Can the company provide integrated processing services for high precision stamping parts?

Ningbo Mingli Electric Technology Co., Ltd. has been committed to providing customers with comprehensive high-precision stamping parts processing services. Based on the stamping process, the company can not only complete basic metal stamping, but also provide integrated follow-up processing services to ensure that each part can meet the specific needs of customers. Through years of technical accumulation and equipment investment, the company has been able to provide integrated solutions in the field of high-precision stamping, covering the entire process from material selection, preliminary stamping processing to surface treatment, assembly and final product delivery.

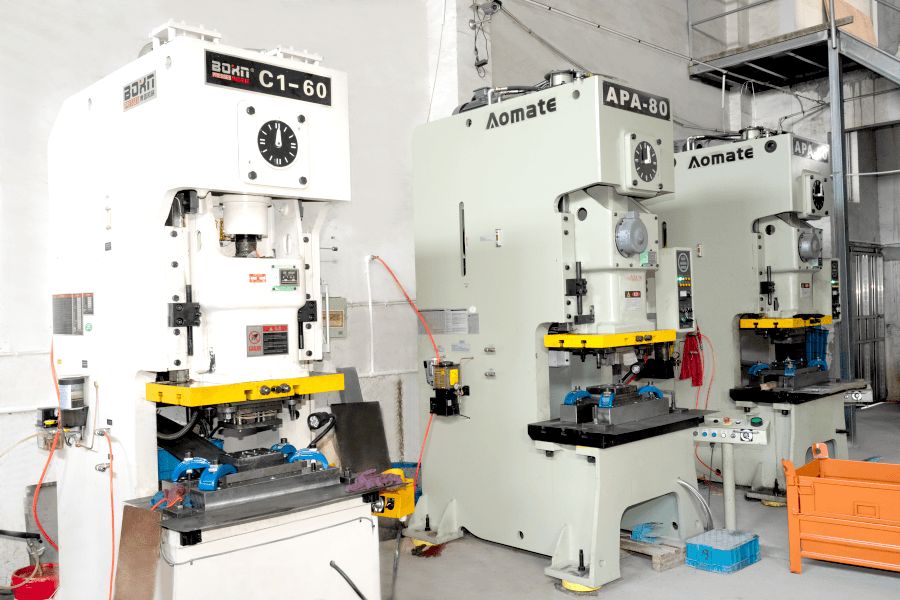

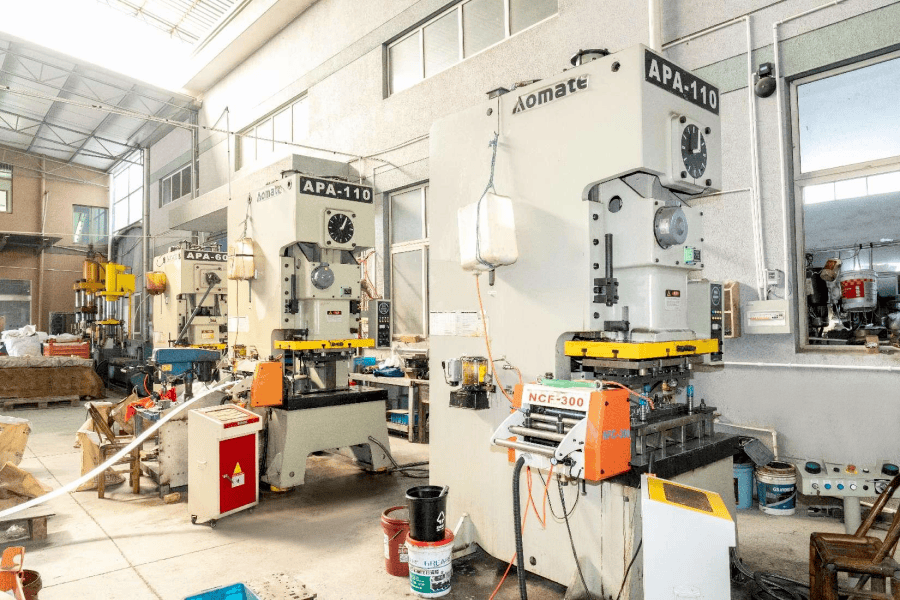

In high-precision stamping processing, the company adopts advanced multi-station-level die-making, single-mold technology and hydraulic press equipment. These equipment can achieve mass production while ensuring processing accuracy, significantly reduce production costs and improve production efficiency. Through multiple investments and technological improvements, the company ensures the accuracy and stability of each machine, and maintains a high degree of consistency during complex stamping processes. This allows us to provide our customers with one-stop service from raw materials to finished products.

