Why Are Stamping Metal Parts Crucial for Modern Manufacturing Industries?

2025.10.23

2025.10.23

Industry News

Industry News

What Makes Stamping Metal Parts Efficient and Cost-Effective?

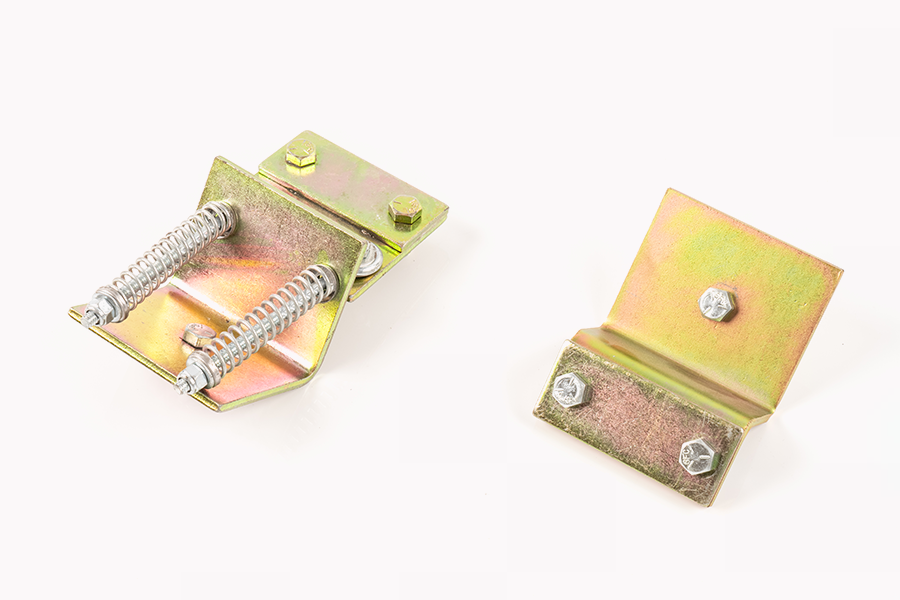

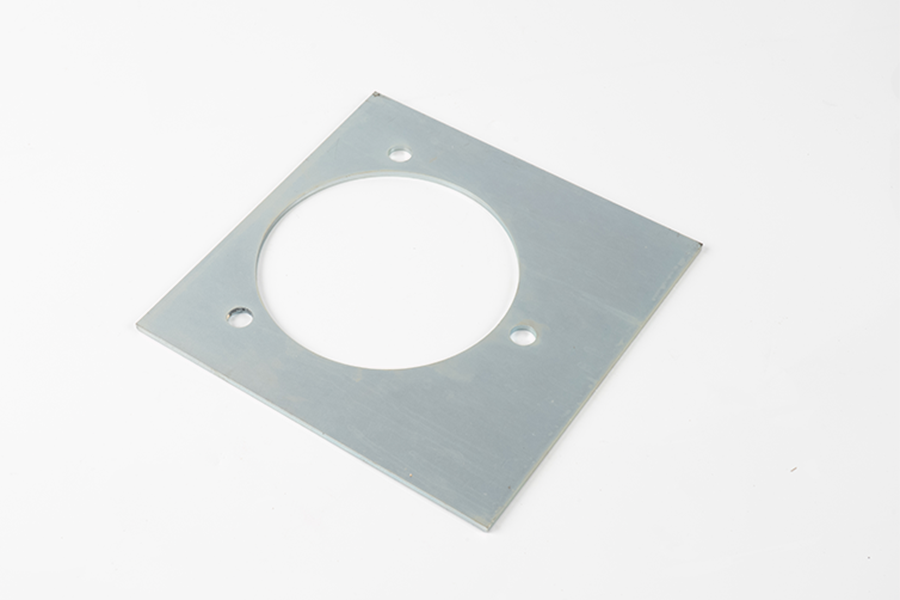

Stamping metal parts are produced using a high-precision stamping process that allows for mass production with consistent quality. Compared to other fabrication methods such as machining or casting, stamping provides faster production cycles, reducing manufacturing time and costs. The process uses dies and presses to cut, bend, or form metal sheets into desired shapes with high accuracy. This efficiency makes stamped parts ideal for industries requiring large-scale production, such as automotive components, electronic housings, and household appliances.

Moreover, the ability to produce complex shapes in a single stamping operation reduces the need for secondary processing, further lowering costs and improving overall production efficiency. This combination of speed, precision, and cost-effectiveness has made stamping metal parts a preferred choice for manufacturers worldwide.

How Does Stamping Enhance the Strength and Durability of Metal Parts?

One of the key advantages of stamped metal parts is their structural integrity. The stamping process applies precise pressure and deformation techniques that improve the mechanical strength of the metal, ensuring that the finished parts can withstand stress and heavy loads. For applications in the automotive and aerospace industries, where safety and durability are critical, stamping metal parts provide consistent strength and reliability.

Additionally, modern stamping techniques allow for material optimization, reducing weight while maintaining durability. This is especially important for industries such as electric vehicles and electronics, where lightweight components can enhance efficiency and performance without compromising safety.

Why Are Stamping Metal Parts Ideal for Custom and Complex Designs?

Stamping technology has evolved to accommodate intricate and precise designs that would be difficult to achieve with traditional machining or casting. With advanced die engineering and CNC-controlled presses, manufacturers can produce metal parts with fine details, tight tolerances, and complex geometries.

This capability makes stamping metal parts highly suitable for customized applications, including precision automotive components, intricate electronic connectors, and decorative metal panels. The combination of high repeatability and accuracy ensures that each stamped part meets exact specifications, which is crucial in quality-sensitive industries.

How Does Stamping Metal Parts Support Sustainable Manufacturing?

Modern stamping processes also contribute to sustainable manufacturing practices. Since stamping uses sheet metal efficiently with minimal waste, it reduces the environmental footprint of metal fabrication. Additionally, many stamping operations now utilize recyclable metal sheets and energy-efficient presses, further enhancing sustainability.

By optimizing material usage and enabling high-volume production with minimal scrap, stamping metal parts not only improve cost-effectiveness but also align with eco-friendly production goals. This is increasingly important as industries seek to meet green manufacturing standards and reduce overall resource consumption.

What Are the Key Industries Benefiting from Stamping Metal Parts?

Stamping metal parts are widely used across automotive, electronics, appliance, aerospace, and industrial equipment sectors. In the automotive industry, they are used for body panels, brackets, chassis components, and reinforcement parts. In electronics, stamping produces housings, connectors, and shielding components. Appliances such as washing machines, refrigerators, and air conditioners rely on stamped metal parts for structural and functional elements.

The versatility, precision, and efficiency of stamped metal parts make them indispensable across multiple industries, ensuring reliable performance, high-quality products, and cost-effective manufacturing.

Stamping metal parts combine precision, efficiency, durability, and design flexibility, making them a cornerstone of modern manufacturing. Whether for automotive, electronics, or appliance production, stamped components offer high-quality, cost-effective, and sustainable solutions that meet the demanding requirements of contemporary industrial applications. Investing in advanced stamping technology ensures consistent performance, reduced production costs, and superior product quality across a wide range of applications.

Eng

Eng  中文简体

中文简体