Can Advanced Progressive Die Technology Deliver Near-Zero Tolerance in High-Volume Metal Stamping?

2025.12.17

2025.12.17

Industry News

Industry News

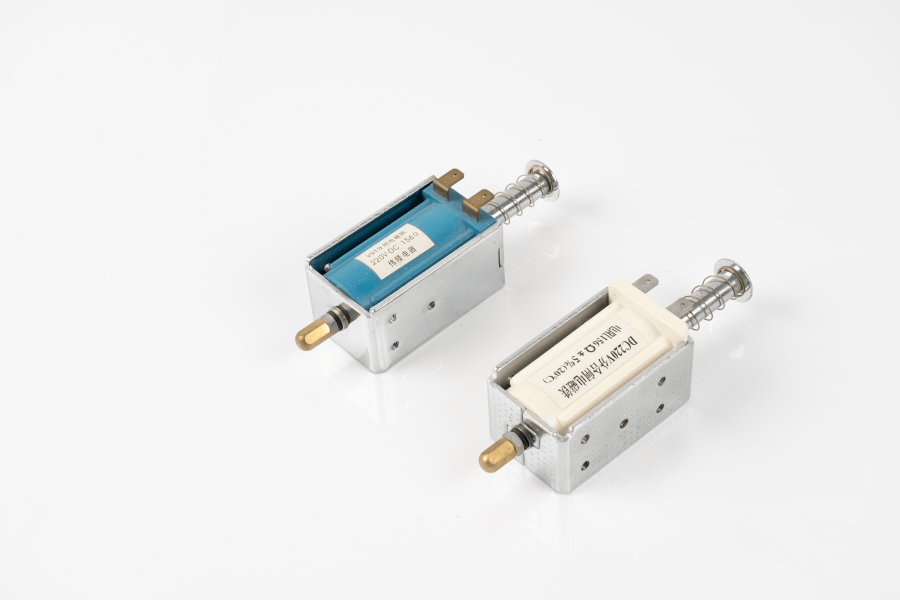

A custom metal processing shop has unveiled a technical deep dive into its proprietary and expansive capabilities in High Precision Stamping, emphasizing a synthesis of cutting-edge die technology, advanced press controls, and unparalleled material versatility. The core mission is to provide intricate precision metal stampings with exceptionally high accuracy, repeatability, and cost efficiency, regardless of production volume, from prototypes to mass production. This detailed review focuses purely on the applied engineering principles and operational architecture that enable this industry-leading performance.

The Triad of Die Technology: Mastering Complexity and Volume

The foundation of the firm's precision capability rests on the strategic deployment of three distinct die technologies: the multi-station progressive die, the standard progressive die, and the single punch die.

Multi-Station Progressive Die Technology: This is the flagship process used for the highest volume and most intricate components. In this setup, a single strip of metal stock is fed automatically through a sequence of stations, with each station performing one or more simultaneous operations—be it punching, bending, or shallow drawing. The key technical advantage is the complete integration and chaining of operations, which inherently minimizes part handling, eliminates cumulative error, and drastically accelerates the cycle time. The resulting parts exhibit excellent accuracy and are produced at speeds that contribute directly to the achieved single-day production capacity of up to 100,000 pieces, which is a primary driver in reducing unit costs for complex stampings.

Standard Progressive Die: Used for high-volume parts with slightly less complexity or materials requiring specialized handling at each stage. It still relies on continuous strip feeding but offers design flexibility for operations that might require more space or different mechanical action between stages.

Single Punch Die Technology: Reserved primarily for prototyping, low-volume specialist components, or parts requiring a single, highly controlled high-tonnage operation (such as final sizing or blanking). This ensures that even initial development and short runs meet the same stringent tolerance standards applied to mass-produced items.

Precision Engineering: Shaping Complex Geometries

These technologies facilitate a range of highly specialized forming processes capable of creating precision structures previously considered difficult, if not impossible, to achieve through traditional methods.

Key forming capabilities include:

Deep Drawing: This is a core competency, allowing the creation of complex, seamless structures where the depth of the finished part exceeds its diameter. This process demands extremely precise control over the material flow, tension, and pressure to prevent wrinkling, tearing, or inconsistent wall thickness. The firm’s expertise in this area allows for the production of the most complex deep-drawn stampings with consistently tight tolerances and perfect repeatability from the very first piece to the last.

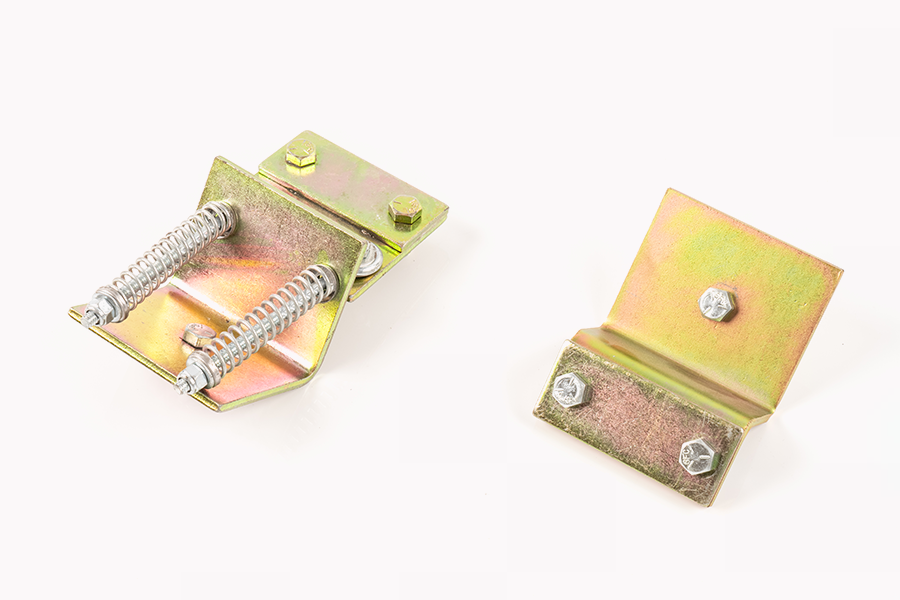

Flanging: The process of bending the material edge to form a lip, often used for structural reinforcement or to create joining surfaces.

