How Are Sheet Metal Parts Transforming Manufacturing Processes Across Industries?

2025.09.03

2025.09.03

Industry News

Industry News

Sheet metal parts are an integral component of modern manufacturing processes, providing durability, precision, and versatility in industries ranging from automotive to aerospace. As the demand for high-performance, cost-effective, and lightweight components grows, sheet metal fabrication continues to evolve, offering new opportunities for innovation in production.

What Are Sheet Metal Parts?

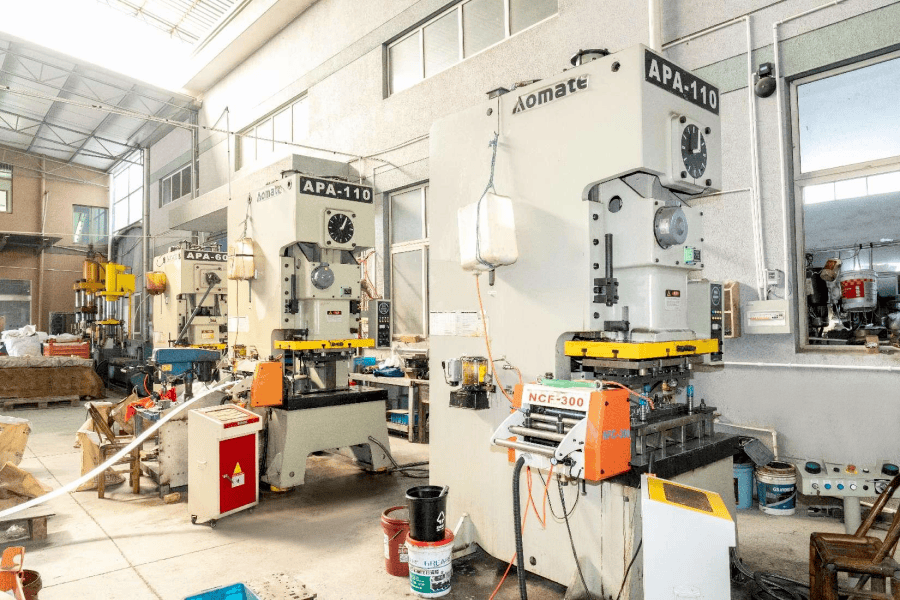

Sheet metal parts refer to components made from thin sheets of metal that are shaped, cut, and formed into the desired shape using processes such as punching, cutting, bending, and stamping. These parts are widely used in industries such as automotive, aerospace, electronics, and construction, due to their ability to be manufactured quickly, with high precision and at a lower cost compared to traditional machining.

Sheet metal is typically available in a variety of metals, including aluminum, stainless steel, carbon steel, brass, and copper, offering manufacturers flexibility in material selection based on the required performance, strength, and environmental considerations.

Key Features of Sheet Metal Parts:

-

Durability: Able to withstand high stress and weight while maintaining structural integrity.

-

Precision: Manufactured with high accuracy for tight tolerances and smooth finishes.

-

Versatility: Suitable for a wide range of applications, from automotive panels to electronic housings.

-

Lightweight: A cost-effective way to create strong, yet lightweight components for various industries.

-

Cost-Effective: Sheet metal parts are relatively inexpensive to produce, making them ideal for high-volume manufacturing.

Applications of Sheet Metal Parts

1. Automotive Industry

In the automotive industry, sheet metal parts are used in nearly every aspect of vehicle manufacturing, from body panels to structural components. Automotive sheet metal parts are designed for durability and strength, while also being lightweight to enhance fuel efficiency. These components are formed using processes like stamping and deep drawing to create complex shapes and high-strength parts. The use of aluminum and steel sheets in automotive applications is particularly important for producing body panels, engine parts, and interior components, providing a balance between strength and weight.

2. Aerospace Industry

The aerospace industry relies heavily on sheet metal parts for aircraft structures, including fuselage panels, wings, and frames. Due to the high performance and safety requirements in aerospace, these parts must be made from materials such as aluminum alloys and titanium. Aerospace sheet metal parts must meet stringent standards for strength, weight, and fatigue resistance. The manufacturing of these parts typically involves advanced techniques like laser cutting and hydroforming to meet the precision and performance standards required in aerospace applications.

