How Are Sheet Metal Parts Shaping the Future of Modern Manufacturing?

2025.10.08

2025.10.08

Industry News

Industry News

What Are Sheet Metal Parts and Why Are They So Essential in Manufacturing?

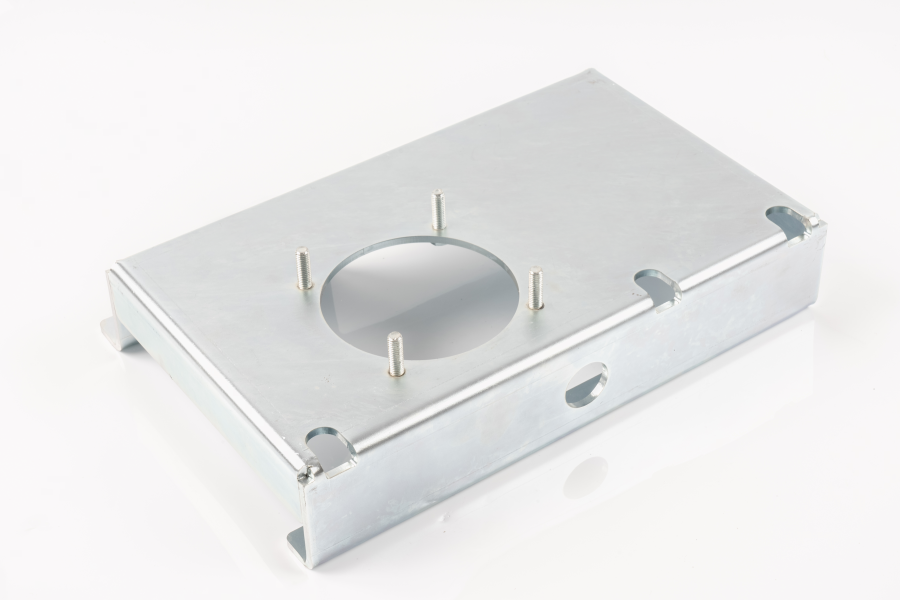

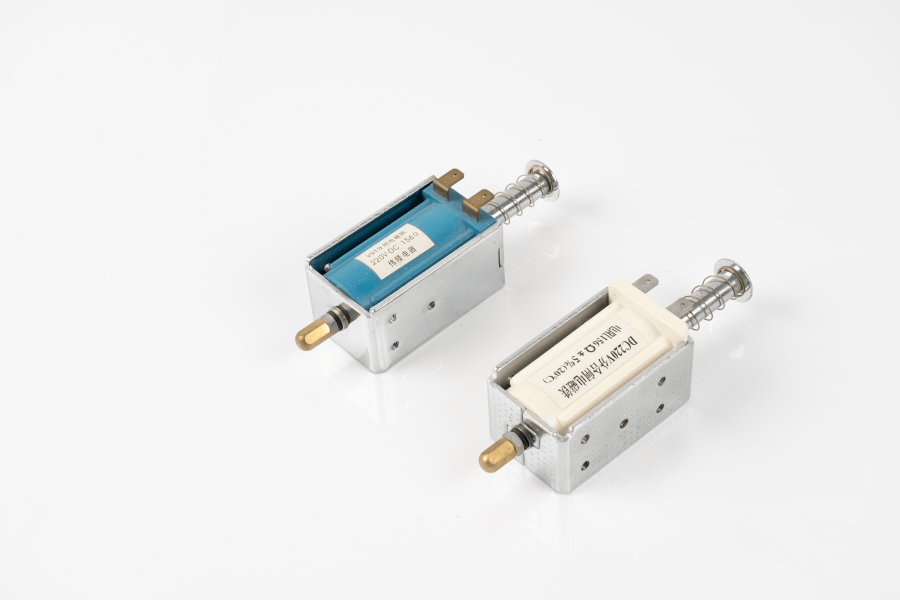

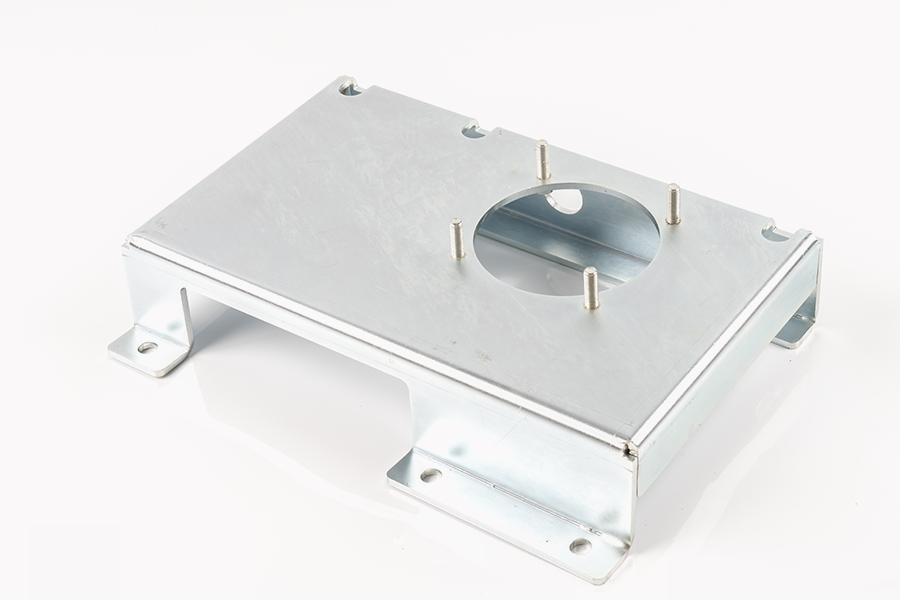

Sheet Metal Parts are components formed by cutting, bending, punching, stamping, or welding thin sheets of metal, typically made from materials like stainless steel, aluminum, carbon steel, brass, or copper. These parts can vary from simple brackets and enclosures to complex assemblies for industrial machinery or consumer products.

The true value of sheet metal fabrication lies in its flexibility—it allows manufacturers to produce high-precision parts in large quantities at relatively low cost. Moreover, these parts offer excellent strength-to-weight ratio, corrosion resistance, and adaptability to surface treatments such as powder coating, plating, or anodizing.

