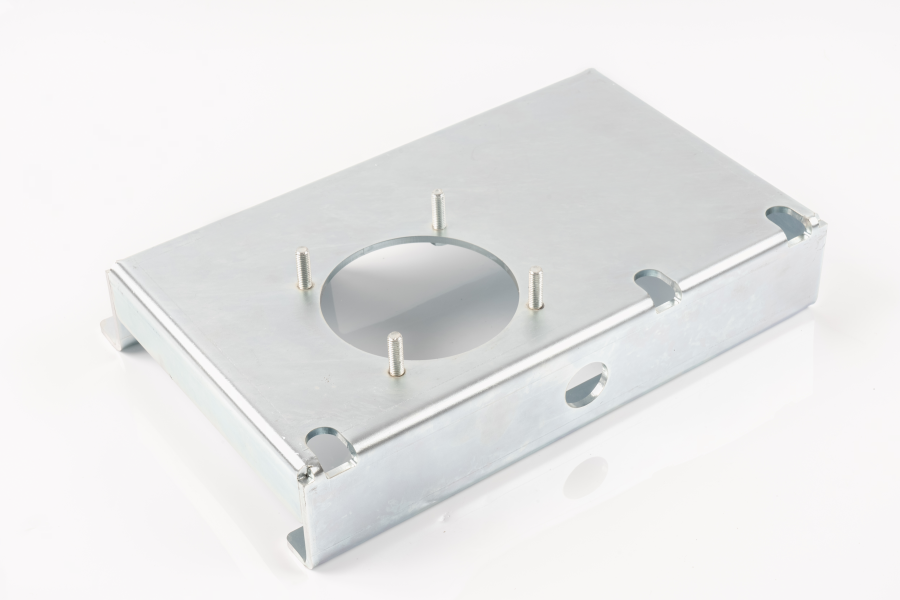

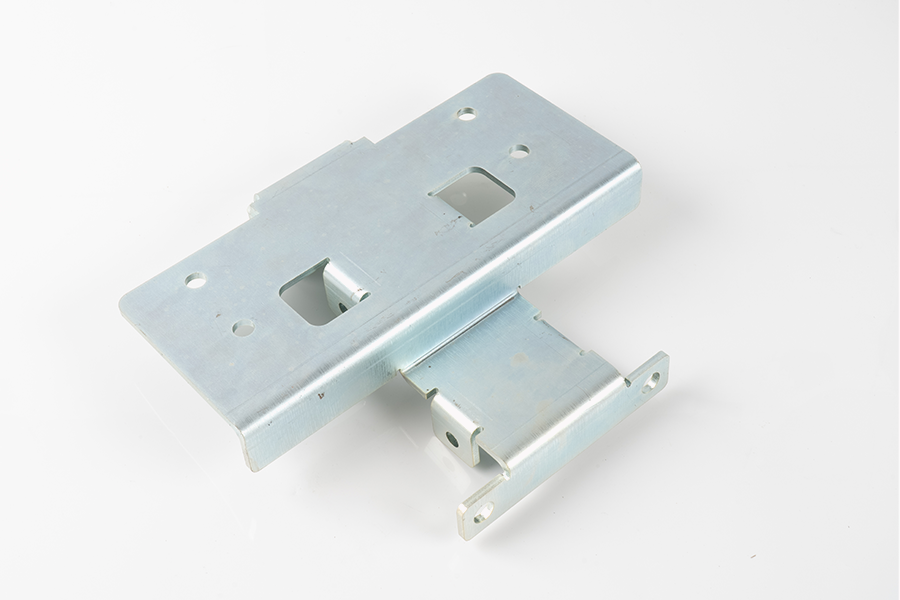

At the core of this transformation lies one essential element: Sheet Metal Parts. From automotive frames and aerospace components to electronic enclosures and architectural structures, sheet metal parts play a vital role in shaping the modern world. As industries continue to evolve, sheet metal fabrication has become one of the most versatile and indispensable manufacturing processes, enabling the production of both simple components and highly complex assemblies with exceptional accuracy.

Sheet metal fabrication is a manufacturing process that transforms flat sheets of metal into functional products through a combination of cutting, bending, and assembly techniques. This process allows manufacturers to meet diverse design requirements while maintaining tight tolerances and consistent quality. With advancements in digital design, automation, and precision machinery, sheet metal parts are now produced faster, more accurately, and more efficiently than ever before.

The growing demand for customized solutions has further elevated the importance of professional sheet metal fabrication services. From laser cutting to welding, comprehensive fabrication capabilities ensure that every project meets exact specifications, performance requirements, and delivery timelines.

Sheet metal parts are widely used because of their adaptability to different materials, shapes, and applications. Common metals used in sheet metal fabrication include stainless steel, carbon steel, aluminum, copper, and galvanized steel. Each material offers unique properties such as corrosion resistance, strength-to-weight ratio, electrical conductivity, or aesthetic appeal. This material flexibility allows sheet metal parts to be tailored precisely to the functional and environmental demands of each industry.

One of the key strengths of sheet metal fabrication lies in precision cutting technologies. Modern fabrication facilities employ advanced tools such as laser cutting machines, plasma cutters, and water jet systems. Laser cutting, in particular, has become a cornerstone of high-quality sheet metal parts manufacturing. It delivers clean edges, minimal material waste, and exceptional accuracy, making it ideal for intricate designs and tight tolerances. Water jet cutting, on the other hand, is preferred for thicker materials or applications requiring no heat-affected zones, preserving the material’s structural integrity.

