How Do High-Precision Stamping Manufacturers Optimize Complex Metal Forming for Large-Scale Production?

2026.01.01

2026.01.01

Industry News

Industry News

In the rapidly evolving landscape of technical manufacturing, the ability to produce intricate metal components with micron-level accuracy is a fundamental requirement for the electronics, automotive, and medical industries. High-precision stamping manufacturers have revolutionized this sector by integrating advanced automation with sophisticated metallurgical techniques. By utilizing a continuous automatic punch press, these facilities can transform raw metal coils into finished, high-complexity parts with unparalleled speed and consistency, meeting the rigorous demands of modern engineering.

Advanced Tooling and Multi-Station Technology

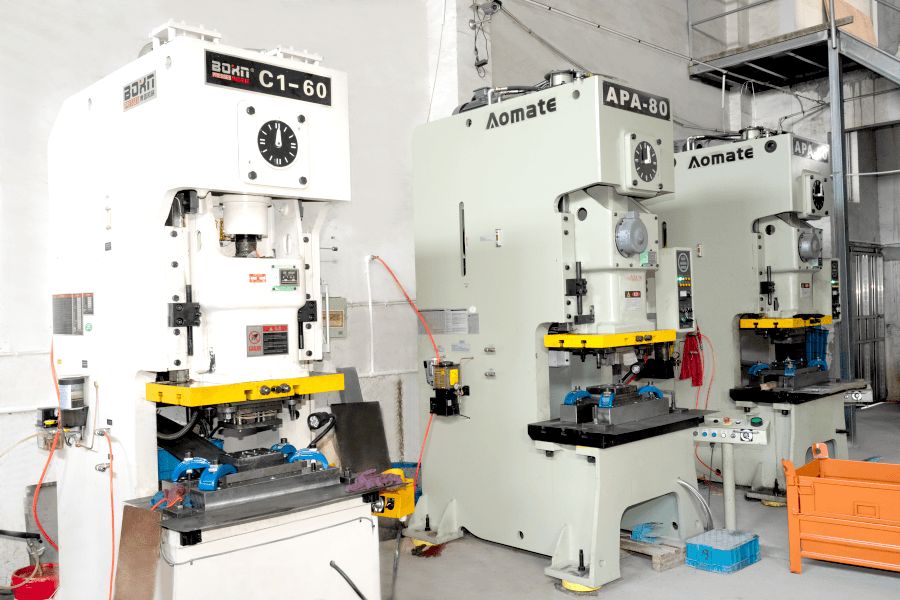

The core strength of leading high-precision stamping manufacturers lies in their versatile tooling capabilities. We rely on multi-station progressive die, progressive die, and single punch die technology to produce precision metal stampings. Unlike traditional single-stage processes, a progressive die allows a single strip of metal to undergo multiple operations—such as cutting, bending, and forming—as it moves through the continuous automatic punch press.

These capabilities enable us to provide excellent accuracy and achieve a single-day production capacity of 100,000 pieces, significantly reducing unit costs. This high-volume output does not come at the expense of quality; the mechanical synchronization of the multi-station dies ensures that every feature is positioned with perfect repeatability. Whether the project requires a simple bracket or a complex connector, the integration of progressive dies within a high-speed press environment allows for the efficient realization of high-density production schedules.