Whether used in the chassis of an automobile, the frame of an electronic device, or the body of an air conditioner, Sheet Metal Parts ensure durability, functionality, and design integrity in nearly every modern product.

How Is the Sheet Metal Fabrication Process Evolving with Advanced Technology?

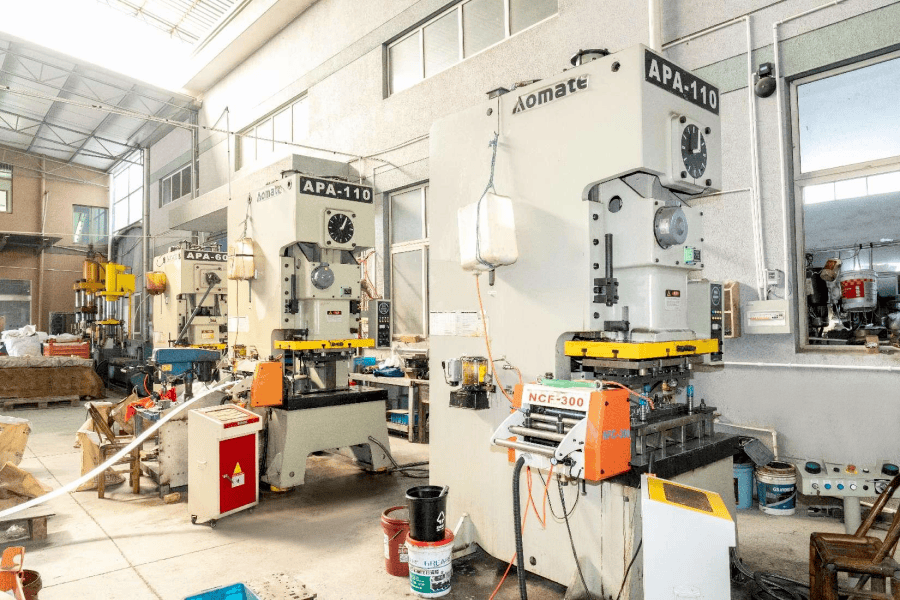

Traditional sheet metal production relied heavily on manual operations and basic machinery. However, with the rise of Industry 4.0 and smart manufacturing, the process has evolved dramatically. Today, CNC machining, laser cutting, and robotic bending dominate the field, ensuring unprecedented accuracy and repeatability.

Key advancements include:

CNC Laser Cutting: Provides high-speed, precise cutting for complex geometries with minimal waste.

Robotic Welding: Ensures consistent welds and reduces human error.

Automated Bending Machines: Improve productivity while maintaining dimensional accuracy.

3D CAD and CAM Software: Allow engineers to simulate designs before production, reducing prototyping time and cost.

