Does the company regularly verify the dimensional consistency and stability of stamped metal parts?

Since its establishment, Ningbo Mingli Electric Technology Co., Ltd. has always adhered to the concept of strict control of product quality, especially in the production process of stamped metal parts, and has always regarded dimensional consistency and stability as one of the core quality control indicators. The company has established a systematic quality monitoring mechanism in daily production to ensure that each batch of products meets customer requirements and international standards in terms of dimensional control.

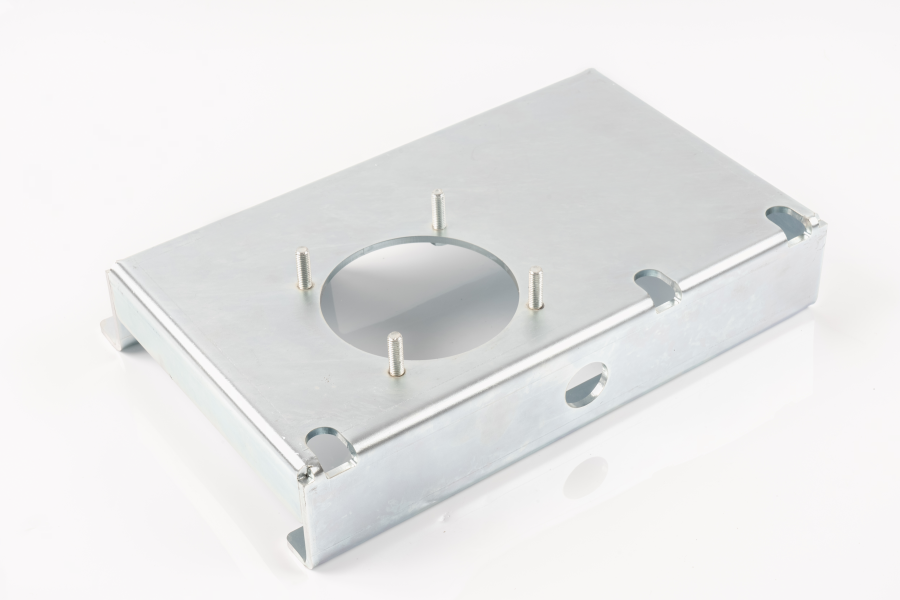

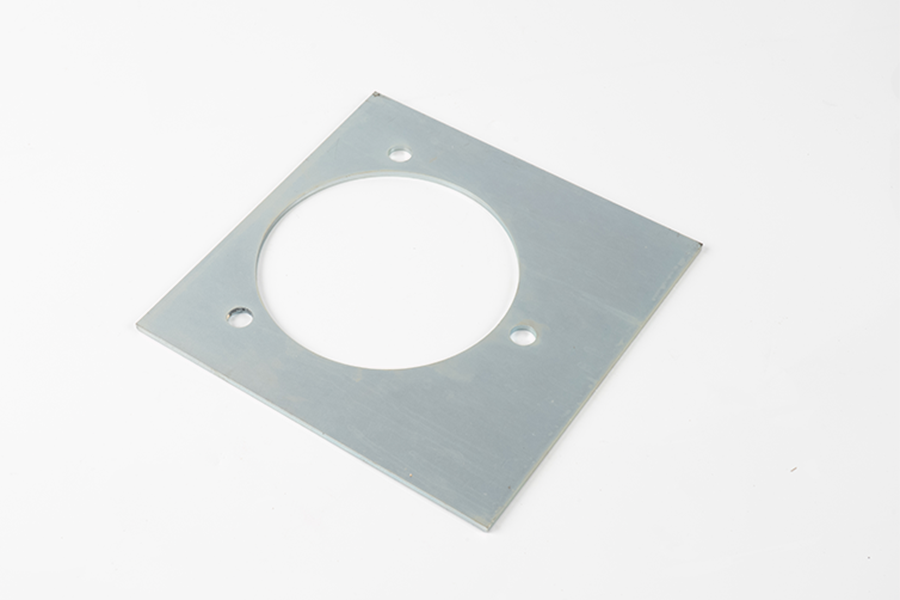

In the production process of stamped metal parts, dimensional control is the key link to determine whether the product is qualified. Slight deviations in size may directly affect the accuracy and performance of subsequent assembly. Therefore, the company attaches great importance to process control and data monitoring in the production process. Before production, technicians will conduct detailed process analysis based on customer drawings or samples, and formulate reasonable process parameters to ensure that the stamping equipment reaches a stable technical state during operation.

In order to further ensure the dimensional consistency of stamped parts, the company is equipped with a variety of measuring and testing equipment, including high-precision calipers, depth gauges, gauge blocks, projectors, surface finish meters, etc., which can measure the key dimensional parameters of products in real time. In actual operation, inspectors will conduct interval inspections on products at each stage according to the principle of random inspection of production batches, not only checking key dimensions, but also paying attention to important indicators such as corner flatness, hole position accuracy, bending angle, etc., striving to control the error within a reasonable range.

