Does the company support customized sheet metal parts based on models or drawings provided by customers?

Since its establishment, Ningbo Mingli Electric Technology Co., Ltd. has always adhered to customer-oriented, continuously optimized production management processes, and improved product research and development capabilities. For sheet metal parts processing services, the company has strong customization capabilities, and can carry out directional development and production according to the models or drawings provided by customers to meet the personalized needs of different industries and different application scenarios.

In terms of sheet metal customization services, the company has an experienced technical team that is familiar with various processing techniques and structural design principles, and can quickly conduct feasibility analysis based on the three-dimensional model or two-dimensional drawing provided by the customer. The team confirms the rationality and operability of the product processing process through drawing review, structural disassembly, process simulation and other means, and formulates a scientific process plan based on the actual conditions of the production equipment, thereby effectively reducing the risk of trial production and improving processing efficiency.

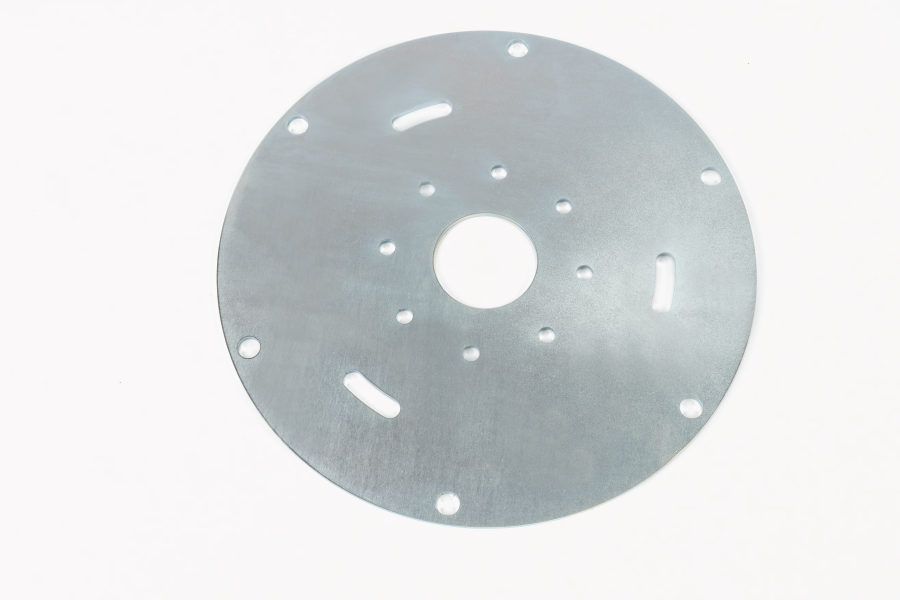

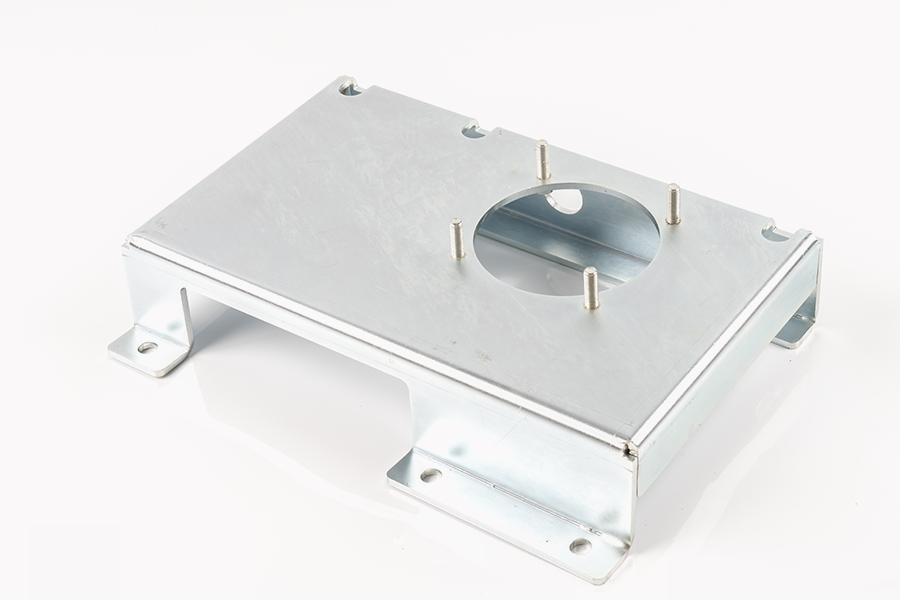

In actual operation, whether it is common laser cutting, CNC bending, or more complex welding, assembly and surface treatment, Mingli Electric can accurately execute according to the requirements of the drawings. The company is equipped with multiple automated equipment and has strong flexible production capabilities. It is suitable for multi-variety, small batch or large batch sheet metal customization tasks, especially for parts with high requirements for dimensional accuracy, geometric tolerance and structural matching.

During the sheet metal processing process, the company pays attention to maintaining full communication with customers. In the early stage of design, technicians will assist customers in optimizing structural details, improving production feasibility and controlling manufacturing costs; in the sample confirmation stage, customers can make further adjustment suggestions based on the actual objects to ensure that the final product is more suitable for practical applications; in the mass production stage, the company strictly implements the quality management system, and conducts item-by-item inspections on dimensions, appearance, strength, etc. to ensure that the product is consistent with the drawings or models.

In addition to processing capabilities, Mingli Electric also provides supporting material selection suggestions and surface treatment solutions. According to the working environment, service life and specific needs of sheet metal parts, different metal materials such as carbon steel, stainless steel or aluminum alloy are recommended, and combined with spraying, electroplating, anodizing and other processes to provide more comprehensive protection and appearance effects for the products. The company strives to take into account the actual use scenarios of customers in every link from source to delivery, so as to achieve a high degree of matching between processed parts and finished assembly.

