Can Stamping Metal Parts Become the Backbone of High-Precision Manufacturing in a Fast-Evolving Industrial World?

2026.01.29

2026.01.29

Industry News

Industry News

The Rising Demand for High-Precision Stamping Metal Parts

In the era of advanced manufacturing, precision, efficiency, and scalability are no longer optional—they are fundamental requirements. Across industries such as automotive manufacturing, electronic equipment, home appliance hardware, and new energy systems, Stamping Metal Parts have become indispensable components that support structural integrity, functional reliability, and large-scale production efficiency. As global industries continue to pursue lightweight design, higher strength, and tighter tolerances, metal stamping technology is playing a more critical role than ever before.

Stamping metal parts are not just simple formed components; they are the result of a highly integrated manufacturing process that combines precision molds, advanced materials, and high-speed stamping machines. This combination enables the mass production of complex metal structures while maintaining consistent quality and millimeter-level dimensional accuracy.

What Are Stamping Metal Parts and Why Are They Essential?

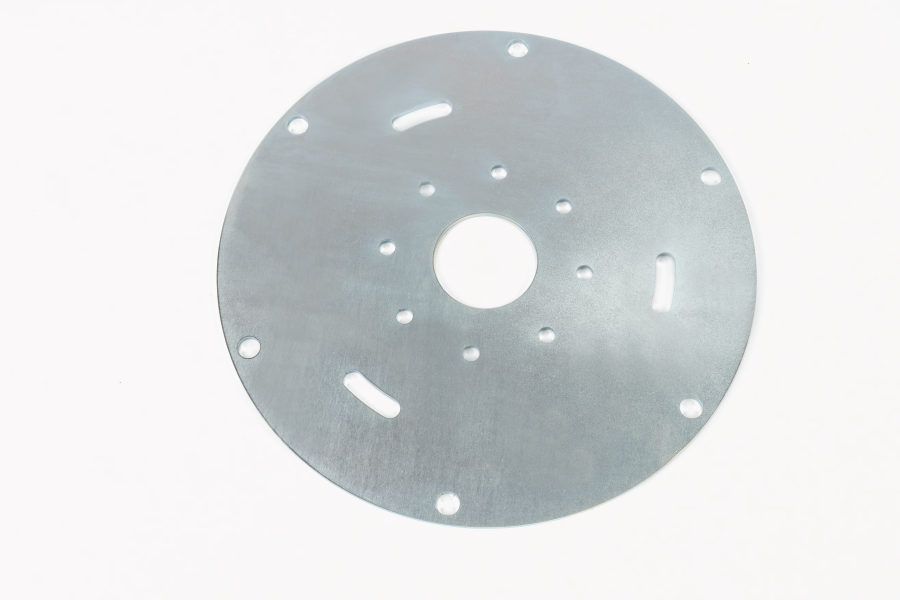

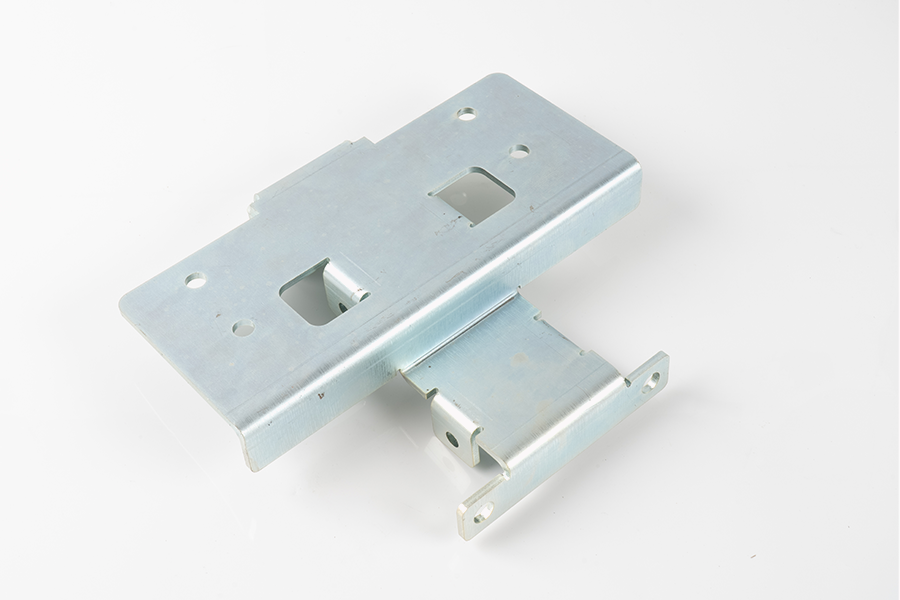

Stamping Metal Parts are formed by applying controlled pressure to metal sheets using precision dies and stamping presses. Through processes such as punching, bending, drawing, and forming, flat metal sheets are transformed into functional components with specific geometries and performance characteristics. This method is widely recognized for its ability to deliver high repeatability, tight tolerances, and excellent surface flatness.

