Why Are Stamping Metal Parts Becoming Essential in Modern Manufacturing?

2025.08.27

2025.08.27

Industry News

Industry News

What Are Stamping Metal Parts?

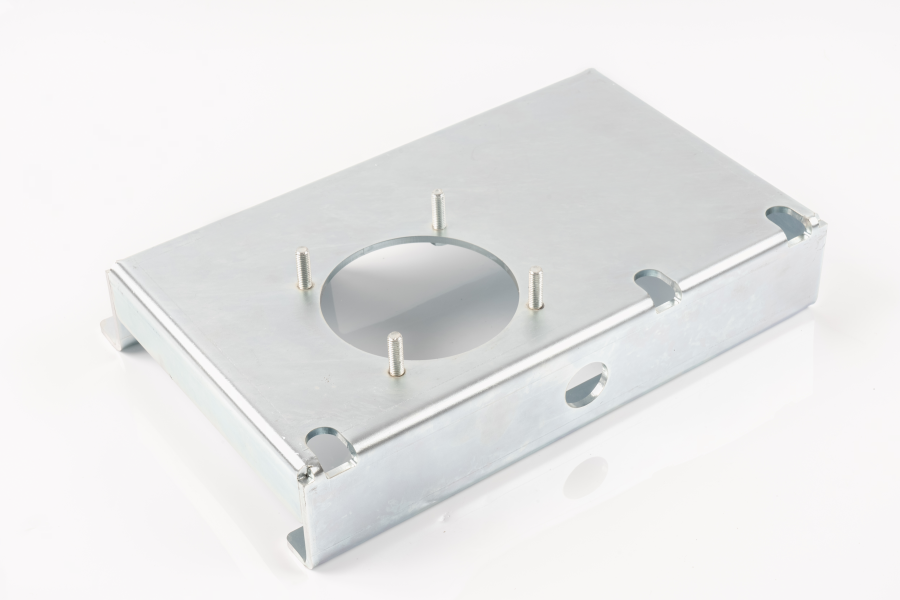

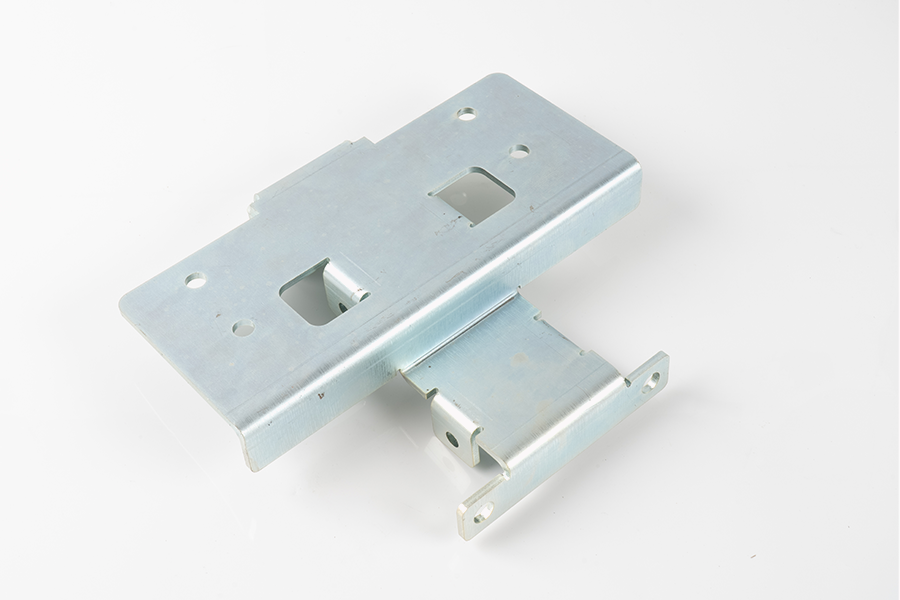

Stamping metal parts refers to the process of using high pressure to shape or cut metal sheets into specific shapes or forms. This is achieved through a metal stamping press that exerts force on a metal sheet, pushing it into a mold to create parts for a wide range of industries. These parts can be anything from simple washers to complex car body panels. Stamping metal parts is a highly efficient, cost-effective, and precise process, making it an essential technique in modern manufacturing.

Typically, materials used in metal stamping include steel, aluminum, brass, and copper, with stainless steel being a particularly popular choice for parts that require high durability and resistance to corrosion.

Why Are Stamping Metal Parts Essential for Modern Manufacturing?

There are numerous reasons why metal stamping has become a key technology in modern production. Let’s break down some of the major advantages:

High Precision and Consistency:

One of the main reasons metal stamping is so widely adopted is its ability to produce highly precise and consistent parts. In industries where tight tolerances are required, such as the automotive and electronics sectors, stamping metal parts ensures that each piece meets exact specifications. This is crucial for maintaining the performance, safety, and quality of products.

Whether you're producing components for consumer electronics, automotive assemblies, or medical devices, metal stamping ensures uniformity across high-volume production runs.

