Does the company have a standardized process for assembling fabricated assemblies?

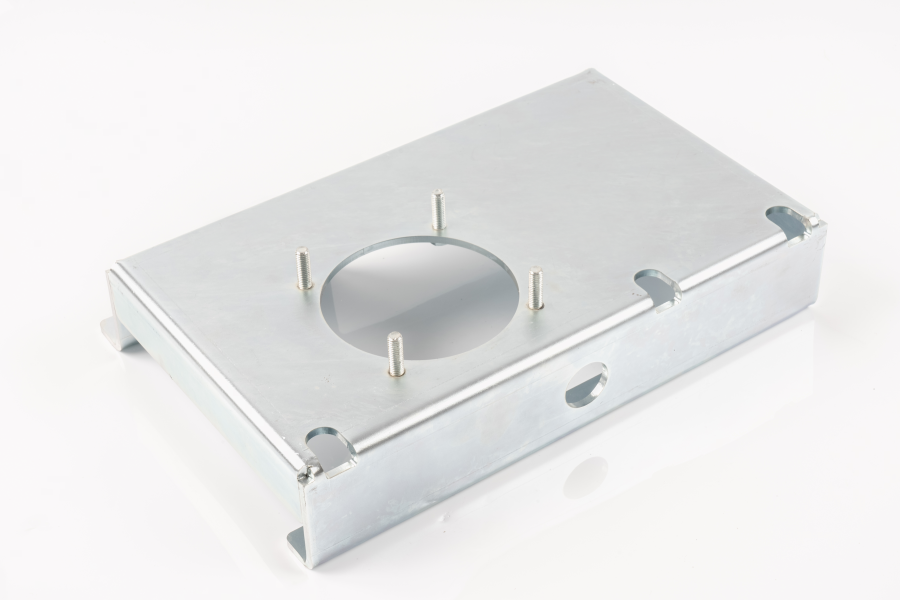

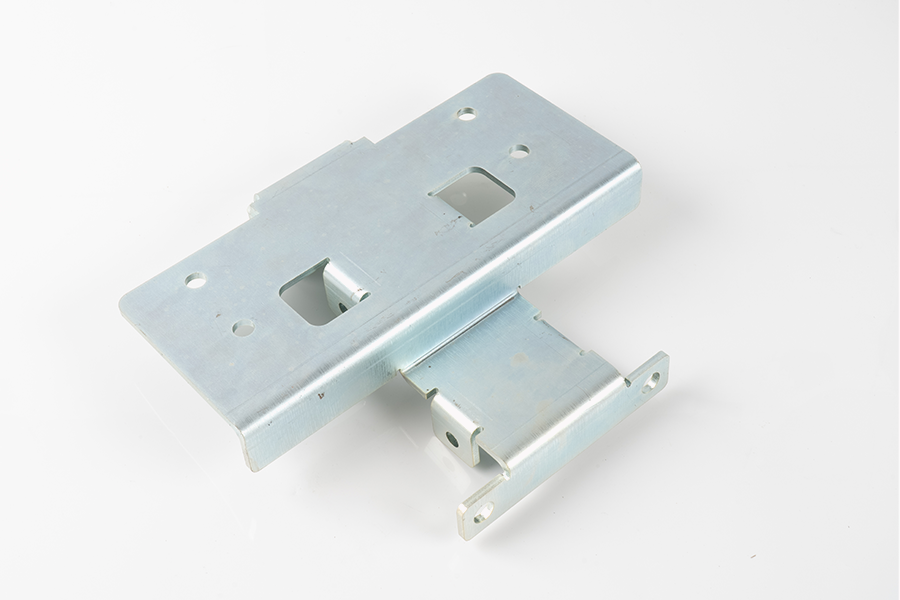

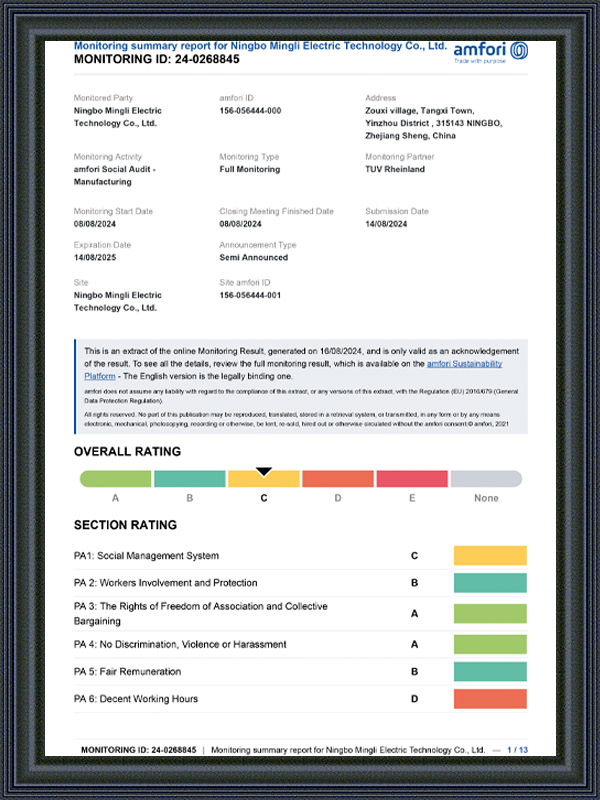

In the production process of fabricated assemblies, the establishment of standardized process flow is of great significance for ensuring product quality, improving production efficiency and reducing rework rate. Ningbo Mingli Electric Technology Co., Ltd. is well aware of this. In actual assembly operations, it always adheres to standardized and systematic processes as the basis, starting from multiple links, and building a production operation system that meets the development needs of the industry.

In the entire assembly process, the company first clearly divides each process by formulating detailed process documents. Each operator needs to undergo corresponding technical training and be familiar with assembly steps, operation standards and key control points. This not only improves the operator's operational proficiency, but also effectively reduces the quality risks caused by human errors. Before the assembly operation begins, the operation area will be prepared according to the process requirements, including the reasonable planning of tools, fixtures, and parts placement to ensure the smooth connection of the operation process.

In the component matching stage, the company has clear specifications for the installation sequence of parts, the way of applying torque, the way of gap control, etc., and sets the assembly process card in combination with product characteristics to ensure that the execution of each process meets the design requirements. In addition, in order to avoid scratches, deformation and other problems during operation, the assembly area is equipped with special flexible brackets and tooling to avoid direct contact with adverse effects on the surface or structure of the components.