These innovations not only improve production efficiency and quality but also help companies meet the growing demand for customized and lightweight components in industries such as electric vehicles and consumer electronics.

Why Are Sheet Metal Parts Critical in the Automotive and Aerospace Industries?

In the automotive sector, Sheet Metal Parts are essential for producing car bodies, chassis, engine components, and structural reinforcements. Modern vehicles rely on lightweight yet durable materials to improve fuel efficiency and reduce emissions. Aluminum and high-strength steel sheet components are therefore in high demand.

Meanwhile, in aerospace applications, precision and performance are paramount. Sheet Metal Parts are used in the construction of fuselages, wings, and cabin structures. These parts must meet rigorous safety and quality standards, capable of withstanding extreme temperatures, vibrations, and air pressures.

| Industry | Sheet Metal Application | Key Benefit |

|---|---|---|

| Automotive | Body panels, frames, brackets | Lightweight and cost-effective |

| Aerospace | Aircraft fuselage, landing gear | High strength and precision |

| Electronics | Enclosures, heat sinks, housings | Efficient thermal management |

| Construction | Roofing, ducts, structural elements | Long-term durability |

| Energy | Solar panel frames, wind turbine housings | Weather and corrosion resistance |

The combination of efficiency, versatility, and durability makes Sheet Metal Parts indispensable in industries where both performance and safety are non-negotiable.

How Do Sheet Metal Parts Support Sustainability and Energy Efficiency?

Sustainability is becoming a central focus in modern production, and Sheet Metal Parts contribute significantly to eco-friendly manufacturing. Metals like aluminum and steel are 100% recyclable, allowing manufacturers to minimize waste and reduce environmental impact.

In addition, advanced sheet metal design techniques optimize material usage, leading to less scrap generation and lower energy consumption during fabrication. The development of lightweight components for vehicles and machinery also helps cut fuel use and carbon emissions.

Moreover, in renewable energy applications, sheet metal is widely used to build solar panel frames, wind turbine housings, and battery enclosures—supporting the global shift toward cleaner energy systems.

What Are the Key Quality Factors in Producing High-Performance Sheet Metal Parts?

To maintain the highest level of reliability, manufacturers must focus on several critical factors during production:

Material Selection: Choosing the right metal based on application requirements (e.g., corrosion resistance, thermal conductivity, or tensile strength).

Precision Engineering: Ensuring exact dimensions and tolerances to guarantee proper assembly and performance.

Surface Finishing: Applying treatments like galvanization, powder coating, or polishing to enhance durability and appearance.

Testing and Inspection: Implementing quality control steps such as laser measurement, hardness testing, and stress analysis.

Meeting ISO, CE, or ASTM standards ensures that each part performs safely and efficiently under real-world conditions. High-quality Sheet Metal Parts ultimately reduce the need for rework, improve reliability, and build trust with end users.

How Are Global Trends Influencing the Sheet Metal Parts Market?

The global Sheet Metal Parts market is growing steadily, fueled by increasing industrial automation and the expansion of electric vehicles, consumer electronics, and infrastructure development.

Asia-Pacific—particularly China, Japan, and South Korea—dominates global production, thanks to advanced fabrication facilities and strong supply chain networks. Meanwhile, Europe and North America are investing heavily in custom precision sheet metal fabrication and sustainable production technologies.

The rise of digital manufacturing platforms is another key trend. These platforms allow clients to upload CAD files and receive instant production quotes, accelerating project timelines and enabling flexible, small-batch manufacturing.

What Does the Future Hold for Sheet Metal Parts Manufacturing?

The future of Sheet Metal Parts is closely tied to the progress of automation, artificial intelligence, and smart materials. In the coming years, we can expect:

AI-powered design optimization to reduce material waste.

3D metal printing integration with traditional sheet fabrication.

Lightweight composite-metal hybrids for next-generation vehicles and aircraft.

IoT-enabled monitoring systems that track part performance in real time.

As sustainability and performance demands rise, Sheet Metal Parts will continue to evolve—becoming lighter, stronger, and more precise than ever before.

Why Are Sheet Metal Parts the Cornerstone of Modern Industrial Innovation?

From smartphones to skyscrapers, Sheet Metal Parts form the structural and functional backbone of countless products. Their combination of precision, flexibility, and affordability makes them the ideal choice for manufacturers striving to balance performance with cost efficiency.

As industries embrace automation, customization, and environmental responsibility, Sheet Metal Parts will remain at the forefront of innovation—proving that even the thinnest layers of metal can build the strongest foundations for the future of technology and manufacturing.

Eng

Eng  中文简体

中文简体