After cutting, the fabrication process moves into bending and forming, where flat metal sheets are shaped into three-dimensional components. Press brakes and custom dies are used to achieve precise angles and consistent bends. This stage is critical for ensuring that sheet metal parts fit seamlessly into larger assemblies. Advanced CNC-controlled bending machines allow for repeatable accuracy, even in high-volume production runs, reducing rework and improving overall efficiency.

Assembly is the final stage of sheet metal fabrication, where individual components are joined to create complete products or subassemblies. Depending on the application, assembly methods may include welding, riveting, fastening, or adhesive bonding. Welding is particularly common for structural sheet metal parts, providing strong, permanent joints that can withstand mechanical stress and environmental exposure. Skilled welding techniques ensure durability while maintaining the aesthetic and dimensional integrity of the finished product.

The versatility of sheet metal parts makes them essential across a wide range of industries. In the automotive industry, sheet metal fabrication is used to produce body panels, brackets, chassis components, and structural reinforcements. Precision and repeatability are critical in this sector, as even minor deviations can affect safety and performance. Sheet metal parts manufactured through advanced fabrication processes help automakers meet strict regulatory standards while optimizing vehicle weight and fuel efficiency.

In the aerospace industry, sheet metal parts must meet even higher standards of precision, strength, and reliability. Lightweight aluminum and high-strength alloys are commonly used to create aircraft skins, internal frames, and engine components. The ability of sheet metal fabrication to produce complex geometries with minimal material waste makes it an ideal solution for aerospace applications where performance and efficiency are paramount.

The electronics industry also relies heavily on sheet metal parts for enclosures, cabinets, heat sinks, and mounting structures. These components must provide protection, electromagnetic shielding, and effective heat dissipation while maintaining a compact and aesthetically pleasing design. Precision sheet metal fabrication ensures that electronic enclosures meet functional requirements and integrate seamlessly with internal components.

In construction and architecture, sheet metal parts are valued for their durability, flexibility, and design potential. From structural supports and roofing systems to decorative panels and custom fixtures, fabricated sheet metal offers both functional and aesthetic benefits. The ability to produce large-scale components as well as detailed custom designs makes sheet metal fabrication a key contributor to modern architectural innovation.

Beyond industry-specific applications, the growing emphasis on efficiency and sustainability has further highlighted the advantages of sheet metal fabrication. Optimized cutting layouts reduce material waste, while recyclable metals contribute to environmentally responsible manufacturing practices. Additionally, the durability and long service life of sheet metal parts reduce the need for frequent replacements, supporting long-term cost savings.

Below is a comparative table that highlights key aspects of sheet metal fabrication compared with other manufacturing methods:

| Aspect | Sheet Metal Parts Fabrication | Casting | Plastic Injection Molding |

|---|---|---|---|

| Material Options | Steel, Aluminum, Copper, Stainless Steel | Metals Only | Plastics Only |

| Precision | High | Medium | High |

| Design Flexibility | Excellent | Moderate | Excellent |

| Tooling Cost | Low to Moderate | High | High |

| Production Volume | Low to High | Medium to High | High |

| Lead Time | Short | Long | Long |

| Strength and Durability | High | High | Medium |

| Sustainability | Highly Recyclable | Recyclable | Limited Recycling |

As shown above, sheet metal parts offer a balanced combination of flexibility, strength, cost efficiency, and sustainability. This balance makes sheet metal fabrication an ideal choice for both prototyping and full-scale production.

A critical factor behind the success of sheet metal parts is the availability of full-service fabrication solutions. From initial design consultation and material selection to laser cutting, bending, welding, and finishing, integrated fabrication services streamline the production process. This end-to-end approach minimizes communication gaps, reduces lead times, and ensures consistent quality throughout the project lifecycle.

Surface finishing is another important aspect of sheet metal parts manufacturing. Processes such as powder coating, anodizing, polishing, and plating enhance corrosion resistance, improve appearance, and extend product lifespan. These finishing options allow manufacturers to meet both functional and branding requirements, especially for visible components or consumer-facing products.

Quality control plays a vital role in ensuring the reliability of sheet metal parts. Advanced inspection tools, including coordinate measuring machines and laser scanners, are used to verify dimensions and tolerances. Rigorous quality checks ensure that every component meets design specifications and industry standards before delivery.

Timely delivery is equally critical in today’s competitive market. Efficient production planning, automated machinery, and experienced engineering teams enable fabricators to meet tight deadlines without compromising quality. Reliable delivery schedules help customers maintain smooth operations and meet their own production commitments.

Sheet Metal Parts continue to serve as a foundation of modern manufacturing, supporting innovation across automotive, aerospace, electronics, construction, and many other industries. The versatility of sheet metal fabrication, combined with advanced cutting, bending, and assembly techniques, allows manufacturers to produce high-quality components that meet demanding technical and commercial requirements.

As industries move toward greater customization, efficiency, and sustainability, the role of sheet metal fabrication will only continue to grow. With comprehensive services ranging from laser cutting to welding, professional sheet metal fabricators are well-positioned to deliver precision, quality, and timely solutions for all fabrication needs. In an era where performance and reliability define success, sheet metal parts remain a trusted and indispensable manufacturing solution.

Eng

Eng  中文简体

中文简体