How Are Fabricated Assemblies Transforming Modern Manufacturing Processes?

2025.10.09

2025.10.09

Industry News

Industry News

What Are Fabricated Assemblies and Why Are They So Important?

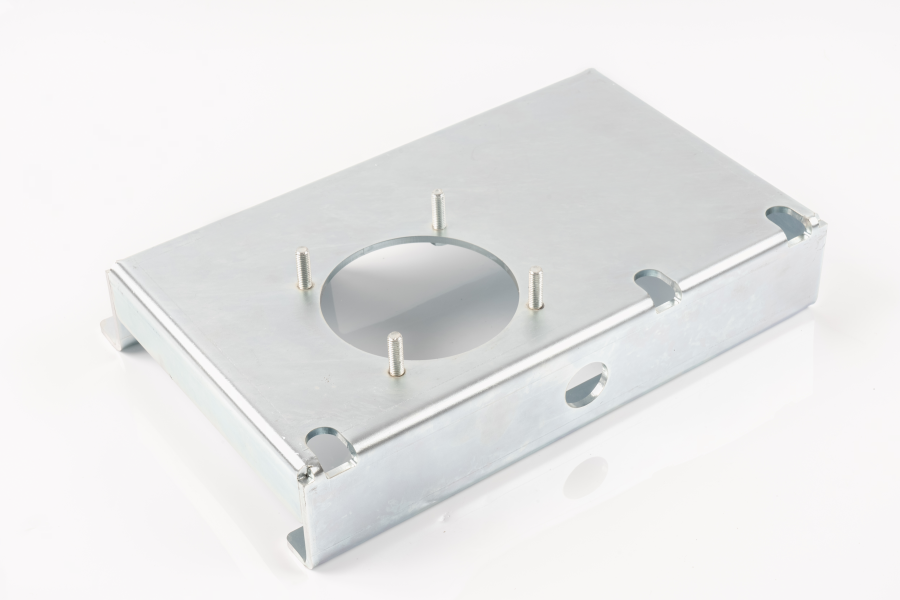

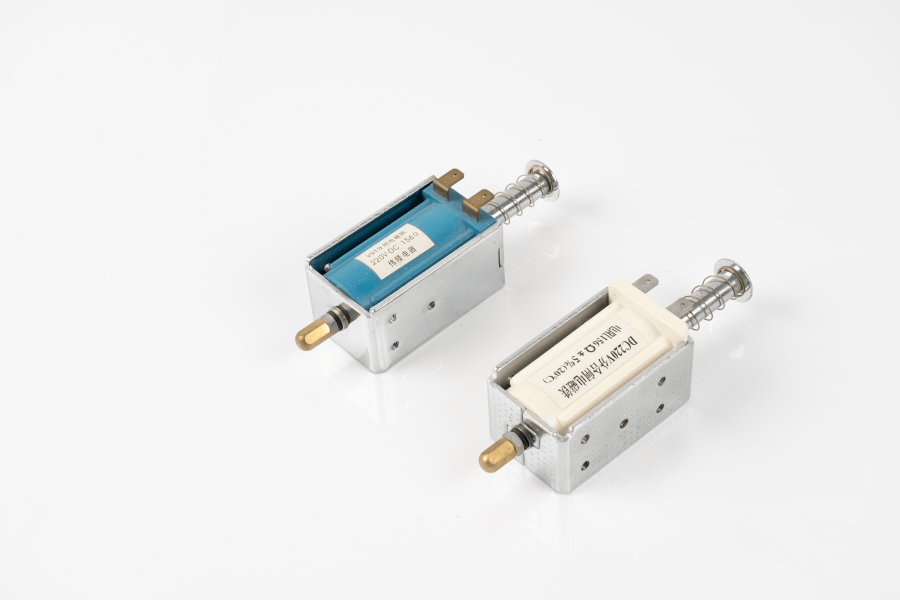

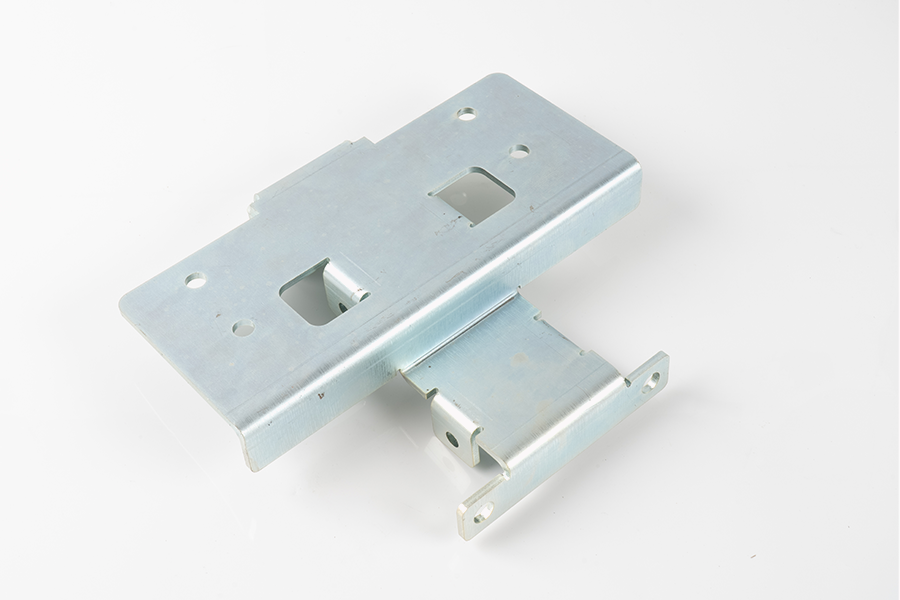

Fabricated assemblies refer to complex components that are created through multiple fabrication processes, such as cutting, welding, bending, machining, and assembling. Instead of manufacturing a single part, companies produce an integrated structure that can perform multiple functions or fit precisely into larger systems.

