How does the quality of Stamping Metal Parts impact the overall durability and performance of the final product in a manufacturing process?

2025.05.16

2025.05.16

Industry News

Industry News

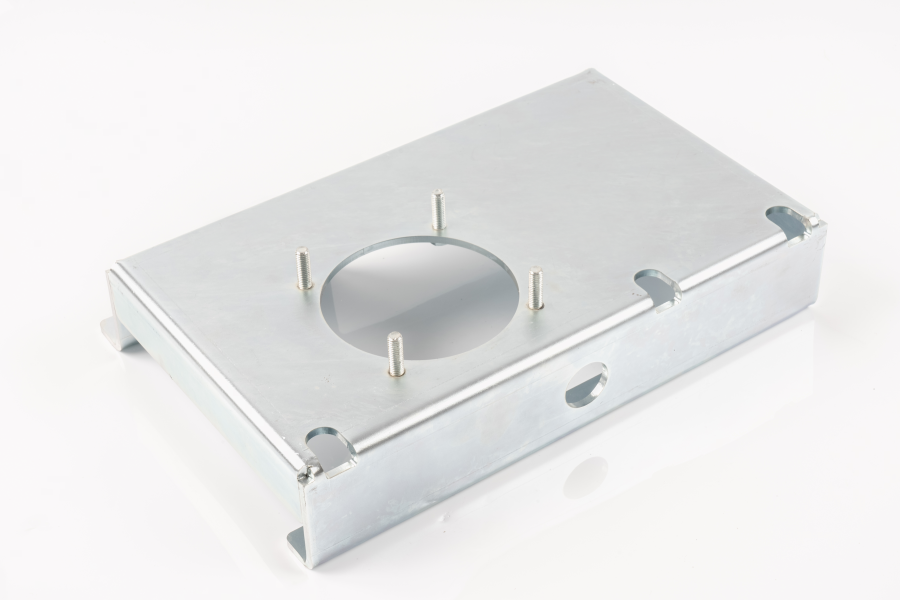

High-quality Stamping Metal Parts ensure that the final product maintains structural integrity under operational stresses. Parts that are stamped with precision, using high-quality materials and processes, will exhibit uniform thickness, strength, and durability. If the parts are poorly stamped, there may be weaknesses such as inconsistent thickness, internal voids, or cracks, all of which can compromise the part’s strength. This could lead to premature failure, bending, or breaking during use, especially in applications requiring high mechanical stress. In contrast, well-manufactured parts ensure that the final product can withstand both static and dynamic loads without experiencing distortion, cracks, or deformation.

The precision of Stamping Metal Parts directly impacts the fit and assembly of the final product. High-quality parts will meet the tight tolerances specified in the design phase, ensuring that components fit together perfectly during assembly. Poorly stamped parts with dimensional inaccuracies can result in poor assembly, misalignments, or gaps in the final product, which could compromise its overall performance. This can be particularly problematic in industries such as automotive, aerospace, or electronics, where tight tolerances are critical for safety, performance, and efficiency. The more precise the stamping process, the less time and effort will be required during the assembly process to adjust or correct parts, reducing potential delays and quality control issues.

The surface finish of Stamping Metal Parts is an important factor in both the visual appeal and the functional performance of the final product. High-quality stamped parts will exhibit smooth, consistent surfaces with minimal burrs, scratches, or defects. These surface finishes are essential not only for aesthetics but also for the functionality of the part. For example, parts with rough or uneven surfaces can create friction, wear, or corrosion during operation, leading to reduced performance and lifespan. In some cases, poor surface finishes may also require additional post-processing steps, such as grinding or polishing, to correct the issues, which increases production costs and time.

