Why are sheet metal parts so important in modern manufacturing?

2025.07.22

2025.07.22

Industry News

Industry News

What are sheet metal parts?

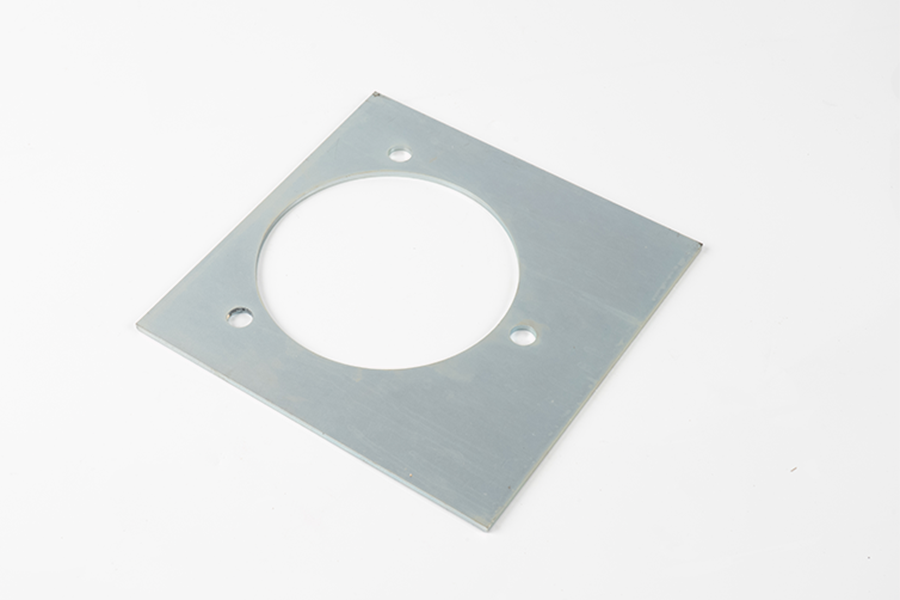

Sheet metal parts are metal components with specific structures and functions formed by shearing, stamping, bending, welding, and surface treatment of metal sheets. Its thickness is usually between 0.2mm and 6mm, and can be processed into complex shells, brackets, chassis, housing and other shapes according to requirements.

The three basic steps of sheet metal processing are:

Cutting:

Cutting is the first core link in the sheet metal processing process. Its main purpose is to initially cut large-sized metal sheets according to the size and shape of the product design drawings, thereby providing accurate raw materials for subsequent bending and assembly. Modern sheet metal manufacturing companies usually use high-precision equipment for cutting, such as laser cutting machines, waterjet cutting machines and CNC punching machines.

Laser cutting: Use a high-energy laser beam to quickly melt metal, which can achieve extremely high cutting accuracy, and is suitable for parts processing with complex graphics and high-detail requirements.

Waterjet cutting: Rely on high-pressure water flow mixed abrasive for cold cutting, suitable for materials with strict control requirements for heat-affected zones, such as stainless steel, aluminum alloy, etc.

CNC punching machine: It is molded by mold stamping and suitable for medium and large-scale production, fast speed and low cost.

Cutting accuracy not only affects the appearance of the product, but also directly affects whether the assembly is smooth and is the basic link of the entire sheet metal processing process.

Bend:

Bending is a key step in deforming the metal sheet after the cutting is completed. By bending, the flat metal plate can form various angles and geometric shapes according to the design requirements, thus becoming a three-dimensional structural part. This process is usually done with a CNC Press Brake and a matching mold.

CNC bending machine: The bending angle and position can be accurately controlled according to the preset program to ensure the consistency of batch product dimensions.

Mold selection: It is an important factor affecting the bending quality. It needs to be matched according to the type of material, thickness and bending radius to prevent the occurrence of defects such as cracks and rebound.

Bending not only changes the spatial structure of the metal plate, but also is an important means to realize functions. For example, forming structural features such as reinforcement ribs, slots, and frames, is a key step in realizing product strength and assembly structure.

Assembly:

Assembly is the last step in the sheet metal processing process. It mainly integrates the cut and bent sheet metal parts into a complete component or equipment shell through a variety of connections. This process not only tests technical accuracy, but also requires rigor and consistency of operation. Common connection methods include welding, riveting, threaded connection and bonding.

Welding: is one of the most commonly used connection methods and is suitable for scenarios where high-strength connection is required, such as steel structural parts, cabinet frames, etc. Commonly used equipment include argon arc welding machines, carbon dioxide gas welding machines, etc.

Riveting: It is suitable for metal connection occasions that are not suitable for high temperature treatment. It is widely used in the aviation and automobile fields, and has the characteristics of light structure and high strength.

Threaded connection: It is suitable for structural parts that need to be disassembled and assembled repeatedly, making it easier to repair and upgrade later.

Industrial bonding: Can be used for connection between composite materials or surface treatment parts to avoid thermal deformation of metal and improve appearance integrity.

The high-quality assembly process not only ensures the overall strength and functional realization of the sheet metal structure, but also determines the stability and safety of the use of the final product, and is the "last mile" of product molding.

The main advantages of sheet metal processing technology

Strong flexibility and high customization capability: The sheet metal process does not rely on expensive mold systems, and is suitable for customized production in small and medium batches of multiple varieties. It is especially suitable for industries with diverse needs such as non-standard equipment, electronic chassis, electrical cabinets, etc.

High forming accuracy and good repeatability: With the help of CNC technology and three-dimensional CAD drawings, sheet metal parts can achieve micron-level precision machining to ensure high consistency in each batch of products.

Fast processing speed and short delivery cycle: laser cutting and automated bending technology greatly improves processing efficiency and meets the high requirements for fast delivery in today's market.

Lightweight structure and reliable strength: while achieving lightweight structure, sheet metal parts still have good mechanical strength and impact resistance, making them ideal components for a variety of high-performance equipment.

Wide range of applications, supporting the development of multiple industries

Sheet metal parts penetrate almost all manufacturing industries and are the "invisible skeleton" that supports industrial operation. Its typical applications are as follows:

| Industry | Typical Sheet Metal Products | Performance Requirements |

|---|---|---|

| Automotive | Body structural parts, chassis brackets, engine shields | High strength, corrosion resistance, compliant with crash safety standards |

| Aerospace | Fuselage skins, instrument panels, interior brackets | Lightweight, high temperature resistance, high precision |

| Telecommunications & Electronics | Server enclosures, distribution boxes, electrical control cabinets, racks | Excellent heat dissipation, effective electromagnetic shielding, high machining accuracy |

| Construction & Architecture | Elevator decorative panels, building façade cladding, curtain wall frameworks | Aesthetic appearance, wind and pressure resistance, corrosion resistance |

| Medical Equipment | Medical device enclosures, equipment stands, stainless steel trolleys | Hygienic and sterile, no sharp edges, compliant with FDA/CE standards |

Core processing equipment and process technology of sheet metal parts

High-quality sheet metal parts are inseparable from advanced processing equipment and mature manufacturing processes:

Laser cutting machine: realizes contactless fast cutting, smooth edges without subsequent polishing;

CNC bending machine: Complete accurate bending according to preset angles without damaging the metal surface;

Welding robot: efficiently complete various welding methods such as TIG/MIG/spot welding, and uniform welds;

CNC punching machine: punching, stretching, forming and other treatments on the plate;

Surface treatment lines such as powder spraying/electrophoresis/anodization: improve surface aesthetics, corrosion resistance and service life.

Eng

Eng  中文简体

中文简体