What are the unique advantages of using stamped metal parts in automobile manufacturing?

2025.05.16

2025.05.16

Industry News

Industry News

1. High precision and consistency: the cornerstone of building automotive structural reliability

Automobile manufacturing has extremely strict requirements on the dimensional accuracy and assembly consistency of parts. Taking the engine compartment seal as an example, the gap between it and the surrounding parts must be controlled within ±0.1mm, otherwise it may cause oil leakage or abnormal noise; and the dimensional deviation of the frame connector may directly affect the torsional stiffness of the body, thereby threatening driving safety. The stamping process can achieve millimeter-level or even sub-millimeter-level dimensional control through the synergy of precision molds and high-speed stamping equipment. For example, the integrated stamping rear floor of Tesla Model 3 adopts progressive die technology, and a single stamping can complete the forming of complex curved surfaces and reinforcement ribs. The tolerance range is strictly controlled within ±0.02mm, which reduces more than 300 welds compared with traditional welding processes. It not only improves the body stiffness, but also significantly reduces the risk of dimensional deviation caused by welding deformation.

In mass production, the consistency advantage of the stamping process is more prominent. Through the cooperation of CNC punching machines and automated feeding systems, a single production line can produce thousands of stamping parts per hour, and the dimensional fluctuation rate is less than 0.5%. This stability is particularly important in the production of precision connectors, sensor brackets and other parts. For example, in the stamping production of a certain intelligent driving laser radar bracket, the online detection system monitors the dimensional deviation in real time, and combined with the mold wear compensation technology, the dimensional consistency of millions of products reaches 99.99%, ensuring the assembly accuracy and signal stability of the radar module.

2. Lightweight and performance balance: the core technology driving the new energy vehicle revolution

In the field of new energy vehicles, the lightweight potential and structural strength advantages of stamped metal parts are fully released. Taking the Audi A8 as an example, the proportion of aluminum alloy in its body stamping parts is as high as 71%. By optimizing the material distribution and stamping process, the vehicle weight is reduced by 48kg and the cruising range is increased by about 5% while ensuring collision safety. Behind this achievement is the deep adaptability of the stamping process to high-strength materials. For example, the stamping of dual-phase steel (DP steel) and phase transformation induced plasticity steel (TRIP steel) needs to overcome the difficulties of large material rebound and low forming limit. Through process improvements such as step-by-step stamping and local heating, complex shape forming of materials with tensile strength above 1000MPa can be achieved, while the rebound amount is controlled within 0.5%.

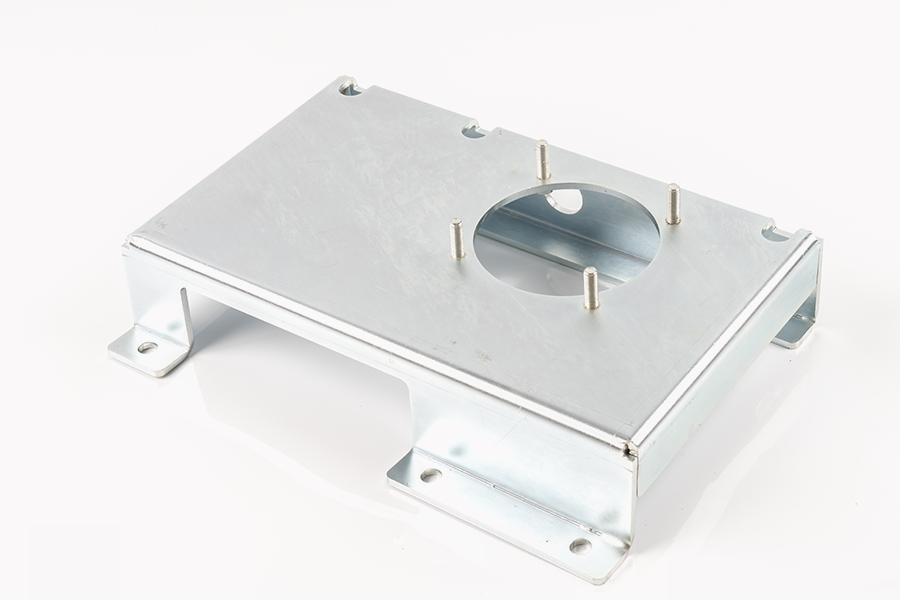

In the design of battery pack shells, the stamping process further demonstrates the dual advantages of lightweight and functional integration. Taking the lower shell of a new energy vehicle battery pack as an example, 6 series aluminum alloy is used to form an integrated body through deep drawing and local thickening process, which is 30% lighter than the traditional stamping + welding solution. At the same time, through the built-in reinforcement ribs and collision energy absorption structure, the shell deformation is less than 3mm under 10J energy impact, meeting the IP67 waterproof and 1 meter drop test standards. The stamping process can also realize the integrated design of the shell and the cooling water channel, and the battery heat dissipation efficiency can be improved by more than 20% by stamping out the microchannel structure.

