How Is Internal Thread Processing Revolutionizing Modern Manufacturing?

2025.09.17

2025.09.17

Industry News

Industry News

What Is Internal Thread Processing and Why Is It Important?

Definition of Internal Thread Processing

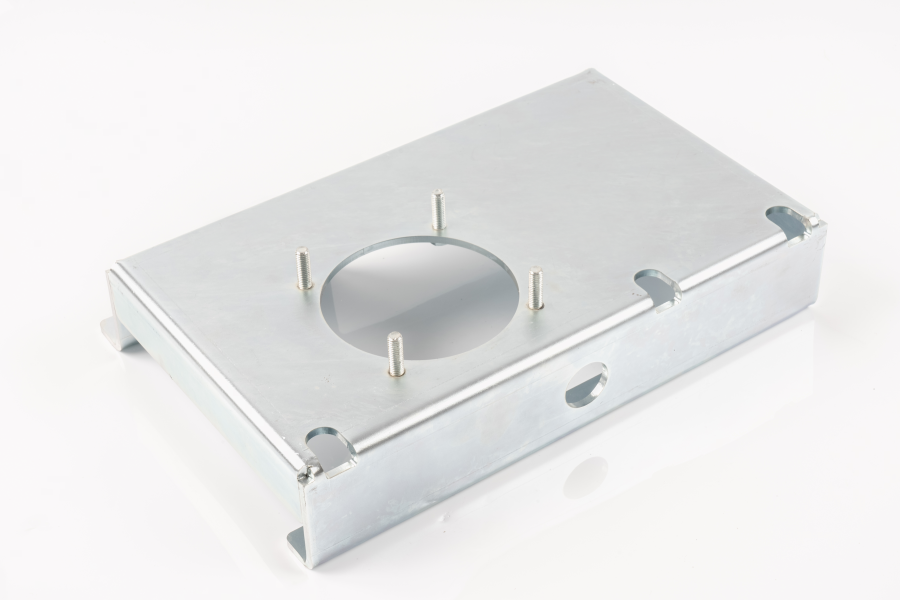

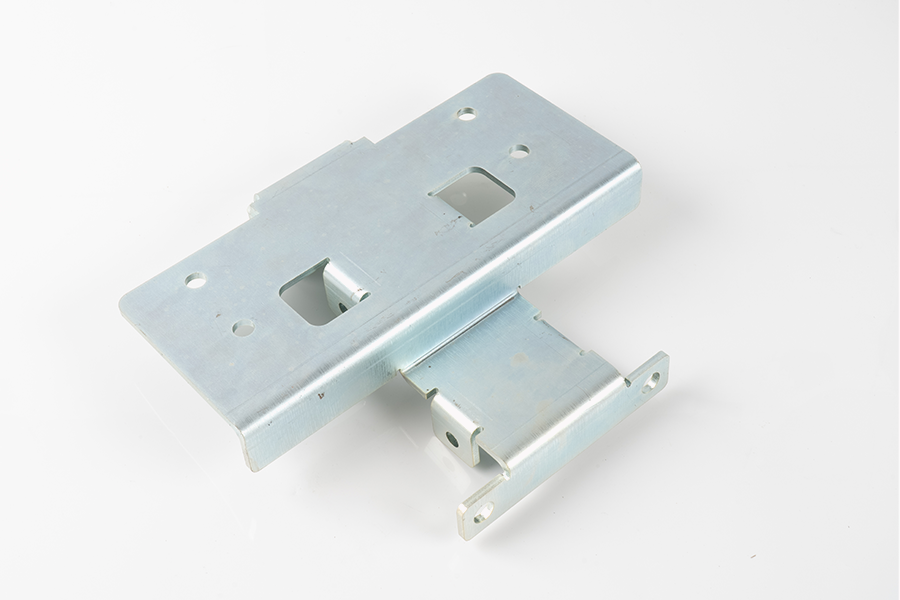

Internal thread processing refers to the manufacturing process used to create threads inside a hole or cavity of a component, allowing it to accept screws, bolts, or other threaded fasteners. This process typically involves tapping, which uses a cutting tool to form a helical thread pattern on the interior surface of a hole. Internal thread processing is essential for a wide variety of applications, from fastening mechanisms in mechanical assemblies to ensuring the proper fit and alignment of different components in systems.

Internal threads are commonly used in parts that require fastening to another component, such as machine housings, pipes, and connectors. Internal thread processing requires precision and accuracy to ensure that the threads are uniform, strong, and capable of holding the fastener securely under pressure or load. The process typically requires specialized machinery, such as tapping machines or CNC machines, to create high-quality threads with the correct size, pitch, and depth.