Mastery of Complex Forming and Deep Drawing

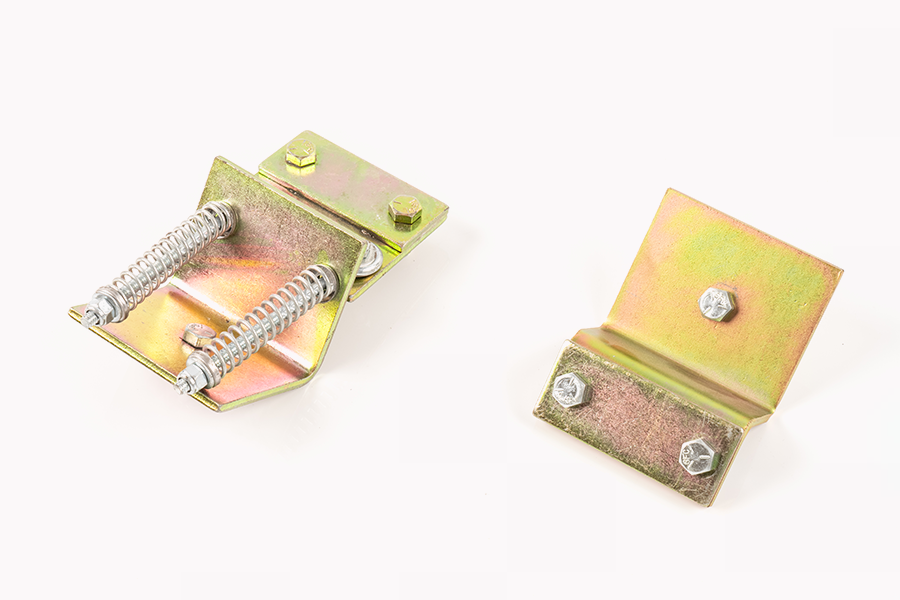

Beyond standard bending and punching, high-precision stamping manufacturers must tackle the challenges of three-dimensional metal flow. Through deep drawing, flanging, punching, and other processes, we can create precision structures such as multi-curved surfaces and micro-hole arrays. Deep drawing, in particular, is an intensive process where a metal blank is radially drawn into a forming die by the mechanical action of a punch, creating hollow, cylindrical, or box-shaped parts.

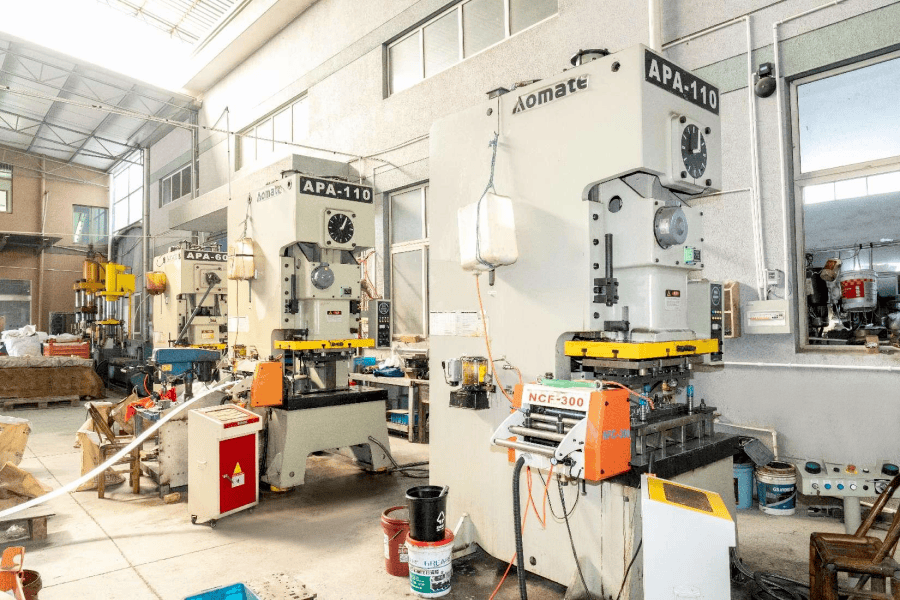

Using a series of hydraulic and mechanical presses and an in-house tool room, we can produce even the most complex deep-drawn stampings with tight tolerances and perfect repeatability from the first piece to the last piece. The ability to maintain uniform wall thickness and structural integrity in deep-drawn parts is a hallmark of industry-leading expertise. Our in-house tool room is essential for this precision, allowing for the immediate adjustment and maintenance of dies to prevent "springback" or material thinning during the high-pressure forming stroke.

