How Can Sheet Metal Fabrication Help You Create High-Precision Industrial Components?

2025.10.16

2025.10.16

Industry News

Industry News

What Exactly Is Sheet Metal Fabrication?

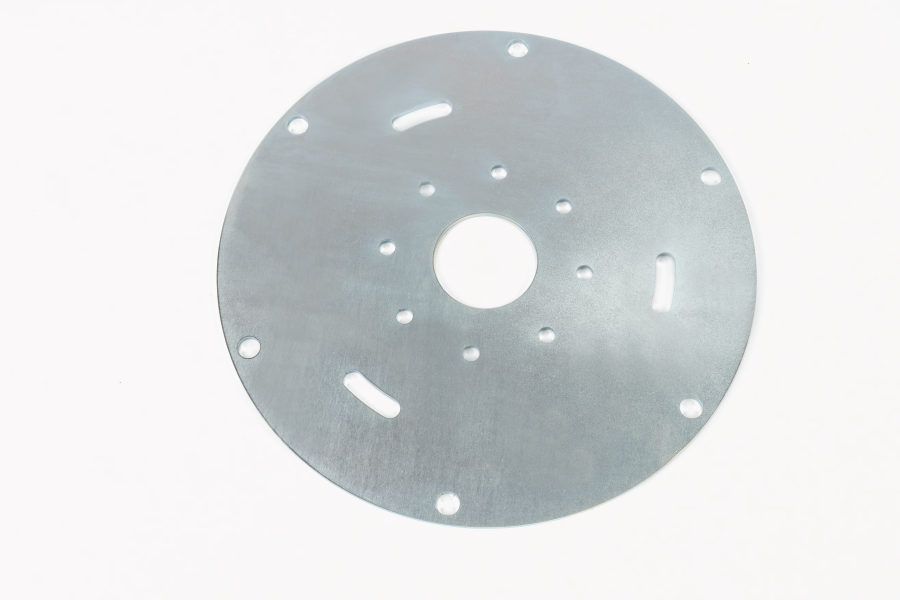

Sheet metal fabrication involves several sequential steps that convert a flat piece of metal into a finished product. The main operations include laser cutting, punching, bending, welding, and surface finishing. Materials such as steel, aluminum, and stainless steel are commonly used, each chosen based on their strength, corrosion resistance, and formability.

From simple enclosures to intricate structural components, sheet metal fabrication enables high-volume, cost-effective, and repeatable production of customized parts tailored to the needs of modern industries.

What Are the Core Processes Involved in Sheet Metal Fabrication?

The production workflow typically combines multiple precision steps to achieve the required geometry and performance. Below is a breakdown of the key processes used in modern sheet metal fabrication:

| Process | Description | Common Equipment |

| Cutting | Involves removing material from flat metal sheets to form desired shapes and dimensions. | Laser cutter, water jet cutter, plasma cutter |

| Bending | Forms angles or curves in the sheet using mechanical force without cutting the material. | Press brake, folding machine |

| Welding | Joins multiple pieces together by melting their edges and fusing them into one solid unit. | MIG/TIG welder, spot welder |

| Assembly | Combines fabricated parts through fastening or bonding for the final product structure. | Riveting tools, screws, adhesives |

| Finishing | Enhances appearance and durability with coatings or polishing processes. | Powder coating, anodizing, sandblasting |

Why Do Industries Depend on Sheet Metal Fabrication?

