High-precision and high-strength stamped metal parts production: core performance and process technology to meet stringent application requirements

2025.06.04

2025.06.04

Industry News

Industry News

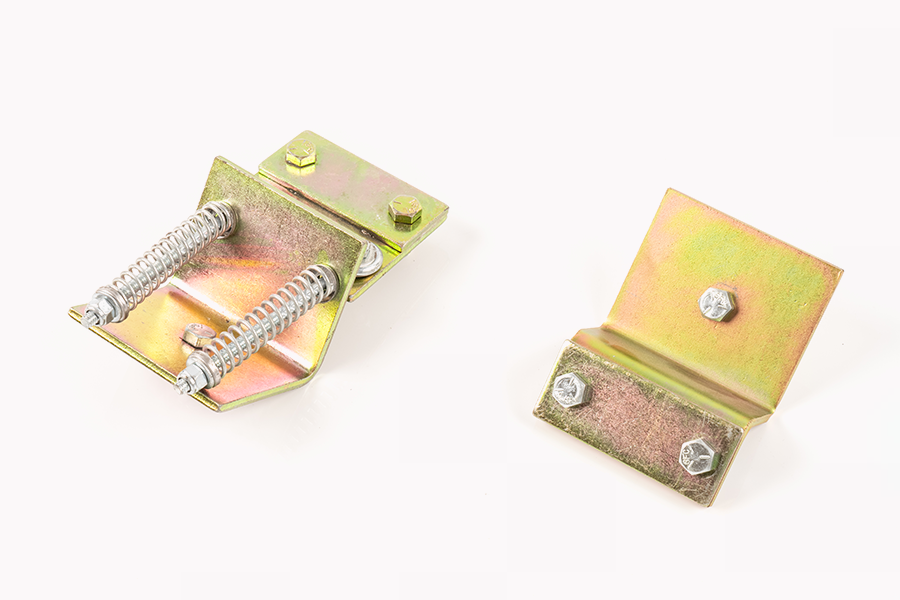

During the manufacturing process of stamped metal parts, dimensional accuracy, compressive strength, impact resistance and surface flatness are the four core performance indicators for evaluating their quality. These indicators directly determine whether the parts can meet stringent requirements in practical applications, especially in critical scenarios that require high strength and high precision.

Dimensional accuracy refers to the degree of match between the dimensions of the parts after stamping and the design drawings during the production process. In modern stamping technology, dimensional accuracy is the primary indicator for evaluating the quality of stamped metal parts. Our stamped metal parts can ensure that the dimensional error of the parts is controlled within a very small range and achieve millimeter-level accuracy through precise molds and high-speed stamping processes. This accuracy is crucial for key application scenarios such as frame reinforcement, motor housing, and precision connectors. For example, in the manufacture of motor housings, any slight dimensional deviation may cause the housing to mismatch with internal components, affecting the normal operation of the motor. Therefore, high-precision dimensional control can not only improve the compatibility and assembly accuracy of the product, but also ensure the functionality and safety of the final product.

Compressive strength refers to the ability of a part to resist deformation or rupture when subjected to external pressure. stamped metal parts are often used for structural parts that withstand external forces, so their compressive strength is crucial. For example, frame reinforcements are used in the automotive industry to withstand external force impacts on the car body, and parts are required to have high compressive strength to ensure that the car body structure can be effectively protected during a collision. In our stamped metal parts production, compressive strength is guaranteed by selecting high-strength materials and optimizing the process flow. Especially when producing some parts that are subjected to heavy loads or high pressure environments, precise control of the stamping process can maximize the mechanical properties of the material and ensure the stability and durability of the parts.

Impact resistance refers to the ability of a part to maintain structural integrity without damage when it is subjected to instantaneous impact or severe vibration. Especially in the fields of automobile manufacturing, electronic equipment housing, etc., parts are often affected by external impact or vibration, so impact resistance is a very important quality standard. Through reasonable material selection and precise process design, our stamped metal parts can have good impact resistance while ensuring high precision. This means that whether it is used for automotive collision energy absorption devices or protective housings for electronic products, these parts can maintain stable performance in complex environments and reduce damage caused by external impacts.