What makes stamped metal parts particularly valuable is their suitability for high-volume production without compromising precision. Once the tooling is developed, stamping allows manufacturers to produce thousands or even millions of identical parts efficiently, making it ideal for industries that require both quality and scale.

Precision Molds and High-Speed Stamping: A Perfect Integration

At the core of modern Stamping Metal Parts production lies the seamless integration of precision molds and high-speed stamping processes. Precision molds are engineered to exact specifications, ensuring that each stamped part conforms to design requirements down to the millimeter. High-speed stamping machines then execute these designs with remarkable consistency, even under demanding production schedules.

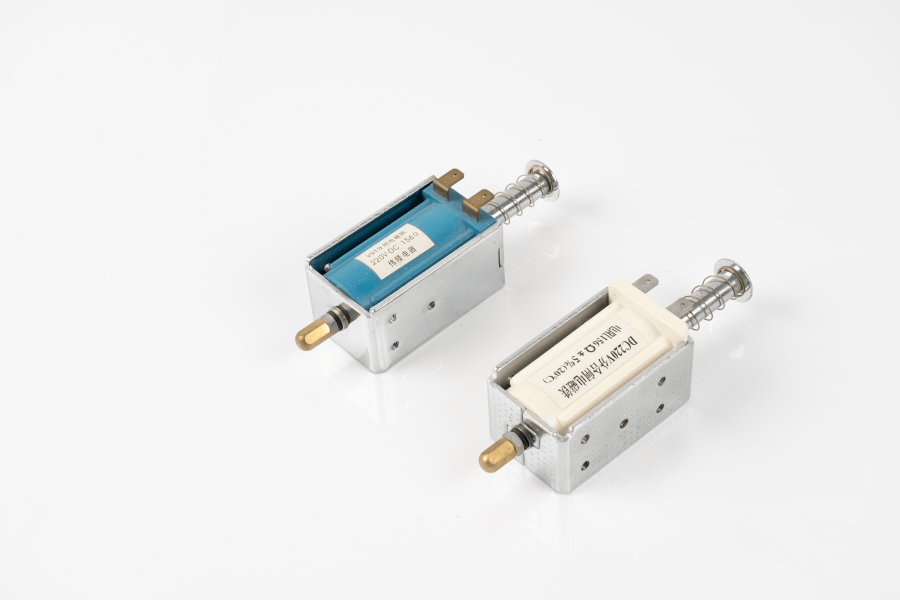

This integration allows manufacturers to shape complex structures that would be difficult or costly to produce using other manufacturing methods. From intricate connectors used in electronic devices to robust motor housings in new energy equipment, stamping technology offers unmatched versatility.

Key Performance Dimensions of Stamping Metal Parts

The performance of Stamping Metal Parts is measured across several critical dimensions, each of which contributes to their suitability for demanding applications.

First is millimeter-level dimensional accuracy. Tight tolerances ensure that stamped parts fit seamlessly into assemblies, reducing the need for secondary machining or adjustments. This is particularly important in applications such as precision connectors and automotive components, where even minor deviations can affect performance.

Second is compressive and impact strength. Stamped metal parts are designed to withstand mechanical stress, making them ideal for frame reinforcements, protective housings, and load-bearing structures.

Third is surface flatness and consistency. High-quality stamping processes produce parts with smooth, uniform surfaces, which is essential for both functional performance and aesthetic requirements, especially in visible hardware components.

Applications Across Core Industrial Sectors

The versatility of Stamping Metal Parts is reflected in their widespread use across multiple industries. In automotive manufacturing, stamped components are used for body panels, brackets, frame reinforcements, and safety-critical structures. Their strength and precision contribute directly to vehicle safety and durability.

In electronic equipment, stamping metal parts are essential for shielding, connectors, housings, and structural supports. The ability to produce thin, precise components with consistent quality makes stamping ideal for electronics that demand compact design and reliable performance.

Home appliance hardware also relies heavily on stamped metal parts. From internal frames to external panels and mounting brackets, stamping ensures durability while supporting cost-effective mass production.

In the rapidly growing new energy sector, stamped metal parts play a crucial role in motor housings, battery enclosures, and structural components. Their strength, accuracy, and scalability align perfectly with the needs of renewable energy systems and electric vehicles.

Advanced Die Technologies: Single Die, Continuous Die, and Progressive Die

A major strength of modern Stamping Metal Parts manufacturing lies in the use of diverse die technologies. Single die stamping is suitable for low-volume or large, simple parts, offering flexibility and cost control during early production stages.