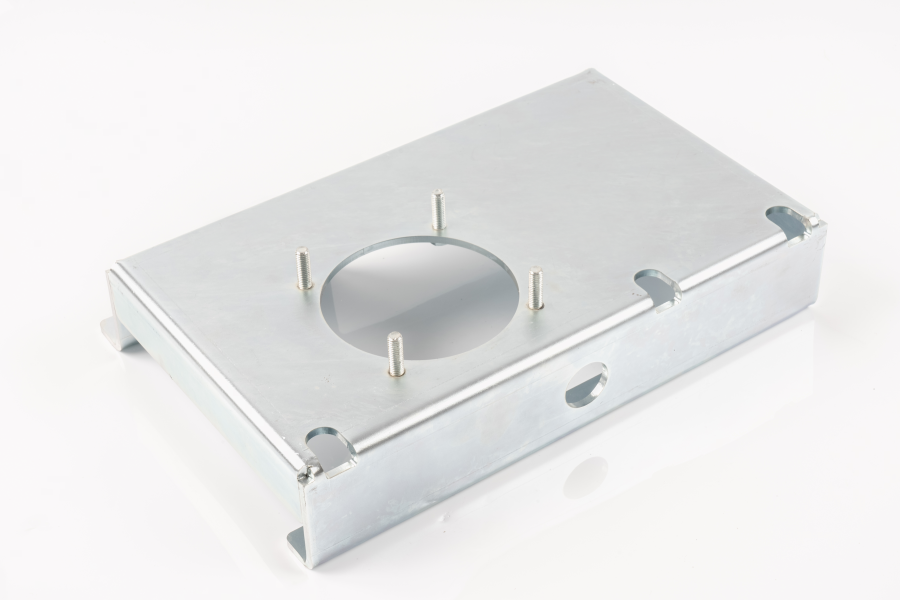

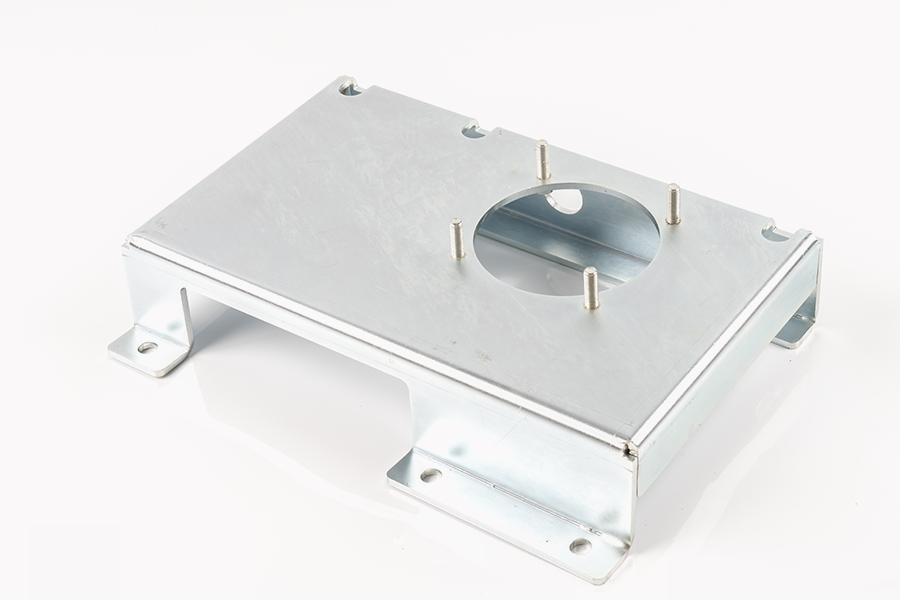

Many industries rely on sheet metal fabrication for its flexibility, strength, and adaptability. Automotive manufacturers use it to create body panels, engine brackets, and chassis components. Aerospace companies depend on it for lightweight structural parts that maintain precision under high stress. In electronics, it enables the creation of enclosures and heat-dissipating housings that protect sensitive components.

Beyond these sectors, sheet metal fabrication is essential in renewable energy systems, HVAC units, and architectural frameworks, where both structural integrity and aesthetic appeal are required.

How Does Modern Technology Improve Fabrication Precision?

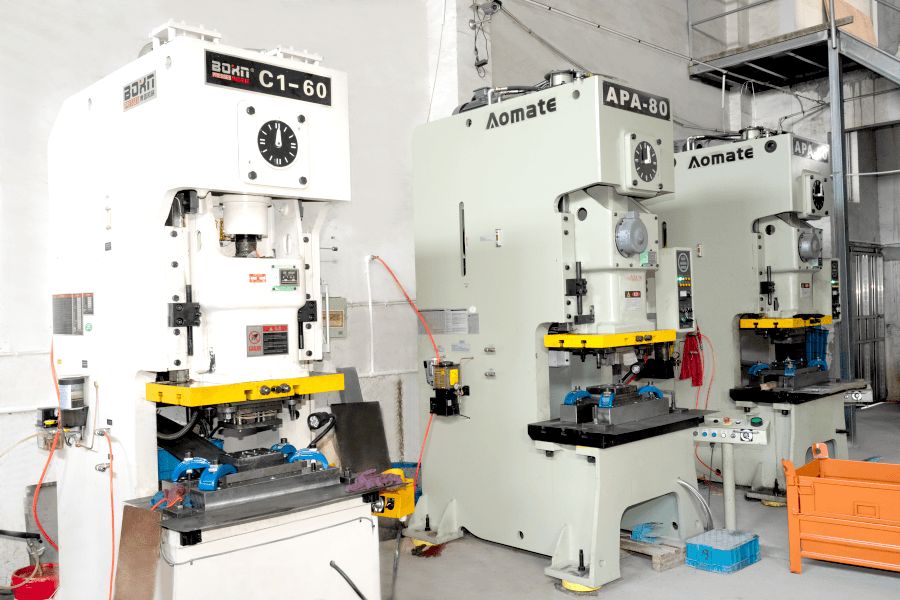

Advances in CNC (Computer Numerical Control) machinery and automated robotics have revolutionized sheet metal fabrication. Laser cutting machines can now achieve micrometer-level accuracy, while bending and forming operations are fully programmable to ensure consistency across large production runs. 3D modeling and simulation software also allow engineers to predict deformation, stress points, and tolerances before physical production begins, minimizing waste and optimizing design efficiency.

What Benefits Can You Expect from Professional Sheet Metal Fabrication Services?

Choosing a reliable sheet metal fabrication service offers several advantages for your project:

High Precision: CNC-controlled processes ensure consistent, repeatable accuracy.

Design Flexibility: Easily accommodates complex geometries and customized shapes.

Durability: Produces strong, corrosion-resistant parts suitable for demanding applications.

Cost Efficiency: Reduces material waste and assembly time through automated production.

Scalability: Supports both prototype development and high-volume production.

How Can We Support Your Fabrication Projects?

We provide a full range of sheet metal fabrication services—from laser cutting to welding, forming, and finishing. Our advanced equipment and experienced technicians ensure precision, reliability, and timely delivery for every order. Whether you need single custom components or mass-produced assemblies, we can meet your exact specifications while maintaining strict quality control standards.

By integrating engineering expertise with state-of-the-art production capabilities, we help clients achieve the perfect balance between performance, aesthetics, and cost efficiency in every fabricated product.

Why Choose Sheet Metal Fabrication for Your Next Project?

Sheet metal fabrication stands as one of the most versatile and efficient manufacturing methods available today. It combines strength, flexibility, and precision to produce durable products across multiple industries. With innovations in automation, design tools, and material science, modern fabrication continues to set new benchmarks for quality and efficiency. Partnering with a professional fabrication team ensures that your components meet the highest standards—both in performance and reliability—no matter how complex your requirements may be.

Eng

Eng  中文简体

中文简体