Integration of Advanced Press Controls and Software

Modern high-precision stamping manufacturers have moved far beyond simple mechanical levers. In addition to the expertise of our employees, we have invested in large-tonnage presses. These controls have advanced software, sensors, I/O modules, and drives that enable us to change the speed and pressure applied by the die throughout the forming stroke. This level of control is vital when working with sensitive materials or deep-drawn shapes that require a specific velocity profile to avoid tearing.

The continuous automatic punch press systems we utilize are equipped with real-time monitoring sensors. These sensors detect even the slightest deviation in material thickness or die pressure, allowing for instantaneous corrections. Due to continuous investment in equipment and personnel, we have developed industry-leading complex deep drawing capabilities. This synergy between human experience and digital precision ensures that every production run meets the exact specifications provided by our clients.

Technical Capabilities of High-Precision Stamping

The following table details the technical parameters and production capabilities of our high-precision stamping manufacturers facility:

|

Feature Category |

Technical Specification |

Operational Benefit |

|---|---|---|

|

Product Keyword |

High-precision stamping manufacturers |

Micron-level accuracy for complex parts |

|

Equipment Type |

Continuous automatic punch press |

High-speed production up to 100k pcs/day |

|

Tooling Technology |

Multi-station Progressive Die |

Multi-operation forming in a single pass |

|

Core Process |

Deep Drawing & Flanging |

Creation of hollow and multi-curved structures |

|

Material Support |

30-plus Alloys (SS, Al, Cu, etc.) |

Wide material breadth for diverse industries |

|

Control System |

Advanced Software & I/O Modules |

Variable speed and pressure during stroke |

|

Production Scale |

Prototypes to Large Quantities |

Fast-turnaround samples and mass production |

Material Versatility and Customization

The breadth of materials and shapes we can produce is one of the widest in the industry. As a custom metal processing shop, we can manufacture almost any precision metal parts you need. We also support more than 30 metal materials including stainless steel, aluminum alloy, copper alloy, and various specialty grades. Each material behaves differently under the pressure of a continuous automatic punch press, requiring specific lubrication and die clearances.

Our employees have many years of experience in planning and assisting in the design of manufacturable parts. This consultative approach is critical during the prototyping phase. From prototypes to large quantities, our deep drawing design and production team provides fast-turnaround samples and high-quality finished products on specification, on time, and on budget. By analyzing the grain structure and tensile strength of the selected alloy, our team ensures that the chosen stamping process—whether flanging, punching, or deep drawing—is optimized for the material's specific characteristics.

Engineering Excellence and Design Assistance

A successful stamping project begins long before the first coil is loaded into the continuous automatic punch press. High-precision stamping manufacturers must bridge the gap between theoretical design and physical manufacturability. Our engineering team works closely with clients to refine part geometries, ensuring that sharp corners are radiused and hole placements are optimized for the progressive die layout.

This collaborative planning significantly reduces the risk of die failure and material waste. By utilizing advanced simulation software, we can predict how a metal sheet will flow through the die stations, allowing us to identify potential stress points before the expensive tool-making process begins. This proactive engineering ensures that even the most complex micro-hole arrays or multi-curved surfaces are produced with absolute fidelity to the original CAD model.

High-Volume Efficiency and Unit Cost Reduction

The primary economic advantage of a continuous automatic punch press is the drastic reduction in unit costs associated with large-scale production. When a facility can achieve a single-day production capacity of 100,000 pieces, the overhead of setup and tooling is distributed across a massive volume, providing significant savings to the client.

Furthermore, the automation inherent in our stamping processes reduces the need for secondary manual operations. Features such as tapping, de-burring, and cleaning can often be integrated directly into the progressive die sequence. For high-precision stamping manufacturers, this integrated approach is the key to delivering high-quality finished products on budget. Whether providing components for the aerospace sector or high-volume consumer electronics, our facility's commitment to continuous investment in technology ensures we remain at the forefront of the precision metal processing industry.

Eng

Eng  中文简体

中文简体