3. Scaled breakthrough in cost and efficiency: Reshaping the automobile manufacturing value chain

The scaled advantages of stamping technology are fully reflected in automobile manufacturing. Taking the door inner panel production line of a certain model of Toyota Motor as an example, by adopting multi-station progressive dies and high-speed punch presses (stamping frequency of 30 times/minute), the annual production capacity of a single line can reach 500,000 pieces, which is 400% more efficient than the traditional single-station mold. Through laser welding technology and layout optimization algorithm, the material utilization rate is increased from 65% to 85%, and the cost of raw materials per piece is reduced by 15%. In the mold design stage, the simulation software is used to predict the material flow and stress distribution, which can reduce the number of mold trials by more than 30%, further shortening the development cycle.

For customized needs, the stamping process also shows flexibility. For example, in the automotive modification market, a company has achieved rapid changeover of products of different sizes, from SUV pedals to pickup truck cargo box covers, through modular mold design. The changeover time is shortened from 8 hours in traditional processes to 2 hours, and the cost of a single changeover is reduced by 60%. This flexible production capability is particularly important in the production of small batches and multiple varieties of new energy vehicle battery trays, hydrogen fuel cell shells, etc. For example, a fuel cell shell supplier can complete the entire process from design to mass production within 72 hours through rapid adjustment of the stamping process, meeting customers' stringent requirements for delivery cycles.

4. Surface quality and functional breakthroughs: defining new standards for automotive parts

The surface quality of stamped metal parts is directly related to the durability and aesthetics of the car. Taking automobile chassis stamping parts as an example, the surface flatness must reach Ra0.8μm or less to ensure the uniformity and anti-corrosion performance of the electrophoretic coating. By optimizing the stamping speed, lubrication conditions and mold surface treatment (such as TD coating), scratches, orange peel and other defects can be effectively reduced, and the coating defect rate can be reduced from 3% to below 0.5%. In high-end models, stamping parts often need to meet special surface requirements such as mirror polishing or texture etching. For example, the air intake grille of a luxury brand model has achieved 0.01mm line accuracy and three-dimensional visual effects through precision stamping and chemical etching processes.

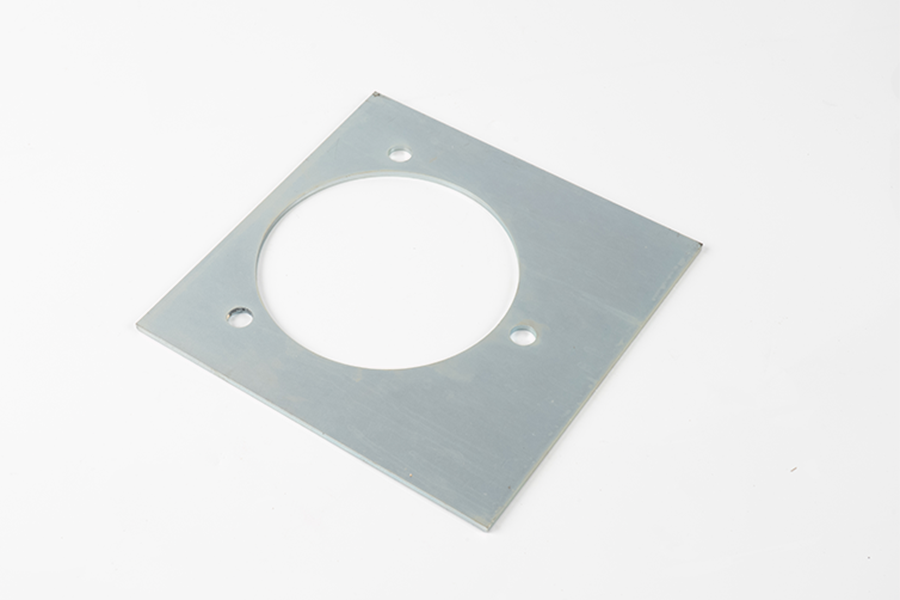

In terms of functionality, stamping technology is driving the development of components towards integration and intelligence. For example, the motor housing of a new energy vehicle is stamped with heat dissipation fins and electromagnetic shielding structures, which improves the heat dissipation efficiency by 30% and reduces electromagnetic interference to below -80dB; while the smart driving sensor bracket is stamped with integrated guide grooves and positioning holes, so that the installation accuracy of the radar module reaches ±0.05mm and reduces the use of additional fixings. The stamping process can also realize innovative designs such as lightweight honeycomb structures and variable thickness plates. For example, the door anti-collision beam of a certain model is stamped with a local thickening area, which reduces the weight by 10% and increases the side collision absorption energy by 25%.

Eng

Eng  中文简体

中文简体