Why is Advanced Sheet Metal Processing the Backbone of High-Precision Manufacturing?

2026.02.12

2026.02.12

Industry News

Industry News

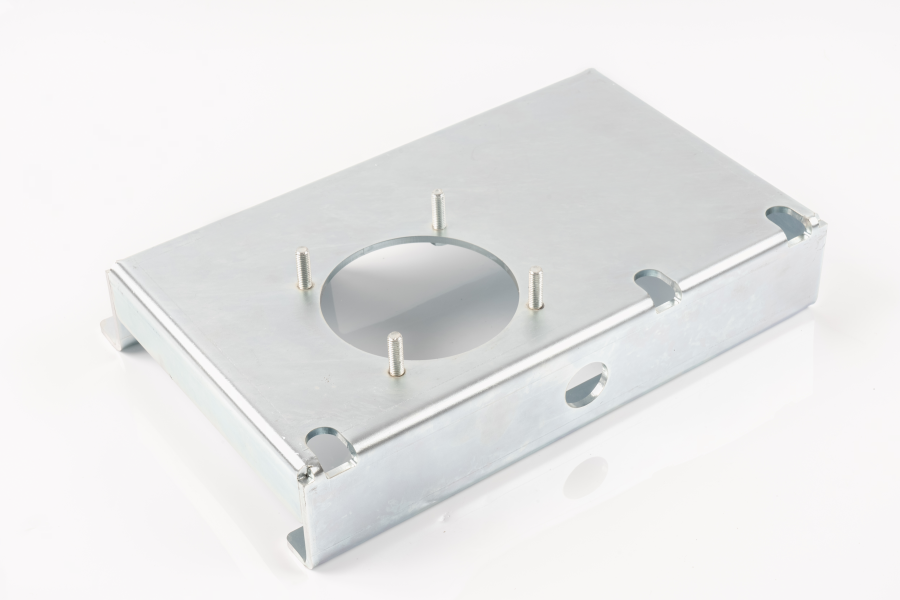

In the contemporary landscape of industrial production, the ability to transform raw materials into intricate, durable components is paramount. Sheet Metal Processing stands as a primary methodology for achieving this transformation. But what specific techniques allow for such a high degree of accuracy and repeatability? By utilizing a combination of mechanical force, specialized tooling, and computer-controlled systems, manufacturers can produce everything from simple brackets to complex aerospace housings.

The core of this process lies in the synergy between technology and craftsmanship. As a leading custom manufacturer, we emphasize the integration of highly skilled engineering teams with state-of-the-art machinery. This ensures that the transition from a flat sheet of metal to a precision-engineered component is seamless, cost-effective, and perfectly aligned with the client’s design specifications.

What Makes Sheet Metal Stamping the Ideal Choice for High-Volume Production?

When a project requires thousands or even millions of identical parts, which process offers the best balance of speed and quality? Sheet metal stamping is a manufacturing process in which a flat sheet of metal is placed into a stamping press and formed into the desired shape using specialized dies.

-

How does the stamping press operate? The press applies tremendous pressure to the die, which "stamps" the metal into shape. This method is ideal for high-volume manufacturing of durable and precise components while being cost-effective.

-

Can it maintain precision at scale? Yes. Because the dies are custom-made in an in-house tool and die shop, the consistency of the output is unparalleled. Our advanced sheet metal stamping services ensure that each part is made to your exact specifications, minimizing deviations across large production runs.

Below is a summary of the capabilities and technical parameters associated with our sheet metal stamping services:

|

Feature |

Specification / Capability |

|---|---|

|

Process Type |

Cold Forming / Sheet Metal Stamping |

|

Tooling |

In-house Tool and Die Shop |

|

Material Thickness |

0.5mm to 6.0mm (standard) |

|

Volume Capacity |

Prototype to High-Volume Production |

|

Secondary Operations |

CNC Bending, Welding, Finishing |

|

Industry Compliance |

Aerospace, Robotics, Automotive Standards |

|

Waste Management |

Engineered Scrap Minimization |

How Does CNC Bending Achieve Complex Geometries in Sheet Metal?

Not every component can be formed in a single stamping stroke. When a design requires intricate folds or non-linear shapes, how do we maintain the integrity of the part? As a specialized sheet metal stamping manufacturer, we utilize advanced CNC bending machines for specialized sheet metal bending of complex geometries.

-

Is the process automated? Modern CNC (Computer Numerical Control) bending allows for extreme precision. The operator programs the specific angles and sequence of bends, and the machine executes them with a high degree of repeatability.

-

What kind of shapes can be produced? We provide precise and efficient sheet metal bending services to meet the needs of your project, whether you require a simple angle or a complex, multi-step bend. This versatility allows us to support industries like robotics, where chassis and internal components often feature multi-dimensional facets.

