Why Are Stamping Metal Parts Becoming the Backbone of Modern Manufacturing and Industrial Production?

2025.12.11

2025.12.11

Industry News

Industry News

Understanding Stamping Metal Parts and the Production Process

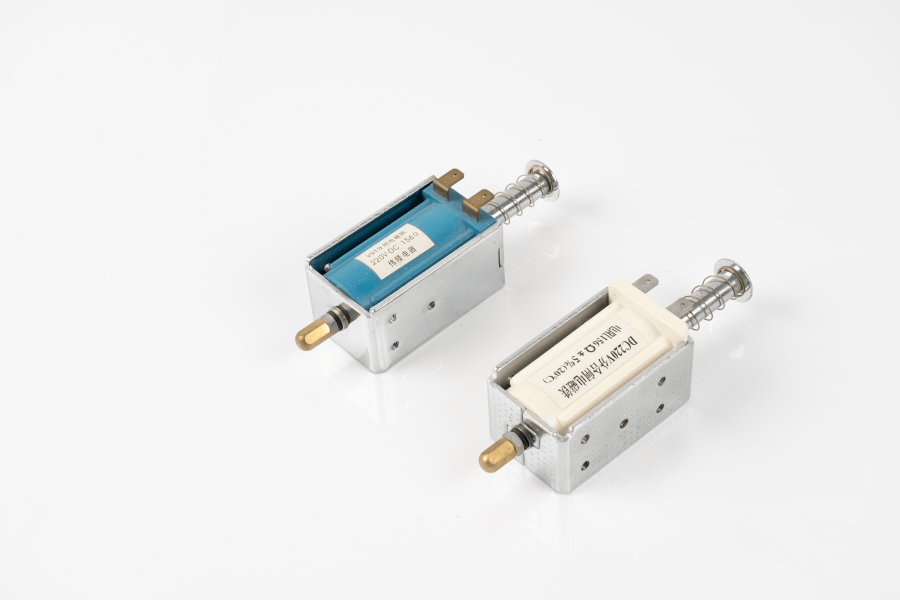

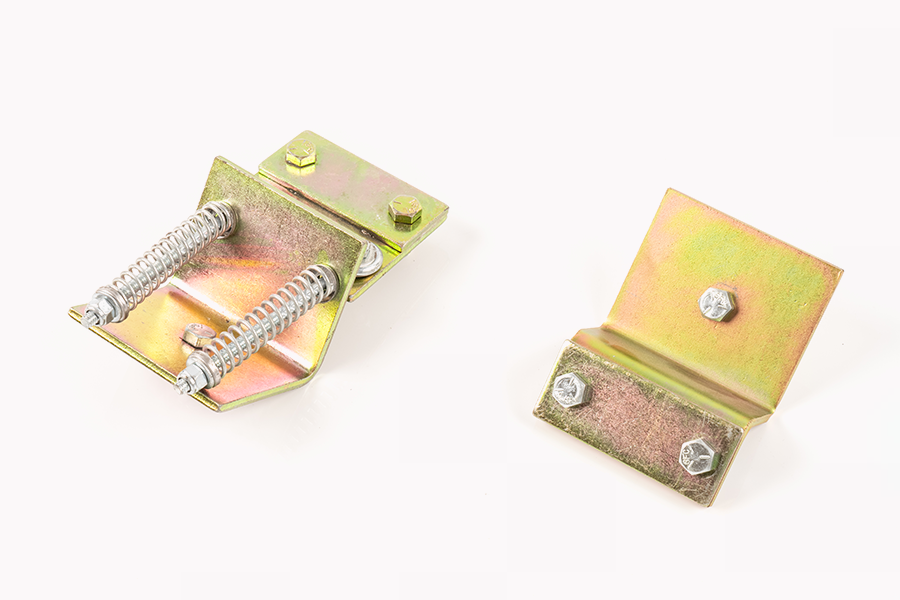

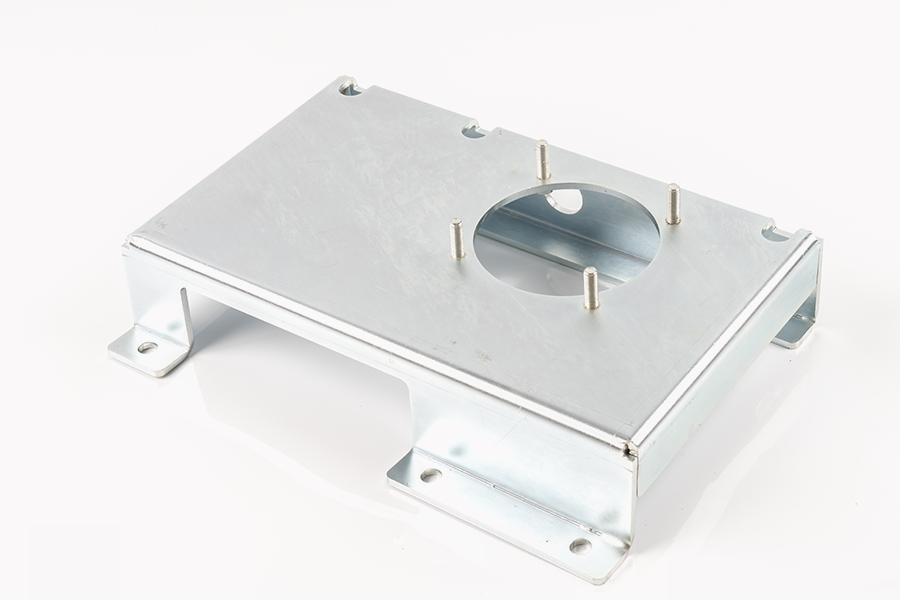

Stamping Metal Parts are components produced through a metal forming process that uses dies and presses to cut, bend, shape, or emboss metal sheets into specific forms. This process typically involves placing a metal sheet—such as steel, aluminum, copper, or brass—into a stamping press where a tool and die surface form the metal into the desired shape.

The stamping process can include several operations, such as blanking, punching, bending, coining, and drawing. These techniques allow manufacturers to produce complex and precise metal parts efficiently and repeatedly, making stamping metal parts ideal for mass production.

High Precision and Consistent Quality

One of the primary advantages of Stamping Metal Parts is their high level of precision and consistency. Once a stamping die is designed and set up, it can produce thousands or even millions of identical parts with minimal variation. This level of consistency is critical in industries where tight tolerances and exact specifications are required.

Automotive manufacturers, for example, depend heavily on stamping metal parts for structural components, brackets, and enclosures. Precision stamping ensures that each part fits perfectly into the final assembly, improving safety, performance, and reliability.

Cost-Effective for High-Volume Production

Stamping Metal Parts offer significant cost advantages, particularly for large-scale production. While the initial investment in tooling and dies can be substantial, the cost per unit decreases dramatically as production volume increases. This makes metal stamping one of the most cost-effective manufacturing methods for producing high quantities of metal components.

In addition, stamping processes are highly automated, reducing labor costs and minimizing material waste. Efficient material usage not only lowers production expenses but also supports more sustainable manufacturing practices.

Versatility Across Multiple Industries

The versatility of Stamping Metal Parts is another reason for their widespread adoption. They are used in a wide range of industries, including:

Automotive and transportation;

Electronics and electrical equipment;

Construction and infrastructure;

Home appliances and consumer goods;

Medical devices and industrial machinery.

From small electronic connectors to large structural panels, stamping metal parts can be customized to meet diverse functional and design requirements.

Wide Range of Materials and Finishes

Stamping Metal Parts can be produced using various materials, such as carbon steel, stainless steel, aluminum, copper, and specialty alloys. This flexibility allows manufacturers to select materials based on strength, corrosion resistance, conductivity, or weight considerations.