Cost-Effective and Scalable Production:

Another significant benefit of stamping metal parts is its cost-effectiveness. Once a metal stamping die is created, large volumes of parts can be produced quickly and at a relatively low cost. Metal stamping eliminates many of the costs associated with traditional machining processes, such as waste and labor. Additionally, since parts can be produced in large quantities, manufacturers can benefit from economies of scale, reducing the per-unit cost as production volume increases.

This makes metal stamping ideal for high-volume manufacturing, such as in the automotive industry, where thousands of parts need to be produced with precision and at a low cost.

Wide Range of Applications:

The versatility of metal stamping is another factor contributing to its popularity. This process can be used to create a wide range of products, including automotive components, appliance parts, electronic housings, industrial tools, and more. Stamped metal parts can be used in industries as diverse as aerospace, electronics, construction, and consumer goods, making it one of the most adaptable manufacturing methods available.

Stamping metal parts can be customized to meet specific requirements for strength, appearance, and functionality, making it suitable for both functional and decorative components.

Comparing Stamping Metal Parts with Other Manufacturing Techniques

While metal stamping is a popular choice for many industries, it is important to compare it with other manufacturing methods to understand its advantages better. Below is a comparison table between metal stamping and other common manufacturing techniques, such as die casting and machining:

| Feature/Dimension | Stamping Metal Parts | Die Casting | Machining |

| Production Speed | Fast, ideal for mass production | Moderate, slower than stamping | Slow, more labor-intensive |

| Material Waste | Low material waste | Moderate waste due to excess material | High material waste |

| Precision | High precision, tight tolerances | Moderate precision | Very high precision, but slower |

| Cost Efficiency | Very cost-effective for high volume | High initial setup cost, suitable for low-volume production | High cost due to slower production |

| Strength | High strength with proper die design | Good for non-ferrous metals | Suitable for precision machining but often requires additional processes |

| Versatility | Suitable for many industries and applications | Best for casting complex shapes | Best for custom, one-off parts |

As seen in the comparison table, metal stamping is faster, more cost-effective, and suitable for high-volume production compared to die casting and machining. However, machining provides superior precision, especially for small, complex parts.

Key Applications for Stamping Metal Parts:

Due to its precision and versatility, stamping metal parts is used in a wide array of industries. Here are some of the primary applications:

Automotive Industry:

In the automotive industry, metal stamping is essential for producing body panels, brackets, and other structural components. These parts must meet high-strength requirements and withstand heavy usage over time. The precision of stamping metal parts ensures that each part fits perfectly, reducing the need for additional processing and minimizing waste.

Electronics:

The electronics industry relies on stamping metal parts for manufacturing components like circuit boards, connectors, and housing parts. The high precision of metal stamping ensures that each component fits exactly as needed in the final assembly.

Aerospace and Defense:

In the aerospace and defense industries, metal stamping is used to create high-performance components that must meet strict safety standards. Parts like aircraft components, fasteners, and electrical connectors benefit from the strength and durability of stamped metal parts, ensuring that they perform reliably in demanding environments.

Medical Devices:

Metal stamping is widely used to produce components for medical devices. Durability and precision are paramount in this sector, and stamped metal parts meet these demands for products like surgical tools, orthopedic implants, and medical instruments.

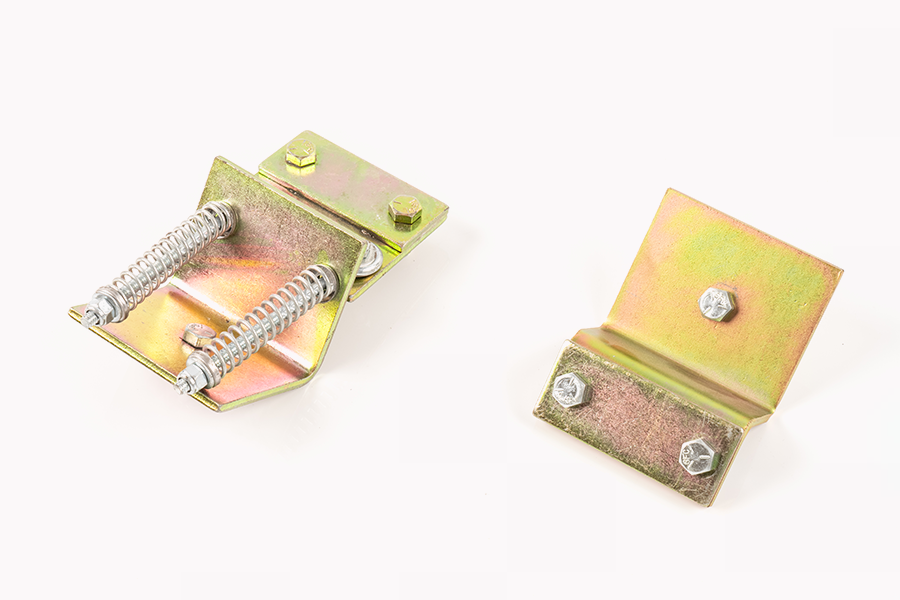

Consumer Products:

Stamped metal parts are also used in consumer products, including household appliances, furniture, and other durable goods. From handles and hinges to screws and brackets, metal stamping offers a cost-effective solution for producing small, high-quality parts that are essential to daily life.

Eng

Eng  中文简体

中文简体