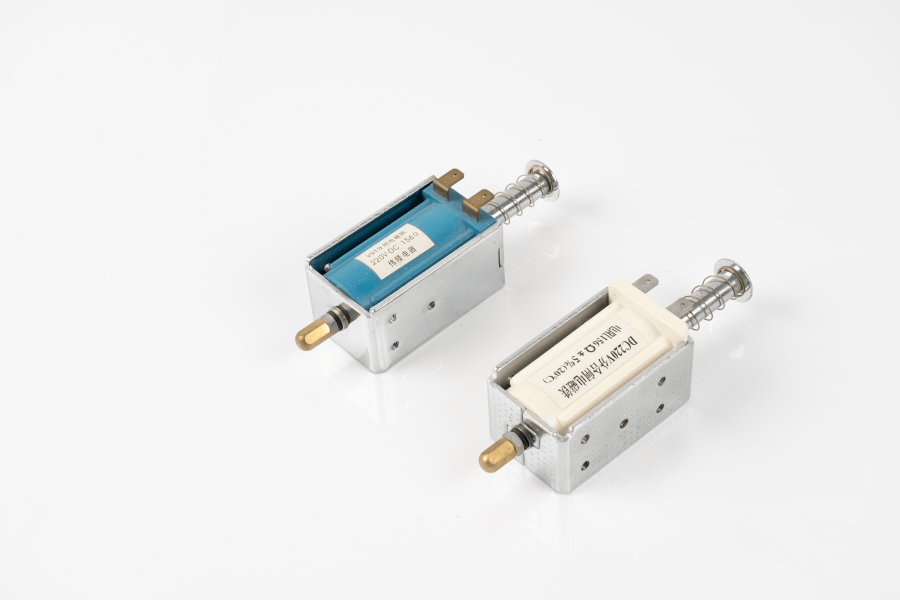

The quality of the raw material used in the stamping process has a significant effect on the final product’s durability. High-quality materials, such as high-grade steel or aluminum, provide greater strength, resistance to wear, and protection against corrosion. If the material quality is subpar, the stamped parts may be prone to defects like cracks, fractures, or material degradation over time. For example, using low-quality steel might lead to premature fatigue or brittleness, affecting the lifespan of the component. Consistent material quality ensures that the part performs reliably across its expected service life and under varying conditions of use.

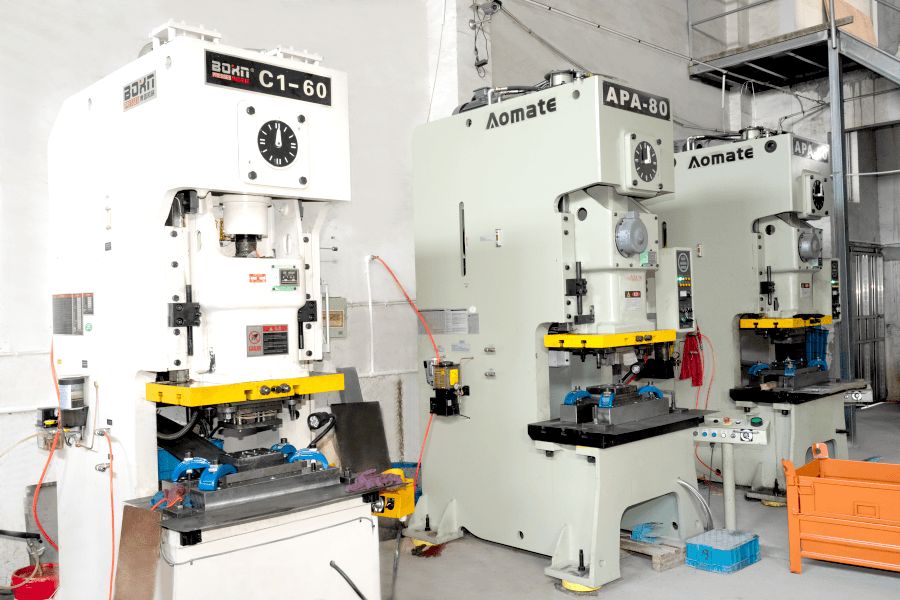

In mass production, consistency in the quality of Stamping Metal Parts is essential for maintaining the reliability of the final product. Parts produced in multiple batches must adhere to the same specifications, with no variation in material properties, dimensions, or finishing quality. Variability in part quality can cause discrepancies in product performance, leading to defects or failures when the final product is assembled. For example, inconsistent stamping processes could lead to some parts being stronger or more durable than others, resulting in uneven performance in the final product, potentially leading to failures or the need for costly rework or replacements.

Durability and long-term performance are heavily influenced by the quality of Stamping Metal Parts, particularly in applications subject to cyclical stresses or fatigue. High-quality parts with uniform thickness and consistent material properties are less likely to fail under repeated stress or vibration. Poorly stamped parts with weak spots, improper grain structure, or internal flaws are more susceptible to fatigue failure over time, which can significantly reduce the lifespan of the final product. Ensuring that each part is produced with the highest quality materials and processes helps to mitigate the risk of fatigue and guarantees that the product remains reliable over its expected lifespan.

Eng

Eng  中文简体

中文简体