Continuous die stamping enables multiple operations to be performed sequentially, improving efficiency while maintaining precision. Progressive die stamping takes this a step further by integrating multiple forming processes into a single production line, allowing complex parts to be produced in one continuous operation.

These technologies ensure that manufacturers can meet a wide range of customer requirements, from simple brackets to highly complex technical stampings.

Flexibility in Size, Material, and Customization

One of the defining characteristics of professional Stamping Metal Parts production is its adaptability. With punching machines of different tonnages, manufacturers can handle metal stampings of various sizes and thicknesses. Whether the requirement is for small, intricate components or large structural parts, stamping technology provides the necessary flexibility.

Customization is another key advantage. By adjusting die design, material selection, and process parameters, stamping metal parts can be tailored to meet specific functional, mechanical, and aesthetic requirements. This makes stamping an ideal solution for OEMs and suppliers seeking customized components with consistent quality.

Speed and Turnaround: Meeting Tight Production Deadlines

In competitive industrial markets, speed is often as important as quality. Stamping Metal Parts manufacturing is well known for its fast turnaround times once tooling is in place. High-speed stamping machines can produce large volumes of parts in a short period, helping customers meet tight deadlines without sacrificing precision.

This efficiency is particularly valuable in industries such as automotive and electronics, where production schedules are tightly synchronized and delays can have significant downstream impacts.

Quality Control and Consistency in Mass Production

Consistency is a hallmark of high-quality Stamping Metal Parts. Advanced stamping processes are supported by rigorous quality control systems that monitor dimensional accuracy, surface quality, and mechanical performance throughout production.

By maintaining strict control over materials, tooling, and process parameters, manufacturers ensure that every stamped part meets the same high standards. This reliability reduces assembly issues, minimizes waste, and enhances overall production efficiency for customers.

Sustainability and Material Efficiency

Stamping metal parts is also recognized for its material efficiency. By optimizing die design and layout, material waste can be minimized, supporting more sustainable manufacturing practices. Scrap metal generated during stamping can often be recycled, further reducing environmental impact.

As industries increasingly prioritize sustainability, stamping technology aligns well with goals related to resource efficiency and responsible production.

Overview of Stamping Metal Parts Capabilities

| Category | Description |

|---|---|

| Product Type | Stamping Metal Parts |

| Core Process | Precision molds + high-speed stamping |

| Accuracy Level | Millimeter-level dimensional accuracy |

| Key Strengths | High compressive and impact strength, excellent surface flatness |

| Die Technologies | Single die, continuous die, progressive die |

| Machine Range | Punching machines with multiple tonnages |

| Application Industries | Automotive, electronics, home appliances, new energy |

| Customization | Size, material, structure, and performance customization |

| Production Scale | Small batch to mass production |

Supporting Innovation in Automotive Manufacturing

As vehicles become lighter, smarter, and more energy-efficient, Stamping Metal Parts are evolving to meet new challenges. Advanced high-strength steels and aluminum alloys are increasingly used in stamping processes to reduce vehicle weight while maintaining safety and performance.

Stamped components support innovations in electric vehicles, autonomous driving systems, and advanced safety features, making them a foundational technology in modern automotive manufacturing.

Enabling Precision in Electronic and Electrical Systems

In electronics, precision and reliability are paramount. Stamping Metal Parts provide the structural backbone for many electronic systems, from connectors and terminals to shielding components that protect sensitive circuits from electromagnetic interference.

The ability to produce thin, complex shapes with tight tolerances ensures compatibility with miniaturized electronic designs, supporting ongoing innovation in consumer electronics and industrial equipment.

Meeting the Demands of the New Energy Industry

The new energy sector places unique demands on materials and components, including durability, thermal stability, and structural integrity. Stamping Metal Parts meet these demands through robust design and precise manufacturing.

Whether used in wind power systems, solar installations, or electric vehicle components, stamped metal parts contribute to the reliability and efficiency of sustainable energy solutions.

Why Stamping Metal Parts Remain a Long-Term Manufacturing Solution

Despite the emergence of new manufacturing technologies, stamping continues to hold a central position due to its unmatched combination of speed, precision, and cost-effectiveness. Stamping Metal Parts offer a proven solution that balances innovation with reliability.

Their adaptability to new materials, evolving designs, and advanced automation ensures that stamping will remain relevant as industries continue to transform.

Partnering for Precision and Performance

For customers seeking reliable, high-precision metal components, professional stamping manufacturers offer not just products but long-term partnerships. By focusing on technical stampings, advanced die technologies, and flexible production capabilities, they help customers achieve their goals efficiently and confidently.

No matter how big or small the required metal stampings, a well-equipped stamping operation can deliver with exceptional precision and speed.

Eng

Eng  中文简体

中文简体