Role in Precision Machining and Manufacturing Industries

Internal thread processing plays a critical role in precision machining and manufacturing industries. It is used in the production of components that require reliable, secure fastening mechanisms for assembly and function. In industries like automotive, aerospace, and electronics, internal threads are essential for joining parts and ensuring proper alignment, load distribution, and mechanical stability.

The accuracy of internal thread processing directly impacts the quality and performance of the final product. For example, in the automotive industry, components such as engine blocks, transmission housings, and structural frames often require precisely manufactured internal threads to accommodate bolts and screws. The ability to consistently create threads with tight tolerances ensures that fasteners fit properly and remain secure, even under heavy stress or vibration.

In the aerospace industry, where safety and reliability are paramount, internal thread processing must meet stringent standards. Precision manufacturing techniques, including CNC machining and advanced threading tools, are employed to ensure that internal threads are consistently accurate and free from defects, preventing potential failures in critical systems.

Difference Between Internal and External Thread Processing

Internal thread processing differs from external thread processing in the way the threads are created and where they are applied. While internal threads are cut into the interior of a component, external threads are formed on the outer surface of a part. This distinction plays a significant role in how the components are used in the final assembly.

Internal Threads: These threads are formed inside a hole or cavity and are typically used to accept fasteners, such as screws or bolts. Common examples of parts requiring internal threads include nuts, valve bodies, and threaded inserts.

External Threads: External threads are created on the outside of a component, like on bolts, screws, and rods. These threads are designed to fit into pre-threaded holes or nuts, making them essential for secure fastening in mechanical assemblies.

The manufacturing methods for both internal and external threads can be similar, such as tapping for internal threads and turning or threading for external threads. However, internal threads require specialized equipment, such as tapping machines or CNC lathes with tapping functions, to accurately create threads within confined spaces. External thread processing, on the other hand, may require threading tools like dies or threading heads that work with the outer diameter of the material.

While both processes are critical to the functionality of many mechanical systems, the choice between internal and external thread processing depends on the design and assembly requirements. Both processes must be executed with precision to ensure proper fit, strength, and reliability in the finished components.

How Does Internal Thread Processing Compare to Other Threading Methods?

| Aspect | Internal Thread Processing | External Thread Processing |

| Application | Inside holes or cylinders | On rods, bolts, shafts |

| Precision | Higher tolerance, smaller components | Good for load-bearing external connections |

| Tools Used | Taps, thread mills, thread gauges | Dies, lathes, CNC thread cutting |

| Industries | Electronics, automotive, aerospace | Construction, heavy machinery, pipelines |

What Are the Challenges in Internal Thread Processing?

Handling Small Diameters and Deep-Hole Threading

One of the primary challenges in internal thread processing is handling small diameters and deep-hole threading. When working with small parts or components with deep cavities, it becomes difficult to ensure the threads are uniformly cut without affecting the integrity of the material. As the hole depth increases, it becomes harder to maintain consistent thread quality throughout the length of the hole. Specialized tools and equipment, such as deep hole taps, are required to address these challenges while maintaining high precision.

Tool Wear and Breakage Risks

Tool wear and breakage are common risks in internal thread processing, particularly when dealing with hard materials or high-speed machining operations. The cutting edges of the taps or thread mills gradually wear down over time due to the intense friction and heat generated during the threading process. This wear can affect the accuracy of the threads and may lead to tool failure or breakage, disrupting production. Manufacturers must frequently monitor tool condition and replace tools at the appropriate intervals to maintain thread quality and avoid unexpected downtimes.

Material Hardness Affecting Process Efficiency

The hardness of the material being threaded plays a significant role in the efficiency of the internal thread processing. Harder materials, such as stainless steel or titanium, require specialized tooling and slower cutting speeds to avoid premature tool wear. Additionally, these materials may produce more heat during processing, which can affect the tool's lifespan and the quality of the threads. The choice of the right tools and cutting parameters is critical to ensuring the threading process is both efficient and effective when working with hard materials.

Maintaining Accuracy in High-Volume Production

Maintaining consistent accuracy during high-volume production is a significant challenge in internal thread processing. When manufacturing large quantities of components, even minor deviations in thread quality can lead to defects and increased costs. The challenge lies in ensuring that every component meets the desired specifications despite potential tool wear, material variations, or environmental factors. Advanced machinery, such as CNC machines with real-time feedback systems, is essential for maintaining accuracy and minimizing variation in high-volume production environments.

How Is Technology Improving Internal Thread Processing?