Additionally, stamped metal parts can undergo secondary processes such as plating, coating, polishing, or heat treatment. These finishes enhance durability, appearance, and performance, ensuring the parts meet both functional and aesthetic requirements.

Supporting Advanced Manufacturing Technologies

As manufacturing evolves, Stamping Metal Parts continue to adapt to new technologies. Modern stamping presses are equipped with advanced control systems, sensors, and automation features that improve accuracy and efficiency. Progressive dies and transfer stamping techniques allow for complex multi-step forming processes within a single production cycle.

This integration with smart manufacturing systems supports real-time monitoring, quality control, and predictive maintenance, further enhancing productivity and reducing downtime.

Strength, Durability, and Structural Integrity

Metal stamping produces parts with excellent strength and durability. The forming process can enhance the mechanical properties of the metal, resulting in components that are strong yet lightweight. This is particularly important in industries such as automotive and aerospace, where reducing weight without compromising strength is a key objective.

Stamping Metal Parts are designed to withstand mechanical stress, vibration, and environmental exposure, making them reliable components in demanding applications.

Environmental and Sustainability Benefits

Sustainability is becoming a major focus in industrial production, and Stamping Metal Parts contribute positively in this area. The process generates minimal waste, as excess material can often be recycled. High production efficiency also reduces energy consumption per unit, supporting environmentally responsible manufacturing.

By using recyclable metals and optimizing production processes, manufacturers can reduce their environmental footprint while maintaining high output levels.

Meeting the Demands of Global Markets

As global markets expand and competition intensifies, manufacturers must deliver high-quality products quickly and consistently. Stamping Metal Parts enable companies to meet these demands by offering scalable production, fast turnaround times, and reliable quality.

From custom prototypes to large-volume orders, metal stamping provides the flexibility needed to adapt to changing market requirements and customer expectations.

Stamping Metal Parts have become a cornerstone of modern manufacturing due to their precision, efficiency, and versatility. By enabling high-volume production with consistent quality, metal stamping supports the needs of diverse industries and complex product designs.

As technology continues to advance and sustainability becomes increasingly important, stamping metal parts will remain a key manufacturing solution. Their ability to combine cost-effectiveness, durability, and adaptability ensures they will continue to play a vital role in shaping the future of industrial production worldwide.

Eng

Eng  中文简体

中文简体