Why is an In-House Tool and Die Shop Critical for Quality Control?

Many manufacturers outsource their tooling, but what are the risks of doing so? By maintaining an in-house tool and die shop, we ensure that the product you receive is exactly as per your design specifications.

When a die is created on-site, the engineering team has direct oversight. If a prototype requires a slight adjustment to improve the flow of metal during the stamping process, the change can be made immediately. This integration significantly reduces lead times and ensures that the final sheet metal processing result is optimized for both durability and aesthetic quality.

How Can Precision Engineering Minimize Material Usage and Scrap?

Efficiency in manufacturing isn't just about speed; it's about resource management. How do we provide consistent and cost-effective manufacturing processes while minimizing material usage and engineering scrap?

Through advanced nesting software and precision die design, we maximize the number of parts that can be extracted from a single sheet of metal. This "engineered scrap" reduction not only lowers the overall cost for the client but also contributes to a more sustainable manufacturing workflow. By choosing premium sheet metal stamping services, you are investing in a process that respects the raw material as much as the final design.

Can Sheet Metal Stamping Meet the Unique Needs of the Aerospace Industry?

The aerospace sector demands a level of precision that is often measured in microns. How does our team deliver components that exceed these expectations? From prototypes to high-volume production, we provide unparalleled quality and precision for critical aerospace parts.

Aerospace components must withstand extreme thermal and mechanical stress. Our sheet metal processing techniques ensure that the structural integrity of the metal is maintained during the stamping and bending phases. By avoiding micro-fractures and ensuring uniform thickness, we bring your designs to life with unmatched quality and expertise.

What Role Does a Highly Skilled Engineering Team Play in Custom Manufacturing?

Is the machine the only factor in a successful project? No matter how complex your project is, we are committed to meeting your requirements through the expertise of a highly skilled engineering team.

Our engineers work closely with clients during the Design for Manufacturing (DFM) phase. They analyze the blueprints to determine the most efficient way to stamp and bend the metal. This collaborative approach ensures that the "unparalleled quality" we promise is built into the process from the very first CAD drawing.

Is the Scalability of Sheet Metal Stamping Beneficial for Startups?

While stamping is known for high volumes, can it support the growth of a startup? We provide reliable and efficient services for every project, regardless of the initial order size.

For startups in the robotics or medical device fields, the ability to move from a handcrafted prototype to a stamped part is a significant milestone. Our services are designed to scale with your business. We provide the same level of precision-engineered components for a small batch of prototypes as we do for full-scale industrial production, ensuring that your product's quality remains consistent as your market grows.

How Do We Ensure Reliability in Complex, Multi-Step Bending Projects?

Some designs involve a sequence of bends that must be performed in a specific order to avoid part interference. How do our sheet metal bending services manage these complexities?

Our advanced equipment and experienced team ensure excellent results by simulating the bending sequence before the first piece of metal is even touched. This prevents errors, reduces waste, and ensures that even the most complex, multi-step bend is executed perfectly. Providing precise, reliable, and efficient services for every project is our baseline standard.

Why Should Industries Like Robotics Rely on Specialized Stamping Manufacturers?

Robotics is an industry defined by precision and durability. Why is a specialized sheet metal stamping manufacturer the best partner for this sector?

-

Lightweight Strength: Stamped components offer high strength-to-weight ratios, which is essential for mobile robots and robotic arms.

-

Complexity: The ability to combine stamping and CNC bending allows for the creation of internal frames that must hold multiple sensors and motors in exact alignment.

-

Consistency: In robotics, every millimeter counts. Our premium sheet metal stamping services are designed to meet these unique needs, ensuring that every chassis produced is a perfect match for the electronic components it will house.

How Does Modern Equipment Translate to Cost-Effectiveness?

Is "high quality" always synonymous with "high cost"? Actually, the use of advanced equipment often leads to lower unit costs.

Because our machines operate with high speed and precision, the labor cost per part is reduced. Furthermore, the accuracy of our CNC bending and stamping dies means that the rate of "reject" parts is near zero. This efficiency allows us to offer cost-effective manufacturing processes without compromising on the precision-engineered quality that our clients expect.

What is the Value of "Bringing Your Designs to Life" Through Expert Processing?

Ultimately, sheet metal processing is about realization. You have a design, and we have the tools to make it a reality. How do we ensure the final product exceeds expectations?

It comes down to our commitment to excellence at every stage. From the initial consultation with our engineering team to the final inspection of the stamped part, we are focused on unmatched quality and expertise. We don't just provide a service; we provide a partnership that ensures your precision-engineered components are ready for the most demanding applications in the world.

Eng

Eng  中文简体

中文简体