Punching and Blanking: Used to create precise micro-hole arrays and intricate external contours, where the alignment and burr control are paramount for final assembly quality.

Multi-Curved Surfaces: The combined process control enables the formation of components featuring non-uniform, multi-axis curves, often required in modern, compacted product designs.

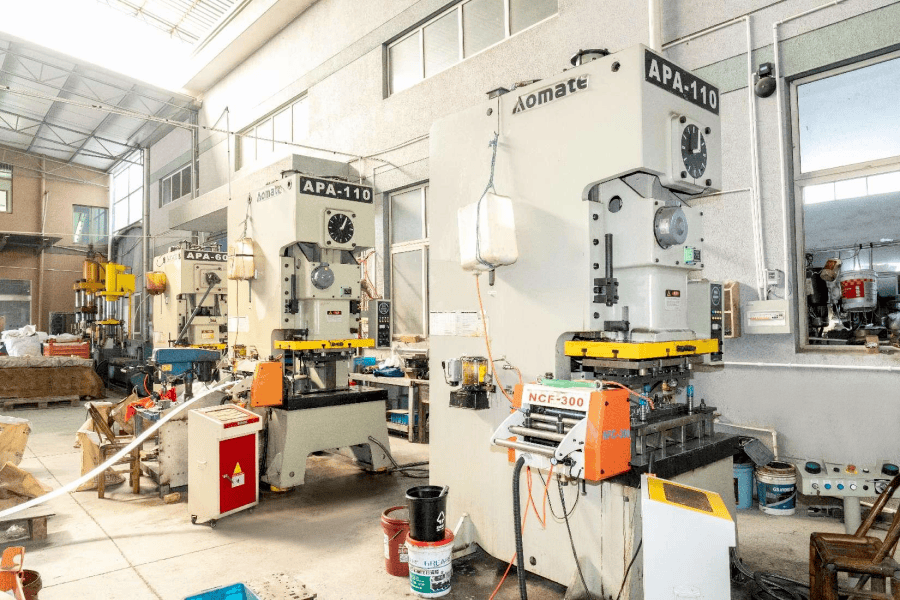

Technological Infrastructure: Presses and Controls

To execute these high-precision processes, the company relies on a robust investment in both mechanical and hydraulic press technology, critically paired with sophisticated control systems.

The investment includes a range of large-tonnage presses equipped with advanced control modules. These controls incorporate sophisticated software, high-speed sensors, I/O modules, and variable drives. This combination allows engineers to dynamically control the speed and pressure applied by the die throughout the entire forming stroke, not just at the endpoints. This real-time, fine-tuned control is transformative for deep drawing and complex forming, allowing for calculated manipulation of material flow to compensate for variables like material spring-back or thinning.

This integration of advanced software with robust mechanical systems allows the manufacturing floor to maintain industry-leading complex deep drawing capabilities, setting a high bar for the achievable complexity and dimensional accuracy in the finished parts.

Internal Tooling and Material Versatility

A critical factor underpinning the rapid response and precision output is the presence of an in-house tool room. This capability is instrumental for several reasons:

Design Iteration and Speed: Tools can be designed, fabricated, and tested internally, dramatically speeding up the turnaround time for prototypes and samples.

Immediate Maintenance and Modification: Any necessary adjustments to dies to maintain tight tolerances during long production runs can be made immediately, preventing scrap and ensuring continuous quality.

manufacturability Consulting:The in-house tool room staff collaborates closely with experienced employees who have significant expertise in planning and assisting in the design of manufacturable parts, ensuring that designs are optimized for the stamping process before tooling even begins.

The operational flexibility is further defined by the breadth of materials supported. The capacity to process more than 30 metal materials is one of the widest in the industry, including but not limited to: stainless steel (various grades), aluminum alloy, copper alloy, brass, bronze, and specialty steels. This versatility ensures that regardless of whether the final component requires high strength, corrosion resistance, electrical conductivity, or specific thermal properties, the optimal material can be selected and processed with high precision.

Key Capabilities

|

Area of Expertise |

Technical Specification / Achievement |

Benefit to Product |

|---|---|---|

|

Production Capacity |

Up to 100,000 pieces per day |

Significant unit cost reduction in high volume |

|

Deep Drawing |

Complex deep-drawn stampings with tight tolerances |

Allows for intricate, seamless structural components |

|

Process Control |

Dynamic speed and pressure adjustment throughout stroke |

Prevents material defects (wrinkling, tearing, thinning) |

|

Material Support |

Over 30 metal materials (Stainless Steel, Aluminum, Copper) |

Optimal material selection for specific functional requirements |

|

Quality Standard |

Perfect repeatability from first piece to last |

Guaranteed consistency and reduced inspection time |

From prototypes to massive quantity orders, the deep drawing design and production team ensures that high-quality finished products are delivered on specification, on time, and on budget. As a custom metal processing shop, the technical infrastructure and employee expertise are geared to manufacture almost any precision metal parts required by advanced industries.

Eng

Eng  中文简体

中文简体