Precision stamping, casting quality - stamping metal parts help the efficient upgrading of manufacturing industry

2025.06.24

2025.06.24

Industry News

Industry News

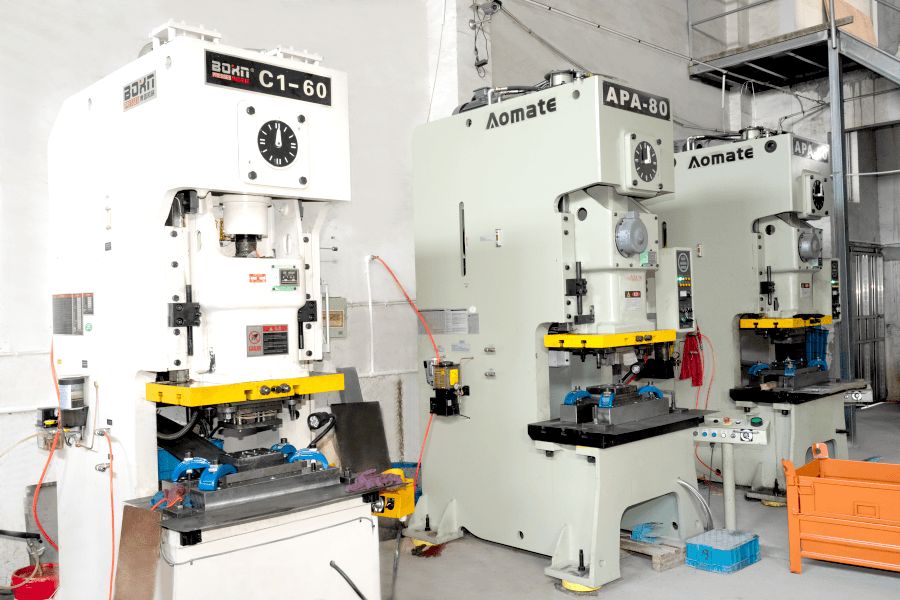

Stamping metal parts are made by the process of quickly and efficiently forming metal sheets or strips in the mold. Our stamping process combines high-precision mold design with high-speed punching equipment, which can complete various operations such as cutting, bending, stretching, punching, and pressing of materials in a very short time.

Relying on a professional mold R&D team and advanced CNC machining center, we can manufacture a variety of process molds including single-station molds, continuous molds, and compound molds to ensure that the parts always maintain stable precision under high-frequency stamping to meet the needs of products with different shapes and complex structures.

Millimeter-level dimensional accuracy is a significant feature of our stamping parts. Relying on advanced mold design and high-precision stamping technology, the dimensional tolerance of the product is strictly controlled between ±0.01 and ±0.05 mm. This level of precision not only ensures a high degree of matching between parts, but also ensures a smooth and stable assembly process. Especially in the field of automotive manufacturing, such as frame reinforcements, motor housings and other key components, strict dimensional requirements determine the safety and performance of the entire vehicle, and our stamping parts can accurately meet these high standards.

Stamping parts have excellent compression and impact resistance. We select a variety of metal materials such as high-strength carbon steel, stainless steel, aluminum alloy, copper alloy, etc., and combine heat treatment and surface strengthening technology to greatly improve the mechanical properties of parts. Even under complex working conditions with high-speed rotation or frequent mechanical impact, stamping parts can still maintain stable structural integrity and functional reliability. This sturdy and durable feature makes it widely used in fields such as automotive power systems, industrial machinery and electronic equipment that require extremely high strength and durability.

Surface flatness and processing consistency are important indicators to ensure the quality of stamping parts and subsequent processing. With the precise molding of precision molds and strict quality control, our stamping parts have a smooth surface without obvious burrs, deformation or indentations, ensuring excellent surface quality. The high-quality surface state not only reduces the difficulty and cost of subsequent processing, but also improves the effect of post-processing processes such as painting, electroplating, and welding, so that stamping parts can be directly used in terminal product assembly, meeting customers' dual needs for product aesthetics and functionality.

Application industry fields:

Automobile manufacturing: including body structural parts, engine brackets, shock absorption system components, door frames, transmission system fixing plates, etc. High strength and lightweight are equally important to help the performance of the whole vehicle and energy conservation and emission reduction goals.

Electronic equipment: used for notebook computers, power modules, shielding covers, connecting plates, shrapnel, battery covers, etc. in 5G communication equipment, with strict requirements on size, conductivity and thermal management performance.

Home appliance hardware: covering air conditioner brackets, refrigerator bases, internal support frames of rice cookers, washing machine fixing plates, etc., requiring stamping parts to have good corrosion resistance and structural strength to ensure long-term stable operation of home appliances.

New energy and industrial equipment: used in photovoltaic power station brackets, wind power gearboxes, electric vehicle battery trays, industrial control boxes and other fields, meeting the needs of strong weather resistance, convenient installation and standardized size.

Eng

Eng  中文简体

中文简体