These assemblies are widely used in aerospace, automotive, energy, medical, and construction industries, where reliability, precision, and consistency are critical. The integration of advanced technologies such as CNC machining, laser cutting, and robotic welding allows manufacturers to achieve superior accuracy and repeatability.

By outsourcing or partnering with professional fabricated assemblies suppliers, companies can focus on core competencies like design and system integration while ensuring that every component meets required specifications.

How Do Different Materials Influence Fabricated Assembly Performance?

Material selection is one of the most decisive factors in the performance of any fabricated assembly. Depending on the application, manufacturers choose from a range of metals and alloys such as steel, aluminum, stainless steel, and titanium, or non-metal materials like composites and plastics.

Each material offers unique advantages:

| Material Type | Key Properties | Typical Applications |

| Stainless Steel | Corrosion-resistant, strong, durable | Medical equipment, marine hardware |

| Aluminum | Lightweight, excellent thermal conductivity | Automotive frames, aerospace components |

| Carbon Steel | Cost-effective, high tensile strength | Machinery, structural parts |

| Titanium | Strong, light, heat-resistant | Aerospace, defense industries |

| Composite Materials | High strength-to-weight ratio, customizable | Sporting goods, electronics housing |

The choice of material directly affects the strength, weight, and resistance of the assembly. For example, aluminum and titanium are preferred for lightweight structures, while carbon steel is ideal for heavy-duty applications where strength is paramount.

How Does the Fabrication Process Ensure Precision and Quality?

Producing high-quality fabricated assemblies requires a combination of skilled craftsmanship and advanced machinery. Each step—from design to final inspection—is optimized to minimize errors and achieve consistent performance.

The typical fabrication process includes:

Design and Engineering: Using CAD software, engineers create 3D models and simulations to test fit, stress, and durability.

Material Cutting: Advanced methods such as laser cutting, plasma cutting, or waterjet cutting are employed for precise dimensioning.

Forming and Welding: Components are shaped using bending, rolling, or stamping, then assembled through robotic or manual welding.

Machining and Finishing: Surface finishing, powder coating, or polishing enhances appearance and protection.

Quality Control: Every assembly undergoes dimensional inspection, load testing, and surface analysis to meet ISO and industry-specific standards.

This structured workflow ensures that fabricated assemblies not only meet design intent but also maintain long-term performance reliability under diverse operating conditions.

Why Are Fabricated Assemblies Essential Across Different Industries?

The adaptability and efficiency of fabricated assemblies make them integral to a wide range of industrial applications:

Automotive Industry: Used for chassis components, brackets, frames, and engine mounts that demand both strength and weight optimization.

Aerospace Industry: Fabricated assemblies provide lightweight yet durable structures that can withstand extreme conditions.

Construction Equipment: Structural assemblies are used in cranes, excavators, and industrial frameworks.

Energy and Power Sector: Employed in turbines, generators, and transmission systems for high-efficiency operations.

Medical and Electronics: Precision assemblies ensure accuracy and cleanliness for critical equipment manufacturing.

Their versatility allows for customized fabrication solutions tailored to specific industrial needs, ensuring that every project achieves peak operational performance.

How Is Technology Enhancing the Future of Fabricated Assemblies?

Technological advancement continues to revolutionize the world of fabricated assemblies. Automation, artificial intelligence, and data-driven manufacturing are enabling faster production cycles and improved accuracy.

Robotic Welding: Ensures uniform joints and reduces human error.

3D Laser Scanning: Improves precision during alignment and inspection.

Digital Twin Simulation: Helps predict performance and detect design flaws before fabrication begins.

Additive Manufacturing Integration: Allows for hybrid processes combining 3D printing and traditional fabrication.

Furthermore, sustainability is becoming a key focus. Many fabricated assemblies manufacturers are adopting eco-friendly production methods, such as energy-efficient machinery, waste recycling, and the use of recyclable materials.

What Does the Future Hold for Fabricated Assemblies?

The future of fabricated assemblies lies in customization, automation, and global collaboration. As manufacturing continues to shift toward Industry 4.0, companies are investing in digital platforms that streamline design-to-production workflows.

Global supply chains are increasingly integrating OEM/ODM fabrication services, allowing clients to receive ready-to-install assemblies that reduce assembly time and enhance cost-effectiveness.

With precision engineering, smart manufacturing, and advanced material science converging, fabricated assemblies will continue to drive innovation across multiple industries—delivering efficiency, strength, and sustainability in every component.

Eng

Eng  中文简体

中文简体