Surface flatness refers to the smoothness and flatness of the surface of a part, reflecting the fineness of the stamping process. Surface flatness has an important impact on the appearance, assembly accuracy and corrosion resistance of the part. For application scenarios that require good appearance and high surface quality, such as precision connectors or home appliance housings, surface flatness is crucial.

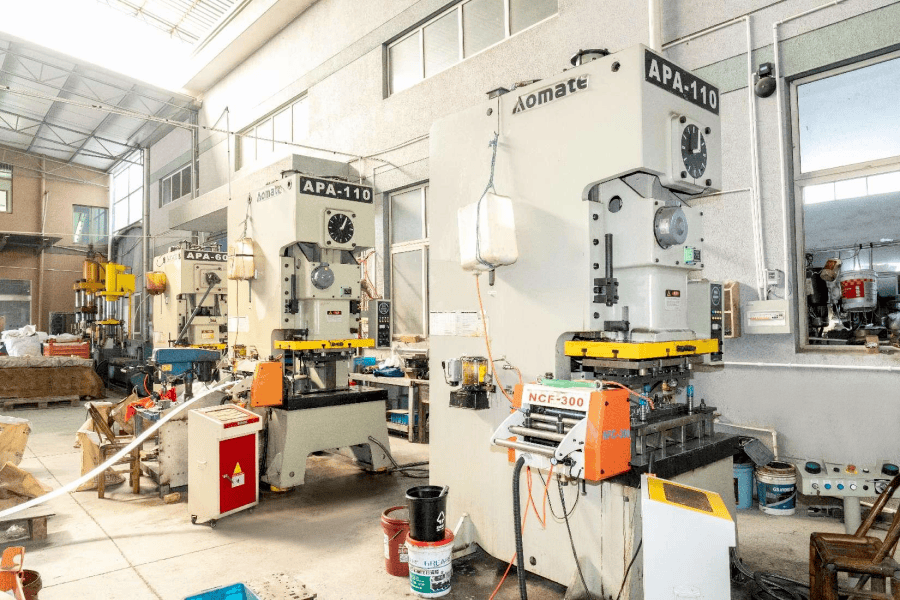

Provide technical stamped metal parts production of different sizes, using a variety of advanced stamping process technologies to ensure that each part can meet the requirements of high precision and high stability. Specifically, we mainly use three different types of mold technologies-single mold, continuous mold and step-by-step mold. The combination of these technologies enables us to provide the most suitable solutions for different production needs.

Single mold technology is the most basic stamping mold technology, which is suitable for the production method of single stamping. With single mold technology, we can process a complete part in each stamping. This method is suitable for small batch production or parts with relatively simple structures, can provide high precision, and can greatly reduce the time of mold replacement and adjustment in small batch production.

Continuous mold technology uses multiple stamping steps of the mold to achieve multiple processing operations in each stamping. This enables us to continuously perform different stamping, shearing, bending and other processes on a single stamping machine to achieve higher production efficiency. Continuous dies are suitable for mass production, especially for parts with complex structures that require multiple operations. It can greatly improve production efficiency and ensure the stability and consistency of parts.

Step-by-step die technology is suitable for scenarios that require more complex and refined shapes of stamped parts. Step-by-step dies use multiple stamping stations or die combinations to gradually complete the entire forming process of the part through a one-time die configuration and continuous multi-step stamping operations. These processes usually include shearing, punching, bending, stretching, forming, etc. The shape of the part will gradually be refined and adjusted in each step of the stamping process until it is completed. This technology is usually used to produce parts with complex shapes or that require high-precision cutting. It can improve the accuracy of the parts and ensure high consistency during mass production.

Eng

Eng  中文简体

中文简体