3. Electronics and Consumer Goods

Sheet metal parts are also essential in the electronics industry, where they are used for enclosures, frames, and heat sinks. The electronics industry needs metal components that provide protection for sensitive internal parts while also offering heat dissipation capabilities. Sheet metal enclosures are particularly valuable for creating durable housings for devices like computers, power supplies, and mobile phones. The versatility of sheet metal parts enables the design of custom enclosures that protect electronic circuits from external environmental factors such as dust, moisture, and impact.

4. Construction and Infrastructure

In the construction industry, sheet metal parts are used for structural elements, roofing, siding, and facades. Metal roofing panels, for instance, offer long-lasting protection against the elements and are increasingly used in both residential and commercial buildings. The construction industry relies on galvanized steel and aluminum sheet metal for various applications such as framing, reinforcement, and exterior coverings. Sheet metal components are also used in HVAC systems, ducts, and insulation products, helping to improve building performance and energy efficiency.

Advantages of Sheet Metal Parts

1. Cost-Effective Manufacturing

One of the primary reasons sheet metal parts are favored across industries is their cost-effectiveness. The process of fabricating sheet metal is generally more affordable than other methods of manufacturing, such as casting or machining. This makes sheet metal parts an attractive choice for high-volume production, where keeping costs down without sacrificing quality is crucial.

2. Design Flexibility

Sheet metal fabrication offers a high degree of design flexibility, allowing for the production of custom parts that meet specific size, shape, and strength requirements. From simple brackets to complex panels with intricate patterns, sheet metal can be easily shaped into the desired form using techniques like stamping, bending, and welding. Additionally, sheet metal parts can be adapted for various surface finishes, from smooth and polished surfaces to textured and embossed finishes, giving designers a broad range of possibilities.

3. Strength-to-Weight Ratio

Another key benefit of sheet metal parts is their excellent strength-to-weight ratio. Metals like aluminum and steel offer a high level of strength while maintaining a relatively low weight, which is crucial for industries like automotive and aerospace, where reducing weight can lead to increased fuel efficiency and performance. The ability to produce lightweight yet strong parts through sheet metal fabrication is one of the reasons why it is so widely used in manufacturing.

4. Recyclability

With the growing emphasis on sustainability, the recyclability of sheet metal parts is an important factor for many industries. Steel, aluminum, and other metals used in sheet metal manufacturing can be easily recycled, making these parts environmentally friendly. This not only reduces the overall environmental footprint but also helps manufacturers meet sustainability goals and adhere to environmental regulations.

How Does Sheet Metal Compare to Other Materials?

When considering materials for manufacturing, it's essential to compare sheet metal with other commonly used materials, such as plastic and composite materials. Below is a comparison of sheet metal with plastic and composite materials:

| Feature/Property | Sheet Metal Parts | Plastic Parts | Composite Materials |

| Strength | High strength, suitable for heavy-duty applications | Lower strength, suitable for lighter applications | High strength, depending on the type of composite |

| Weight | Moderate to heavy, depending on the material | Very light | Light to moderate, depending on the composite material |

| Durability | Excellent durability, resistant to impact | Lower durability, more prone to cracking | Excellent durability, resistant to wear and corrosion |

| Cost | Cost-effective for high-volume production | Generally lower initial cost | Higher cost due to material and manufacturing processes |

| Recyclability | Highly recyclable | Limited recyclability | Limited recyclability, varies by material type |

| Applications | Heavy-duty, high-performance sectors | Consumer goods, packaging | Aerospace, automotive, and structural applications |

Key Takeaways:

-

Sheet metal parts offer excellent strength, durability, and design flexibility, making them ideal for high-performance industries like automotive, aerospace, and construction.

-

Plastic parts are typically more cost-effective but lack the strength and durability of sheet metal.

-

Composite materials are stronger and more durable but come with a higher price point, making sheet metal a better option for many high-volume applications.

Eng

Eng  中文简体

中文简体