Why Internal Thread Processing Is Crucial for Precision Engineering: Features, Applications, and Advantages of Cone Internal Thread Processing?

2025.08.20

2025.08.20

Industry News

Industry News

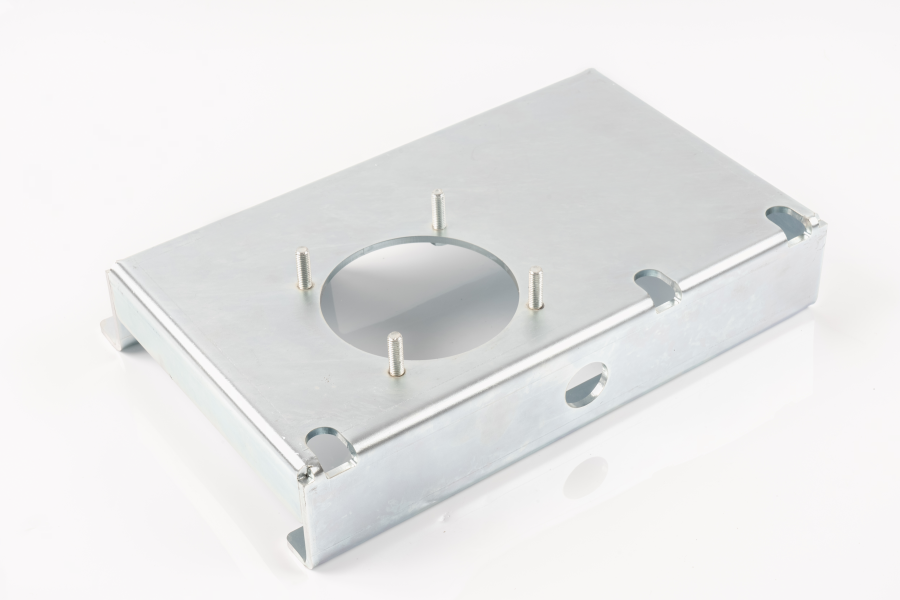

In modern manufacturing, Internal Thread Processing has become a fundamental technique used to create threaded holes in components, ensuring precise assembly and secure fastening. As industries increasingly demand high-precision mechanical parts, Cone Internal Thread Processing plays a vital role in producing reliable and durable threaded components.

Definition and Key Features

Internal Thread Processing refers to the process of cutting, tapping, or forming threads inside a pre-drilled hole to create a precise mating surface for bolts, screws, or fasteners. Cone Internal Thread Processing specifically applies threading techniques to tapered or conical surfaces, often used in hydraulic, pneumatic, and high-pressure systems.

Key features of Cone Internal Thread Processing include:

High Precision Machining: The process ensures tight tolerances, creating threads that fit perfectly with corresponding external threads, which is critical for applications requiring leak-proof connections or high mechanical strength.

Versatility Across Materials: Suitable for metals such as stainless steel, aluminum alloys, brass, and even high-strength polymers, enabling internal threads in a wide range of industrial components.

Enhanced Thread Strength: Using advanced cutting tools and controlled processing parameters, high-strength internal threading ensures the threads can withstand torque, vibration, and high-pressure conditions without failure.

Efficient Production: Modern CNC machines and specialized tapping equipment allow machine internal thread cutting to be fast, repeatable, and reliable, minimizing downtime and increasing manufacturing efficiency.

Surface Quality and Durability: Properly executed internal thread processing produces smooth, burr-free threads with excellent contact surface quality, enhancing both assembly reliability and longevity.

Compatibility with Multiple Fasteners: Tapered or conical threads produced through cone internal thread processing provide secure fittings for hydraulic fittings, pipe connections, and precision mechanical assemblies.

Technical Parameters

The performance and quality of internal thread processing can be evaluated through several key parameters, which ensure the threads meet industrial standards and function reliably. The following table highlights the main specifications:

| Performance Parameter | Description |

|---|---|

| Thread Type | Metric, Unified, BSPT, NPT, Conical (tapered) threads |

| Material Compatibility | Stainless steel, carbon steel, aluminum, brass, high-strength alloys |

| Thread Accuracy | Tolerance class 6H or higher, ensuring tight fit and precision |

| Surface Finish | Smooth, burr-free, high-contact surface quality |

| Hardness of Threads | Maintains structural integrity under high torque and load |

| Thread Length | Customizable based on component design and application |

| Durability | High-strength internal threads suitable for repeated assembly and disassembly |

| Corrosion Resistance | Compatible with coated or treated materials for harsh environments |

| Application | Automotive, hydraulic systems, pneumatic systems, industrial machinery |

These technical parameters emphasize why internal thread processing is essential for components requiring high precision and reliability.

Application Scenarios

Internal Thread Processing is widely applied across various industries, providing secure and durable threaded connections in critical systems:

Automotive Manufacturing: Ensures precise internal threads for engine components, gear assemblies, and suspension systems, contributing to vehicle safety and performance.

Hydraulic and Pneumatic Systems: Cone internal thread processing is often used for hydraulic fittings, adapters, and connectors, providing leak-proof, high-pressure resistant connections essential for fluid control systems.

Aerospace and Aviation: Critical components such as turbine assemblies, landing gear parts, and airframe structures require precision internal threads to maintain structural integrity under high stress.

Industrial Machinery and Equipment: Machine tools, pumps, and heavy-duty manufacturing equipment rely on durable internal threads to ensure stability, vibration resistance, and long-term performance.

Pipe and Tube Fittings: Tapered internal threads produced through internal thread machining allow tight, sealed connections in plumbing, gas pipelines, and chemical transport systems.

Construction and Heavy Equipment: Internal threads in high-strength steel components enable secure assembly in cranes, bulldozers, and other heavy machinery where safety and load-bearing capacity are crucial.

Advantages of Cone Internal Thread Processing

Several benefits make internal thread processing indispensable in precision manufacturing:

Enhanced Load-Bearing Capacity: High-quality internal threads produced through cone internal thread processing can withstand greater torque and pressure, reducing the risk of failure in mechanical assemblies.

Improved Assembly Reliability: Precision threads ensure tight, stable connections, minimizing loose fittings, leaks, and operational disruptions.

Durability in Harsh Environments: Threads generated with proper machining techniques resist wear, corrosion, and repeated assembly cycles, making them suitable for industrial and high-pressure applications.

Time and Cost Efficiency: Modern machine threading techniques reduce manual labor, increase throughput, and ensure consistent quality across batches, lowering production costs.

Wide Material Compatibility: Applicable to metals and polymers, including stainless steel, brass, aluminum, and high-strength alloys, providing flexibility across multiple industries and component types

Eng

Eng  中文简体

中文简体