The Core Advantages of Stamping Metal Parts for Large-Scale Production

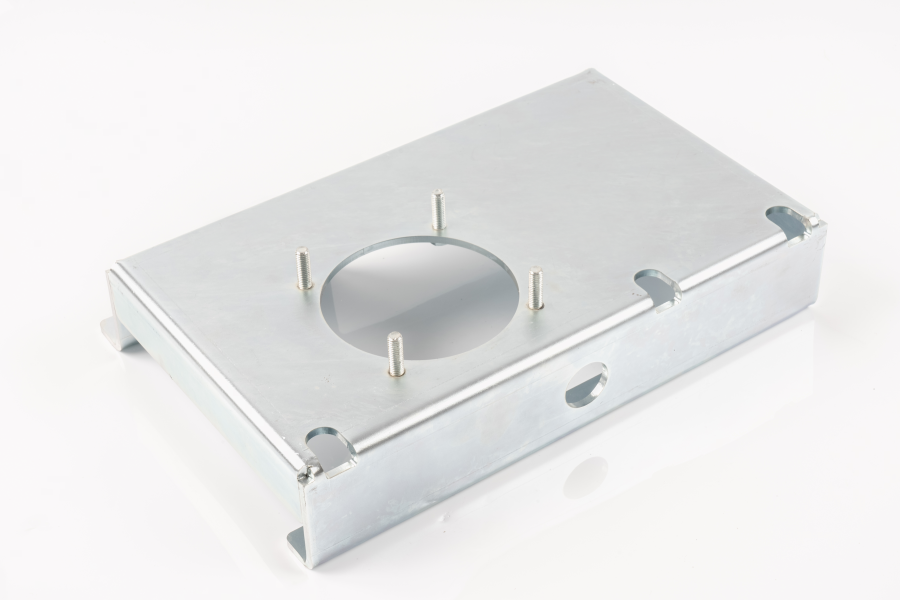

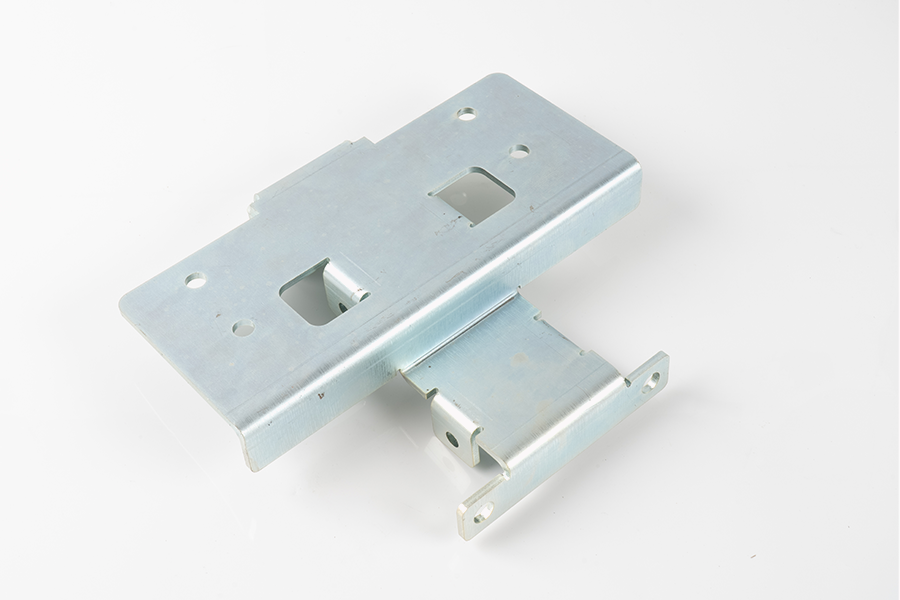

At its core, metal stamping involves shaping flat metal sheets into predefined forms using specialized dies and presses, and this process unlocks a host of benefits that set stamping metal parts apart from alternative fabrication techniques like machining or casting. The most notable advantage is its suitability for high-volume production. Unlike machining, which removes material to create a part and often requires multiple steps for complex shapes, metal stamping can produce hundreds or even thousands of identical components in a single production run with minimal variation. This consistency is a game-changer for industries that rely on standardized parts, such as the automotive sector, where a single vehicle may require dozens of stamping metal parts for its chassis, engine components, and interior fittings.

Cost efficiency is another defining feature of stamping metal parts. The initial investment in custom dies may seem substantial, but for large production batches, the per-unit cost plummets dramatically compared to other methods. This is because the stamping process minimizes material waste—flat metal sheets are cut and formed with precision, leaving little scrap behind—while also reducing labor costs through automation. Modern stamping facilities often integrate robotic systems to feed metal sheets into presses, remove finished parts, and inspect for defects, further driving down operational expenses. For manufacturers scaling up production to meet market demand, stamping metal parts offer a pathway to lower costs without sacrificing quality.

