Advanced sheet metal parts processing technology meets the high-standard manufacturing needs of various industries

2025.06.11

2025.06.11

Industry News

Industry News

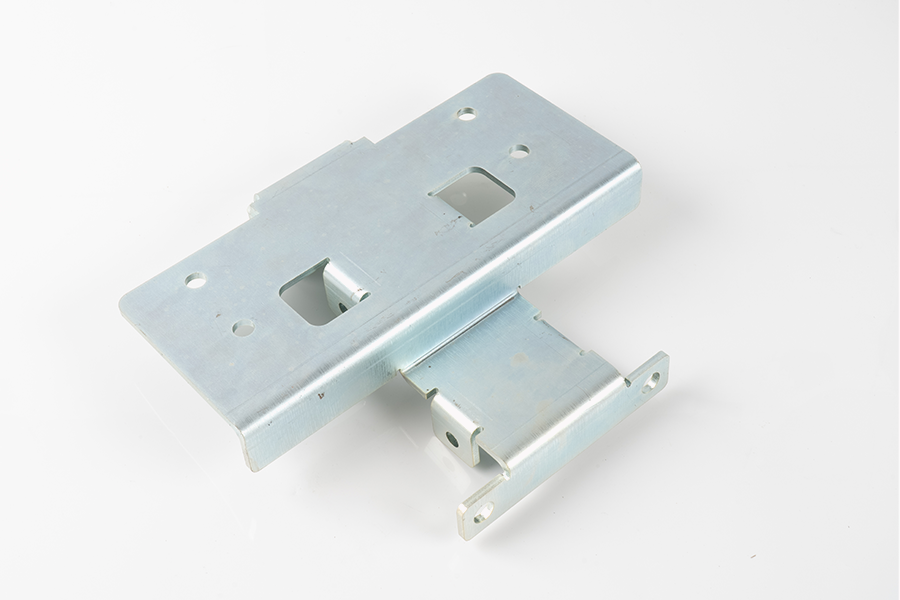

Sheet metal parts processing is a manufacturing process that transforms flat metal materials into various shapes and products through cutting, bending, assembly and other processes. This versatile processing method is widely used in many industries such as automobiles, aerospace, electronics, and construction, and has become an indispensable part of modern manufacturing. With the continuous advancement of technology, sheet metal parts processing has been able to meet the diverse needs from simple parts to complex components, and has become a core technology in many manufacturing fields.

In the process of sheet metal parts processing, steps such as precision cutting, bending and assembly are usually involved. Specifically, the cutting process includes laser cutting, water jet cutting, etc., the bending process uses presses and molds, and the assembly is achieved by welding, riveting or adhesive bonding. Whether in the manufacturing of automotive parts, aerospace equipment production, or in the processing of electronic equipment housings and building structural parts, sheet metal parts processing can provide precise dimensions and high-quality products.

The first step in sheet metal parts processing is usually precision cutting, and common cutting methods include laser cutting and water jet cutting. Laser cutting uses a high-intensity laser beam to cut metal materials. It has the advantages of high cutting accuracy and smooth edges. It is very suitable for the production of parts with complex shapes and precise structures. Water jet cutting uses high-pressure water flow to carry abrasives for cutting. This method can cut almost all metal materials without generating heat-affected zones, thus avoiding deformation of some metal materials caused by high temperatures. Our laser cutting and water jet cutting processes can ensure that while maintaining high precision, waste generation is minimized and production efficiency is improved. This allows our sheet metal parts processing products to not only meet strict dimensional requirements, but also effectively reduce costs and meet customers' dual needs for high product quality and short delivery time.

Bending in sheet metal parts processing is carried out by special bending machines or dies. In this process, the metal sheet is heated or cold-processed, and then the metal material is bent into the desired shape through pressure and tools. The bending process plays a vital role in the entire sheet metal parts manufacturing, which directly affects the dimensional accuracy, shape stability and structural strength of the final product. Our bending forming process can not only handle simple right-angle bends, but also complex curves and multi-angle bends, ensuring that the parts have excellent structural performance and stability in practical applications. In addition, using modern CNC equipment and automated bending technology, we can accurately control the bending angle and bending radius, thereby further improving the quality and consistency of the product.

At the final stage of sheet metal parts processing, parts need to be assembled to complete the manufacture of the final product. The assembly process usually includes welding, riveting and bonding. Welding technology uses high temperature to melt the metal parts and then connect them together, which can ensure the firm bonding of the metal parts and is widely used in products with high strength requirements. Riveting uses rivets to connect metal parts together, which is suitable for metal materials that are not suitable for welding. Bonding uses adhesives to fix metal parts together, which is suitable for some products that require airtightness and strong sealing.

sheet metal parts processing is widely used in multiple industries, covering a variety of manufacturing needs from simple parts to complex components. In the automotive industry, sheet metal parts processing is used to manufacture body shells, frame reinforcements, engine compartment components, etc. Through precise sheet metal parts processing, the dimensional accuracy and strength of automotive parts can be ensured to improve the safety and durability of the car.

In the aerospace industry, sheet metal parts processing is used to manufacture aircraft fuselages, engine components and precision structural parts. Since aerospace products require extremely high strength and precision, sheet metal parts processing plays an important role in this industry. Our sheet metal parts processing technology can meet these high standards and ensure the stability and reliability of aviation products.

In the electronics industry, sheet metal parts processing is mainly used to manufacture housings and structural support parts for various electronic devices, such as computer cases, power equipment housings, communication equipment housings, etc. These parts require not only precise dimensional control, but also good heat dissipation and anti-interference performance. Our sheet metal parts processing technology can ensure the quality of these products while meeting the requirements of efficient production.

In the construction industry, sheet metal parts processing is used to produce building decoration materials, structural support parts, door and window frames, etc. Through precise cutting and bending, sheet metal parts processing can provide buildings with high-quality, high-strength metal components to ensure the safety and beauty of the building structure.

Eng

Eng  中文简体

中文简体