep stretching to break through traditional limitations and reach unprecedented levels.

In terms of tolerance control, modern high-precision stamping can achieve a dimensional accuracy of ± 0.01mm, and the surface roughness can reach Ra0.4 μ m. This level of precision is sufficient to meet the requirements of the vast majority of precision assemblies, partially replacing traditional mechanical processing techniques. It is worth mentioning that this high-precision product can maintain perfect consistency from the first piece to the last piece, greatly reducing the defect rate of the product.

Why can material diversity and equipment innovation cover the widest range of application needs?

Another major advantage of high-precision stamping technology is its excellent material adaptability. Modern stamping workshops can handle over 30 types of metal materials, including various special materials such as stainless steel, aluminum alloys, copper alloys, etc. We have developed specialized process plans based on the characteristics of different materials, such as multi-stage heat treatment for high-strength steel and surface anti sticking treatment for aluminum alloys.

Equipment innovation is the key to supporting this capability. The investment of large tonnage presses has greatly expanded the processing range, capable of handling everything from micro electronic components to large structural parts. The latest servo pressure technology provides a continuously adjustable pressure curve, which can accurately match the forming energy according to material characteristics and product requirements. The mold processing center in the workshop is equipped with five axis linkage processing equipment, which can manufacture the most complex precision molds.

The intelligent transformation has also brought a qualitative leap in production efficiency. The advanced MES system realizes the digital management of the entire production process, and every link from order issuance to product shipment can be traced. The device networking system monitors the production status in real-time, and predictive maintenance greatly reduces unplanned downtime. These technological innovations have jointly built an intelligent manufacturing ecosystem for high-precision stamping.

Eng

Eng  中文简体

中文简体