Precision and Durability: Non-Negotiable Traits of Stamping Metal Parts

In industries where component failure can have catastrophic consequences—such as aerospace or medical device manufacturing—precision and durability are non-negotiable. Stamping metal parts excel in both areas, thanks to advanced die design and high-pressure forming processes. The dies used in metal stamping are engineered with micrometer-level accuracy, ensuring that every part meets exact specifications for dimensions, tolerances, and surface finish. This level of precision is critical for applications like aerospace fasteners or medical instrument components, where even the smallest deviation can compromise safety and functionality.

The durability of stamping metal parts is equally impressive. The stamping process compresses the metal’s molecular structure, enhancing its strength and resistance to wear and tear compared to cast or machined alternatives. For example, stamping metal parts used in heavy machinery are able to withstand extreme temperatures, high pressure, and repeated mechanical stress without deforming or failing. This longevity translates to lower replacement costs for manufacturers and higher reliability for end-users, making stamping metal parts a preferred choice for critical infrastructure projects, from bridge supports to power generation equipment.

Versatility of Stamping Metal Parts Across Diverse Industries

One of the key reasons stamping metal parts have become ubiquitous in manufacturing is their remarkable versatility. The process can be adapted to work with a wide range of metals, including steel, aluminum, copper, brass, and even specialty alloys. This flexibility allows manufacturers to select the ideal material for their specific application, whether it’s lightweight aluminum for aerospace components, corrosion-resistant stainless steel for marine equipment, or conductive copper for electronic connectors.

Across industries, stamping metal parts play pivotal roles:

Automotive: From brake components and door hinges to fuel system parts, stamping metal parts make up a significant portion of a vehicle’s structure and functionality, enabling automakers to meet strict safety standards while keeping production costs low.

Consumer Electronics: The compact, precise components in smartphones, laptops, and home appliances—such as battery contacts, chassis frames, and button assemblies—are often produced via metal stamping, as the process can create intricate shapes at scale.

Construction: Stamping metal parts like brackets, fasteners, and roofing components are essential for building sturdy, weather-resistant structures, with the process allowing for customization to fit unique architectural designs.

Medical Devices: Surgical instruments, implant components, and diagnostic equipment parts rely on the sterile, high-precision nature of stamping metal parts to ensure patient safety and regulatory compliance.

Addressing Common Misconceptions About Stamping Metal Parts

Despite their widespread use, stamping metal parts are not without their misconceptions, which can deter some manufacturers from leveraging their benefits. One common myth is that metal stamping is only suitable for simple, flat parts and cannot handle complex geometries. In reality, advancements in die technology—such as progressive dies and deep drawing techniques—have expanded the capabilities of metal stamping to produce highly complex, three-dimensional components. Progressive dies, for instance, allow multiple operations (cutting, bending, punching, and forming) to be completed in a single pass through the press, enabling the creation of intricate parts that once required multiple fabrication steps.

Another misconception is that stamping metal parts lack the customization needed for low-volume or prototype production. While metal stamping is indeed optimized for large batches, many stamping facilities now offer short-run and prototype services using modular die systems. These systems allow for quick die changes and adjustments, making it feasible for manufacturers to produce small quantities of custom stamping metal parts for product testing or niche applications. This adaptability has helped metal stamping remain relevant even for businesses with variable production needs.

Sustainability Benefits of Stamping Metal Parts in Modern Manufacturing

In an era where sustainability is a top priority for consumers and regulators alike, stamping metal parts offer notable eco-friendly advantages. As mentioned earlier, the stamping process generates minimal material waste compared to machining, which can discard up to 70% of the original metal stock as scrap. The scrap that is produced from stamping is also highly recyclable, with most metal stamping facilities partnering with recycling firms to repurpose leftover material, reducing reliance on virgin metal ore and lowering the carbon footprint of production.

Additionally, the energy efficiency of modern stamping presses has improved significantly in recent years. Newer models use servo-driven technology that consumes less electricity than traditional hydraulic presses, cutting down on energy costs and greenhouse gas emissions. For manufacturers aiming to achieve carbon-neutral operations or meet sustainability certifications, stamping metal parts provide a way to reduce their environmental impact while maintaining production efficiency.

As industrial manufacturing continues to evolve amid technological advancements and market pressures, stamping metal parts have proven to be far more than a basic fabrication solution—they are a strategic asset for businesses seeking to balance cost, precision, durability, and sustainability. Their ability to scale to high production volumes, adapt to diverse materials and industries, and deliver consistent quality makes them an indispensable component in the global supply chain.

The question of whether stamping metal parts are the most cost-effective solution for industrial manufacturing can be answered with a definitive yes, particularly for businesses that prioritize scalability and long-term value. From automotive assembly lines to medical device labs, stamping metal parts continue to drive innovation and efficiency, solidifying their position as a cornerstone of modern manufacturing for years to come.

2025.12.04

2025.12.04

Industry News

Industry News

Eng

Eng  中文简体

中文简体