For different types of fabricated assemblies, the company optimizes the process settings according to the complexity of the product structure and customer requirements. For example, in assembly projects where multiple materials are used together, process adaptability analysis will be carried out in advance to clarify which steps must be surface treated first and which nodes require buffer protection to reduce the probability of rework. The company also pays attention to process records. After each process is completed, there are operation records and initial inspection confirmations to facilitate quality traceability and data accumulation.

In the post-assembly inspection link, the company adopts a joint inspection method of manual and equipment. Detailed inspections are carried out on structural coordination, flexibility of moving parts, electrical connectivity and other aspects to ensure that the functions after assembly meet the design expectations. After the assembly is completed, the product is transferred to the finished product buffer, and the quality inspector conducts a final inspection according to the inspection specifications. After confirmation, the warehousing or packaging operations are carried out.

The company continuously summarizes production experience and introduces advanced technology and management concepts to continuously improve the standardized process. In the context of increasingly diversified order structures and more personalized customer needs, standardized processes do not mean rigidity, but rather operating standards based on flexible response and continuous improvement. Through standardized process flows, the company not only improves product consistency, but also enhances its ability to cope with batch and customized assembly projects, thereby better serving customers from different markets such as Europe, America, Southeast Asia, and the Middle East. Ningbo Mingli Electric Technology Co., Ltd. regards standardization as an important part of basic management, and promotes the steady improvement of assembly quality through institutional guarantees, technical support, and personnel training, providing customers with more reliable fabricated assemblies solutions.

How does the company control the surface integrity and assembly tolerance of fabricated assemblies so that they are not damaged?