In addition to standard stamping services, the company can also provide subsequent deep processing services according to customer needs, such as welding, riveting, tapping, hole punching, spraying, coating, etc. Whether customers need simple surface treatment or complex assembly operations, we can complete it through our own processing lines and technical teams. This integrated processing model not only improves the overall performance of the product, but also greatly shortens the lead time, reduces the intermediate links, and improves the overall production efficiency.

For the post-processing of high-precision stamping parts, the company not only pays attention to accuracy and quality, but also attaches great importance to surface treatment. In order to prevent scratches, wear and oxidation problems that may occur during stamping, we have adopted a variety of advanced surface treatment technologies, such as electroplating, spraying, anodizing, etc., to ensure that the product has a good appearance and long-term service life when delivered to customers. These treatment processes can not only enhance the aesthetics of the product, but also improve its functional characteristics such as corrosion resistance and wear resistance, and meet the needs of different application occasions.

The company also provides assembly services, especially when dealing with complex parts, we are able to provide assembly from single parts to complete subassemblies. The company has an experienced assembly team that can maintain high precision while ensuring that every assembly can be put into use smoothly. Through these additional services, we can help customers save more production time and costs, making them more focused on marketing and sales.

We pay great attention to quality control, start from every production link, and strictly implement it in accordance with international quality standards. Whether it is the dimensional tolerance, appearance quality of stamping parts, or the fineness of post-processing and uniformity of surface treatment, they will be strictly inspected and verified. The company has a complete quality inspection system to ensure that every product that leaves the factory can meet customer requirements and industry standards.

Through the above integrated processing services, the company not only meets customers' needs in product accuracy and diversity, but also reduces customers' production costs and enhances the overall market competitiveness of the products through a comprehensive service system. With strong technical support and high-quality service system, we have won a wide reputation in the industry and have become a long-term partner of many customers. We look forward to working with more customers to provide them with customized high-precision stamping parts and integrated processing services to help them improve product quality and production efficiency.

Does the company have in-mold sensors for real-time monitoring of high-precision stamping?

In the high-precision stamping production process, real-time monitoring technology has become an important means to improve processing stability and product quality. Ningbo Mingli Electric Technology Co., Ltd. keeps up with the industry development trend and actively introduces in-mold sensor technology to achieve dynamic monitoring and intelligent control of the entire punching process, thereby improving stamping efficiency, reducing unqualification rates, and ensuring the safety of molds and equipment use.

The in-mold sensor is an induction device installed inside the stamping mold, which can obtain key parameters such as the mold running status, punching pressure degree, material deformation, and position displacement in real time during the stamping process. By collecting these data, the company can promptly determine whether there are any abnormalities during the production process, such as the problem of not carrying the material, the mold is not closed, and the punching pressure is uneven. If the system monitors any potential risks, an early warning or aborts the stamping action immediately, thereby effectively preventing the generation of waste and the damage to the mold.

The company combines in-module sensor technology with modern control systems to transmit data to the monitoring terminal in real time through digital signal output, allowing operators to fully understand the current stamping conditions. This technology not only improves the controllability of the entire stamping process, but also provides a reliable basis for subsequent data analysis, which helps to further optimize process parameters and improve production efficiency.

In the production of high-precision stamping parts, dimensional control, tolerance maintenance and structural integrity are extremely demanding. Through the in-mode sensor system, continuous monitoring and precise adjustment can be achieved to avoid product inconsistencies caused by human error or equipment fluctuations. Every subtle deviation can be quickly captured by the sensor, so that dynamic correction is completed through an automatic feedback mechanism to ensure consistency and stability of stamping parts throughout the batch.

The company has also introduced in-mold testing mechanisms in multiple production links and coordinated with the mold maintenance plan for systematic management. During use, the status of each set of molds used for high-precision stamping will be continuously tracked by the in-mold sensor to detect parameters such as wear degree, operating frequency, and stress distribution. Relevant data is integrated into the information system to provide data support for mold maintenance and replacement. This method avoids sudden failures and improves the service life of the mold.

It is worth mentioning that while introducing sensor systems, Ningbo Mingli Electric Technology Co., Ltd. has also invested a lot of resources to train employees to enable operators to use and maintain sensor systems. In practical applications, this not only reduces production interruptions, but also improves the overall team's response speed and problem-solving capabilities.

The use of in-mold sensors is not only a reflection of technological progress, but also a direct reflection of the company's emphasis on product quality and production safety. It moves the stamping process from traditional experience dependence to data-driven, making the production process more controllable and traceable, and bringing higher trust to customers. Through the application of this system, the company not only made significant progress in improving product stability and processing accuracy, but also further promoted the development of intelligent manufacturing and digital workshops.

Eng

Eng  中文简体

中文简体