CNC and Automated Threading Machines

Advances in CNC and automated threading machines have greatly improved the precision and efficiency of internal thread processing. These machines are equipped with advanced control systems that enable highly accurate and consistent thread cutting. CNC machines can automatically adjust cutting speeds and tool paths to accommodate different materials and thread profiles, reducing human error and ensuring optimal performance. Automation also enhances production rates, allowing manufacturers to meet high-demand needs while maintaining tight tolerances.

Coated Taps and Thread Mills for Longer Tool Life

To combat tool wear and extend tool life, many manufacturers now use coated taps and thread mills. These coatings, such as titanium nitride (TiN) or diamond-like carbon (DLC), help reduce friction and heat buildup during the threading process, allowing tools to last longer and maintain cutting performance. Coated tools are especially beneficial when working with harder materials, as they reduce the likelihood of tool breakage and help maintain thread quality over extended production runs.

Digital Monitoring Systems for Real-Time Precision

Digital monitoring systems are increasingly being integrated into internal thread processing machines to provide real-time precision. These systems use sensors and feedback mechanisms to continuously monitor factors like thread depth, pitch, and alignment during the threading process. This allows manufacturers to detect and correct deviations from specifications instantly, ensuring that the threads remain within tolerance throughout production. Digital systems can also automate adjustments to machining parameters, further enhancing process control and reducing human intervention.

Eco-Friendly Lubricants and Cooling Methods

Environmental concerns have led to the development of eco-friendly lubricants and cooling methods in internal thread processing. Traditional cutting fluids can be harmful to the environment, but newer, more sustainable lubricants are designed to provide the necessary cooling and lubrication without damaging the ecosystem. Additionally, advanced cooling techniques, such as minimum quantity lubrication (MQL), help reduce fluid usage and enhance the efficiency of the threading process while minimizing waste.

When Should Manufacturers Choose Internal Thread Processing Solutions?

For Components Requiring Compact, Precise Connections

Internal thread processing is ideal for components that require compact and precise connections. This includes applications where space is limited and a secure, reliable fastener is needed within a confined area. In industries such as electronics, automotive, and aerospace, internal threads are often used for compact assemblies that require precise and secure connections to ensure safety and functionality. Choosing internal thread processing in these applications ensures that fasteners fit securely, providing long-lasting durability and performance.

For Industries Where Safety and Reliability Are Critical

In industries like aerospace, automotive, and medical manufacturing, safety and reliability are paramount. Internal thread processing ensures that fasteners, such as bolts or screws, are securely held in place, reducing the risk of failures. Accurate internal threading is essential in high-stress environments where the integrity of connections can directly affect the safety of the system. Manufacturers should choose internal thread processing solutions in these industries to ensure that components are properly assembled and meet stringent safety standards.

For Large-Scale Production with Tight Tolerances

When producing large quantities of parts that require high precision, such as in mass manufacturing or high-volume industrial applications, internal thread processing is the ideal solution. Maintaining consistent thread quality across large production runs is crucial to prevent defects and ensure the integrity of the final product. By using advanced machines like CNC systems, manufacturers can produce large volumes of components with tight tolerances, reducing waste and improving overall efficiency.

What Is the Future of Internal Thread Processing?

AI-Driven Smart Machining Systems

The future of internal thread processing is expected to be heavily influenced by AI-driven smart machining systems. These systems use artificial intelligence to optimize cutting paths, adjust parameters in real-time, and predict tool wear. AI can also help detect issues in the threading process before they occur, reducing downtime and ensuring higher-quality threads. As AI technology continues to advance, internal thread processing will become even more automated and efficient, enabling manufacturers to achieve greater precision and productivity.

Additive Manufacturing Integration with Threading

Additive manufacturing (3D printing) is increasingly being integrated with traditional threading processes. This combination allows for the creation of complex parts with internal threads in one seamless process, reducing the need for separate machining steps. As 3D printing technology improves, it will likely become a more common method for producing components with internal threads, especially in industries where customized or small-batch parts are required.

Global Demand Growth in EVs, Aerospace, and Microelectronics

The global demand for components in industries such as electric vehicles (EVs), aerospace, and microelectronics is driving growth in internal thread processing. As these industries continue to expand, the need for precision parts with high-quality internal threads will increase. Manufacturers will need to adapt to these demands by adopting advanced threading technologies that ensure efficiency and consistency across a wide range of applications.

Sustainable Machining Practices and Energy Efficiency

Sustainability is becoming an increasingly important factor in manufacturing. The future of internal thread processing will see a continued focus on reducing energy consumption and minimizing the environmental impact of machining operations. Sustainable machining practices, such as energy-efficient machines, eco-friendly cutting fluids, and optimized production processes, will become standard in the industry. This shift towards sustainability will help manufacturers reduce their carbon footprint and contribute to a more environmentally responsible future.

Eng

Eng  中文简体

中文简体