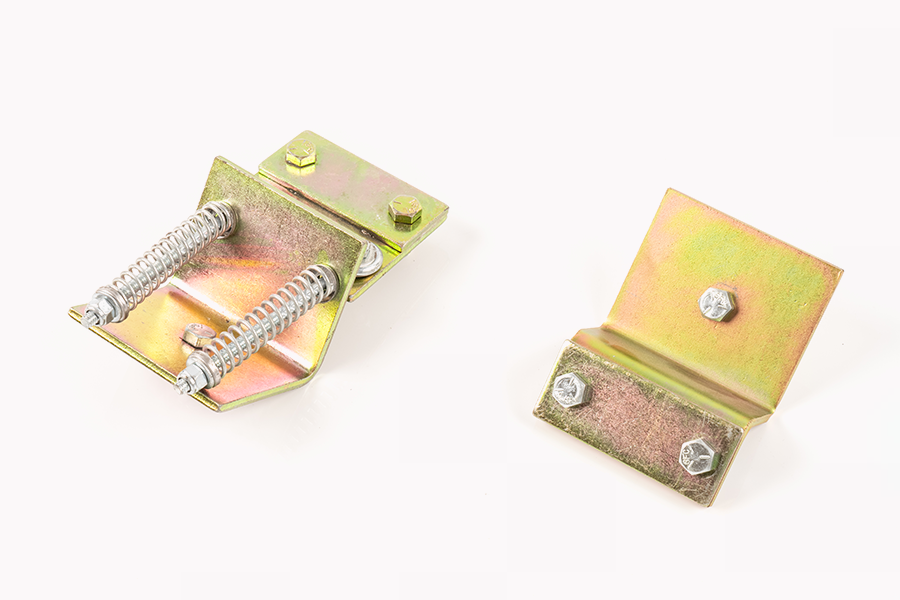

In the production process of fabricated assemblies, the control of surface integrity and assembly tolerances are important factors in ensuring product performance and appearance quality. Ningbo Mingli Electric Technology Co., Ltd. is well aware of this, so it has established a multi-level and multi-dimensional quality management system in the entire assembly process to ensure that each product meets the customer's requirements for surface quality and dimensional accuracy before delivery.

The company has set up strict inspection procedures in the storage of raw materials and parts. All components used for assembly must undergo pre-checking of surface quality and dimensional accuracy before entering the assembly workshop. Dimensional review and surface defect inspection are carried out through professional testing equipment such as calipers, micrometers, surface roughness meters, etc., to ensure that the parts meet the process requirements before they have entered the assembly process. This pre-mounting link provides reliable guarantees for subsequent assembly, avoiding the entry of unqualified parts into the work station, and reducing the possibility of surface defects and tolerance deviations from the source.

During the assembly process, the company attaches great importance to the influence of operating processes on surface quality and coordination accuracy. All staff involved in assembly receive system training to master key skills such as part docking, coordination adjustment, and torque control. In specific operations, the company has equipped a variety of soft tooling and protective pads to reduce direct contact between parts and fixtures, tools or other components, and effectively prevent surface damage such as abrasions and indentations. Especially when it comes to spraying, electroplating, anodizing and other treated parts, the assembly station will have clear sign reminders and special placement areas to avoid improper operation and damage to the surface treatment.

In order to control tolerance deviations during assembly, the company has established an intermediate inspection system in multiple key processes. It includes dimension retesting, matching gap verification and positioning consistency confirmation and other links, and dynamic monitoring of assembly accuracy is carried out through actual measured data. If the deviation is found to exceed the specified range, the subsequent operations will be immediately terminated and cause analysis and re-repair will be performed. This mechanism effectively avoids the layer-by-layer overlap of assembly deviations and ensures that the overall components meet design requirements.

After assembly is completed, the quality inspection department will conduct a comprehensive re-inspection of the product. It includes inspections of visible defects such as surface scratches, coating peeling, and depressions, as well as verification of the overall structure size and confirmation of coordination tolerances. Some components with complex structures or high requirements will also be arranged for multiple rounds of re-testing to enhance reliability. In the packaging process, the company chooses customized linings, anti-static bags or foam support materials according to the component type to further prevent surface or structural damage caused by vibration or extrusion during transportation.

The company also focuses on summarizing experience in production practice and continuously optimizing assembly processes and process parameters. The technical team will repeatedly verify and adjust the assembly sequence, connection method, tool selection and other links based on the product structure characteristics of different customers. If the customer has specific requirements, he can also assist in the formulation of targeted quality control standards and inspection plans to ensure that the final product meets its dual requirements for accuracy and appearance when delivered.

Eng

Eng  中文简体

中文简体