In terms of export services, the company has the geographical advantage of being close to the port, which can quickly respond to the customized order needs of international customers and provide clear technical information and export documents. In addition, the company can also provide supporting services according to the packaging, transportation, labeling and compliance standards of foreign customers, reduce customers' communication and operating costs, and improve overall cooperation efficiency.

Ningbo Mingli Electric Technology Co., Ltd. is well aware that under the current trend of the manufacturing industry's continuous pursuit of diversification, personalization and high response speed, sheet metal customization services are not only the execution of drawings, but also a manifestation of comprehensive strength. Through continuous technical accumulation and customer collaboration, the company is committed to providing each customer with sheet metal parts solutions with more adaptability and implementation value, and promoting the common development of both parties in their respective markets.

Can the company meet customers’ requirements for special surface properties such as corrosion protection of sheet metal parts?

Ningbo Mingli Electric Technology Co., Ltd. has accumulated a relatively solid technical foundation in the field of sheet metal processing and can provide diversified surface treatment services according to the needs of different customers. Especially in the anti-corrosion performance of sheet metal parts, the company has relatively mature technology and supporting capabilities, and can design corresponding treatment solutions for different use environments and performance requirements to enhance the environmental adaptability and service life of the product.

Sheet metal parts are often faced with the test of complex environments such as moisture, acid, alkali, and salt spray in actual applications. Therefore, their anti-corrosion performance is often related to the overall functional stability and structural durability of the product. In daily production, Mingli Electric will provide reasonable protection measures for sheet metal parts based on customer drawings or instructions for use, combined with material properties and structural characteristics. Common treatment methods include spraying, electroplating, phosphating, anodizing and wire drawing. Different processes correspond to different metal materials and use conditions, and can effectively resist oxidation, rust and minor mechanical damage.

The company has an independent processing and surface treatment cooperation system, which can achieve good conditions for sheet metal parts before surface treatment through pre-treatment cleaning, degreasing, rust removal and other processes, thereby improving the bonding strength and uniformity of subsequent processes. For parts with higher requirements, the technical team will also recommend the use of multiple treatment processes, such as phosphating treatment to enhance the adhesion of the coating, and then electrostatic spraying or powder coating to further improve the overall corrosion resistance and decorative effect.

In sheet metal application scenarios with high appearance requirements such as electrical accessories and hardware, the company can also provide customized color, texture or surface finish solutions according to the customer's brand tone or product series style, so that the sheet metal parts are not only functional, but also have certain visual and tactile expressiveness, and enhance the overall product image. In addition, for some products that are used outdoors or in high temperature and high humidity environments for a long time, the company will give priority to recommending material combinations with stronger corrosion resistance, supplemented by anti-ultraviolet and anti-high temperature coatings, to extend the product's stable cycle from the design level.

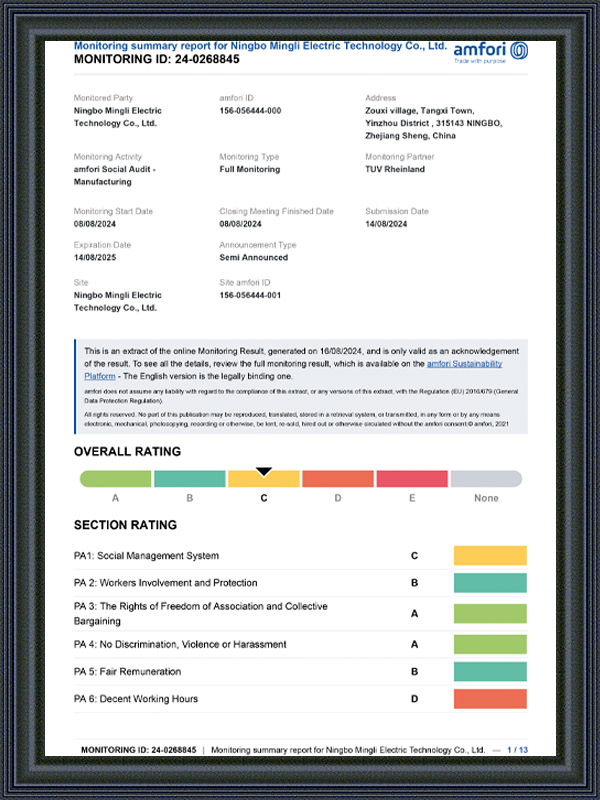

Mingli Electric implements a multi-link inspection mechanism in quality control, not only checking the size and structure of the finished product, but also sampling and testing the thickness, uniformity, adhesion and salt spray resistance of the surface treatment layer to ensure that each batch of sheet metal products can maintain a good condition during transportation, storage and use. The company is equipped with basic testing instruments and will also cooperate with qualified third-party testing agencies to provide test reports and compliance documents to assist customers in successfully completing the quality inspection or certification process in the terminal market.

In cooperation with foreign customers, the company is well aware that different countries and regions may have differences in environmental protection regulations and coating standards. Therefore, the technical team will fully communicate according to the requirements of the customer's market to ensure that the surface treatment plan complies with relevant regulations, such as low volatile organic compound emission standards or heavy metal control standards. Such preliminary communication and solution preparation will help customers put the product into use or sell it with more confidence.

Ningbo Mingli Electric Technology Co., Ltd. can provide customers with a more comprehensive surface protection solution for sheet metal parts, covering anti-corrosion, anti-oxidation, anti-fingerprint and high temperature resistance. By continuously optimizing the process, strictly controlling production quality and paying attention to actual application scenarios, the company is committed to helping customers improve the functionality and durability of their products and provide more reliable sheet metal parts support for various industrial applications.

Eng

Eng  中文简体

中文简体