In addition to random inspections, Mingli Electric has also established a periodic verification mechanism. Especially when the mold is used frequently, the stamping mold will be evaluated for wear and size review to ensure that the mold accuracy is not affected. After the product batch is changed or the customer's requirements are changed, the company will also organize the first piece confirmation, and confirm the stability and consistency of the size through comprehensive measurement and comparison of the samples to avoid deviations in mass production.

The company advocates the concept of full participation in quality control. From front-line operators to quality departments to management, each position bears corresponding quality control responsibilities. Production operators need to confirm the status of molds, materials and equipment before the start of each shift. If any abnormality is found during the process, it will be reported immediately; quality inspectors are responsible for operating against the inspection standards and establishing data records to form a complete traceability system; management personnel conduct trend analysis and process improvements based on inspection data to continuously improve the consistency control level of products.

In order to enhance customer confidence, the company regularly organizes internal quality audits and accepts irregular inspections by third-party organizations. Before delivery, each batch of stamped metal parts must pass the final inspection procedure to ensure that all products meet export standards and customer contract requirements in terms of size, strength and appearance.

Ningbo Mingli Electric Technology Co., Ltd. has accumulated rich practical experience in ensuring the dimensional consistency and stability of stamped metal parts with its solid quality management system and rigorous production process. This not only provides customers with reliable products, but also wins the trust and recognition of customers from many countries and regions. By continuously optimizing the inspection process and improving employees' quality awareness, the company will continue to provide compliant and high-standard stamped metal parts products to the global market.

How does a company package stamped metal parts for export to prevent oxidation, scratching or deformation?

Ningbo Mingli Electric Technology Co., Ltd. always adheres to the rigorous and pragmatic packaging management principles in the export and transportation of stamped metal parts, striving to effectively prevent product oxidation, scratches and deformation during the logistics process, and ensure that the products are delivered to customers safely and intact. For different metal materials and product structures, the company has formulated a highly targeted packaging strategy to ensure that the products can maintain good physical condition and surface quality during long-distance transportation and multiple handling.

In view of the characteristics of stamped metal parts that are easily affected by moisture and oxidation, the company will give priority to moisture-proof materials for preliminary coating in the packaging process, such as anti-rust paper, moisture-proof film, etc. These materials can isolate moisture in the air to a certain extent, reduce the direct contact between the product surface and oxygen and moisture, and thus delay the occurrence of oxidation reactions. For some special materials or products with high anti-oxidation requirements from customers, oil coating will also be used to form a thin protective film to increase the protective effect.

In terms of preventing scratches, the packaging process adopts the method of separate packaging or interlayer packaging to avoid direct contact between products and friction. Normally, stamped metal parts are wrapped piece by piece with foam, bubble bags or pearl cotton, and then uniformly packed into outer packaging boxes with partitions or liners. This can not only play a buffering role, but also effectively avoid surface scratches caused by vibration or collision during transportation.

In terms of preventing deformation, the company attaches great importance to the stability of products during packing and stacking. Stamping parts will be reasonably arranged and reinforced before packing. If necessary, thickened cardboard, wooden boxes or plastic boxes will be used for support to ensure that the overall structure has sufficient compressive strength. During container shipping, the company will arrange professionals to fix and reinforce the products to avoid deformation of the products due to bumps, collisions or extrusions during transportation.

In view of the transportation characteristics of exports to Europe, America, Southeast Asia, the Middle East and other regions, the company will also formulate more suitable packaging solutions according to the climate, transportation time and customs clearance requirements of the destination. For example, for areas with humid climate or long cross-sea transportation time, moisture-proof and rust-proof measures will be strengthened; for routes with frequent transit and frequent loading and unloading, the strength of the outer box will be increased to improve impact resistance.

The company pays attention to label management during the packaging process. The product name, quantity, specifications, customer information and transportation direction are clearly marked on the outside of each box of products, which is convenient for rapid identification and sorting during transportation, and also convenient for customers to check and inspect when receiving the goods. For some precision stamped metal parts, the company will also provide neutral packaging or customized packaging services according to customer needs to meet the customer's sales and brand display needs in the local market. Ningbo Mingli Electrical Technology Co., Ltd. has always believed that export transportation is not only a physical process of product circulation, but also a comprehensive reflection of corporate image and service capabilities. Through scientific packaging design, standardized operating procedures and strict quality control, the company continues to improve the stability and reliability of stamped metal parts in the export transportation link, ensuring that each product can reach global customers in an appropriate way and safely, helping customers to smoothly deliver and continue to operate in the terminal market.

Eng

Eng  中文简体

中文简体